Abstract

In this study, microstructure and texture evolution of TB8 titanium alloys during hot deformation were investigated by using electron back-scattered diffraction (EBSD) analysis. The results showed that dynamic recrystallization (DRX) behavior of TB8 titanium alloys was drastically sensitive to the strain. As the true strain raised from 0.2 to 0.8, the degree of DRX gradually increased. The nucleation mechanism of recrystallization was observed, including discontinuous dynamic recrystallization (DDRX) resulting from the bulging of original boundaries. Furthermore, continuous dynamic recrystallization (CDRX) occurred because of the transformation of low-angle grain boundaries (LAGBs) to high-angle grain boundaries (HAGBs) in the interior of the original deformed grains. The texture evolution of TB8 titanium alloy during hot deformation process was analyzed in detail, and five texture components were observed, including {001}\(\left\langle { 100} \right\rangle\), {011}\(\left\langle { 100} \right\rangle\), {112}\(\left\langle { 1 10} \right\rangle\), {111}\(\left\langle { 1 10} \right\rangle\), and {111}\(\left\langle { 1 1 2} \right\rangle\). As the true strain increased, deformation textures were gradually weakened due to an increase in the volume fraction of DRX grains. When the true strain was 0.8, the main texture components consisted of the recrystallization texture components of the {001}\(\left\langle { 100} \right\rangle\) and {011}\(\left\langle { 100} \right\rangle\) textures.

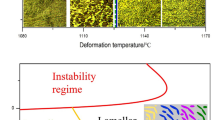

Graphic Abstract

Similar content being viewed by others

References

Xu TW, Li JS, Zhang FS, Wang FY, Liu XH, Feng Y. Microstructure evolution during cold-deformation and aging response after annealing of TB8 titanium alloy. Rare Metal Mat Eng. 2016;45(3):0575.

Tang B, Tang B, Han FB, Yang GJ, Li JS. Influence of strain rate on stress induced martensitic transformation in β solution treated TB8 alloy. J Alloys Compd. 2013;565:1.

Wu Y, Kou HC, Wu ZH, Tang B, Li JS. Dynamic recrystallization and texture evolution of Ti–22Al–25Nb alloy during plane–strain compression. J Alloys Compd. 2018;749:844.

Chen JH, Li JS, Tang B, Chen Y, Kou HC. Microstructure and texture evolution of a near β titanium alloy Ti–7333 during continuous cooling hot deformation. Prog Nat Sci Mater. 2019;29(1):50.

Ghasemi E, Zarei-Hanzaki A, Farabi E, Tesař K, Jäger A, Rezaee M. Flow softening and dynamic recrystallization behavior of BT9 titanium alloy: a study using process map development. J Alloys Compd. 2017;695:1706.

Wang G, Xu L, Tian YX, Zheng Z, Cui YY, Yang R. Flow behavior and microstructure evolution of a P/M TiAl alloy during high temperature deformation. Mater Sci Eng, A. 2011;528:6754.

Zhang Y, Wang XP, Kong FT, Sun LL, Chen YY. Microstructure, texture and mechanical properties of Ti–43Al–9 V–0.2Y alloy hot-rolled at various temperatures. J Alloys Compd. 2019;777:795.

Qu WT, Sun XG, Hui SX, Wang ZG, Yan L. High-temperature deformation behavior of a beta Ti–3.0Al–3.5Cr–2.0Fe–0.1B alloy. Rare Met. 2018;37(3):217.

Mantri SA, Banerjee R. Microstructure and micro-texture evolution of additively manufactured β–Ti alloys. Addit Manuf. 2018;23:86.

Yin LX, Liang SX, Zheng LY, Shi YD, Xie HL, Ma MZ, Liu RP. Microstructural and textural evolutions of TZ410 alloy under various rolling conditions. Mate. Charact. 2016;121:199.

Lu SY, Ma FC, Liu P, Li W. Microstructure and mechanical properties of TiB reinforced titanium matrix composites with heat treatment. Chin J Rare Met. 2018;42(4):379.

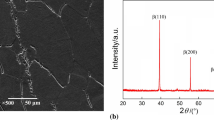

Duan YP, Ping L, Xue KM, Zhang Q, Wang XX. Flow behavior and microstructure evolution of TB8 alloy during hot deformation process. Trans Nonferrous Met Soc. 2007;17(6):1199.

