Abstract

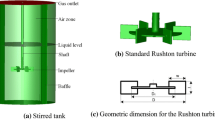

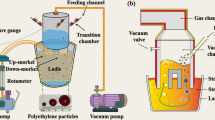

The suspension characteristics of ultrafine powder slurry in the stirred vessel were simulated by using computational fluid dynamics. The results show that the Rushton disk turbine impeller is more conducive to maintaining suspended homogeneity and circulation of slurry compared with the pitch blade turbine pumping up impeller and the pitch blade turbine pumping down impeller. And the increase in stirring speed enhances turbulent fluctuation and anisotropic velocity of the fluid at the cost of more power consumption, which improves dispersibility and suspensibility of the particles. Meanwhile, the change of impeller clearance has a weak influence on the flow pattern, and the impeller clearance of 0.32T (T is the diameter of the bottom of the reactor) can achieve better dispersivity and suspensibility of the particles with lower power consumption and larger axial velocity. The experiments of surface coating modification of ultrafine titanium dioxide (TiO2) were carried out under the same conditions for those of the simulation system. The surface film morphology and photocatalytic properties of the modified TiO2 were analyzed, and the obtained data are well consistent with the simulation results.

Similar content being viewed by others

References

Gu DY, Liu ZH, Xie ZM, Li J, Tao CY, Wang YD. Numerical simulation of solid–liquid suspension in a stirred tank with a dual punched rigid-flexible impeller. Adv Powder Technol. 2017;28(10):2723.

Divyamaan W, Moses OT, Vishnu KP, Ranjeet PU. CFD simulation of solid–liquid stirred tanks for low to dense solid loading systems. Particuology. 2016;29:16.

Liu HZ, Zhang B, Jing XJ, Wang W, Wang LJ. Adsorption and desorption properties for rhenium using a kind of weak-base anion resin. Rare Met. 2018;37(8):707.

Mishra P, Ein-Mozaffari F. Using computational fluid dynamics to analyze the performance of the Maxblend impeller in solid-liquid mixing operations. Int J Multiph Flow. 2017;91:194.

Hsu RC, Chiu CK, Lin SC. A CFD study of the drawdown speed of floating solids in a stirred vessel. J Taiwan Inst Chem Eng. 2018;90:1.

Tamburini A, Cipollina A, Micale G, Brucato A, Ciofalo M. CFD simulations of dense solid–liquid suspensions in baffled stirred tanks: prediction of the minimum impeller speed for complete suspension. Chem Eng J. 2012;193:234.

Huang X, Zhang XY, Huang D, Gao HX, Gong XP. Performances of micro-arc oxidation coating formed on aluminum alloy with nano-TiO2 and La(NO3)3 compound additive. Chin J Rare Met. 2017;41(1):25.

Divyamaan W, Utikar RP, Moses OT, Vishnu KP. CFD simulation of solid–liquid stirred tank. Adv Powder Technol. 2012;23(4):445.

Dohi N, Takahashi T, Minekawa K, Kawase Y. Power consumption and solid suspension performance of large-scale impellers in gas–liquid–solid three phase stirred tank reactors. Chem Eng J. 2017;97(2–3):103.

Cortada-Garcia M, Doreb V, Mazzei L, Angelia P. Experimental and CFD studies of power consumption in the agitation of highly viscous shear thinning fluids. Chem Eng Res Des. 2017;119:171.

Gu DY, Liu ZH, Qiu FC, Li J. Design of impeller blades for efficient homogeneity of solid–liquid suspension in a stirred tank reactor. Adv Powder Technol. 2017;28(10):2723.

Li LC, Xu B. CFD simulation of floating particles suspension in a stirred tank. Chem Pap. 2017;71(8):1377.

Xie L, Luo ZH. Modeling and simulation of the influences of particle–particle interactions on dense solid–liquid suspensions in stirred vessels. Chem Eng Sci. 2018;176:439.

Qiao SC, Wang RJ, Yan YF, Yang XX. Computational fluid dynamics analysis to effects of geometrical design and physical property on complete suspension of floating solids in stirred tanks. Asia-Pac J Chem Eng. 2014;9:866.

Ma Hiroaki, Kō H, Hideto Y. Powder Technology Handbook. Boca Raton: Taylor and Francis Group Press; 2006. 3.

Song R, Yang D, He L. Effect of surface modification of nanosilica on crystallization, thermal and mechanical properties of poly (vinylidene fluoride). J Mater Sci. 2007;42(20):8408.

Yang H, Mao J. Properties of AlPO4/CePO4 hybrid coating on rutile TiO2. Surf Eng. 2017;33:226.

Gao H, Qiao B, Wang TJ, Wang DZ, Jin Y. Cerium oxide coating of titanium dioxide pigment to decrease its photocatalytic activity. Ind Eng Chem Res. 2014;53:189.

Andrew Hanson. European GCC a fine filler. Ind Minerals. 1996;6:50.

Heike PK, Muller F, Reinhard P. Scale-up for grinding in stirred ball mills. Aufbereit Tech Mineral Process. 1996;37(10):469.

Yekeler M, Ozkan A, Austin LG. Kinetics of fine wet grinding in a laboratory ball mill. Powder Technol. 2001;114(1/2/3):224.

Bernhardt C, Reinsch E, Husemann K. Fine grinding in mineral processing using stirred ball mills. Powder Technol. 1999;105:357.

Xu Q, Zhao J, Xu H, Zhou H. Dispersion of TiO2 particles and preparation of SiO2 coating layers on the surfaces of TiO2. Mater Res Innov. 2015;19:142.

Dong XB, Sun ZM, Jiang L, Li CQ. Investigation on the film-coating mechanism of alumina-coated rutile TiO2 and its dispersion stability. Adv Powder Technol. 2017;28(8):1982.

Zhang YS, Yin HB, Wang AL, Liu C, Yu LB, Jiang TS, Hang Y. Evolution of zirconia coating layer on rutile TiO2 surface and the pigmentary property. J Phys Chem Solids