Tang B, Tang B, Han FB, Li JS, Yang GJ. Hot deformation behavior of TB8 alloy near the β–transus. Rare Metal Mat Eng. 2013;42(9):1761.

Yang QY, Ma M, Tan YB, Xiang S, Zhao F, Liang YL. Initial β grain size effect on high-temperature flow behavior of TB8 titanium alloys in single β phase field. Metals. 2019;9(8):891.

Lin YC, Wu XY, Chen XM, Chen J, Wen DX, Zhang JL, Li LT. EBSD study of a hot deformed nickel-based superalloy. J Alloys Compd. 2015;640:101.

Lin YC, He DG, Chen MS, Chen XY, Zhao CY, Ma X, Long ZL. EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel–based superalloy during hot compressive deformation. Mater Des. 2016;97:13.

Lin YC, Chen XM. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des. 2011;32:1733.

Chen XM, Lin YC, Chen MS, Li HB, Wen DX, Zhang JL, He M. Microstructural evolution of a nickel–based superalloy during hot deformation. Mater Des. 2015;77:41.

Sander B, Raabe D. Texture inhomogeneity in a Ti–Nb–based β–titanium alloy after warm rolling and recrystallization. Mater Sci Eng, A. 2008;479:236.

Yuan C, Gao X, Li JH, Bao XQ. Secondary recrystallization of Goss texture in magnetostrictive Fe–Ga-based sheets. Rare Met. 2020;39(11):1288.

Xu YF, Yi DQ, Liu HQ, Wu XY, Wang B, Yang FL. Effects of cold deformation on microstructure, texture evolution and mechanical properties of Ti–Nb–Ta–Zr–Fe alloy for biomedical applications. Mater Sci Eng, A. 2012;547:64.

Gupta A, Khatirkar RK, Kumar A, Thool K, Bibhanshu N, Suwas S. Microstructure and texture development in Ti–15 V–3Cr–3Sn–3Al alloy–possible role of strain path. Mater Charact. 2019;156:109884.

Hölscher M, Raabe D, Lücke K. Relationship between rolling textures and shear textures in f.c.c. and b.c.c. metals. Acta Metall Mater. 1994;42(3):879.

Chen Y, Li JS, Tang B, Kou HC, Xue XY, Cui YW. Texture evolution and dynamic recrystallization in a beta titanium alloy during hot-rolling process. J Alloys Compd. 2015;618:146.

Barnett MR, Jonas JJ. Influence of ferrite rolling temperature on grain size and texture in annealed low C and IF steels. ISIJ Int. 1997;37(7):706.

Barnett MR. Role of in-grain shear bands in the nucleation of 〈111〉//ND recrystallization textures in warm rolled steel. ISIJ Int. 1998;38(1):78.

Humphreys FJ, Hatherly M. Recrystallization and Related Annealing Phenomena. 2nd ed. Oxford: Elsevier; 2004. 251.

Hasegawa M, Yamamoto M, Fukutomi H. Formation mechanism of texture during dynamic recrystallization in γ–TiAl, nickel and copper examined by microstructure observation and grain boundary analysis based on local orientation measurements. Acta Mater. 2003;51(13):3939.

Li K, Yang P. The formation of strong 100 texture by dynamic strain-induced boundary migration in hot compressed Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Metals-Basel. 2017;7(10):412.

Gu B, Chekhonin P, Schaarschuch R, Oertel CG, Xin SW, Ma CL, Zhou L, Gan WM, Skrotzki W. Microstructure, texture and hardness of a metastable β–titanium alloy after bar-rolling and annealing. J Alloys Compd. 2020;825:154082.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51804087), the Science and Technology Cooperative Foundation of Guizhou province (Nos. [2017]7240 and [2017]5788), the Basic Research Program of Guizhou Province (No. [2019]1091), and the Youth Science and Technology Talent Growth Project of Guizhou Education Bureau (No. [2018]107).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, QY., Ma, M., Tan, YB. et al. Microstructure and texture evolution of TB8 titanium alloys during hot compression. Rare Met. 40, 2917–2926 (2021). https://doi.org/10.1007/s12598-020-01643-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01643-7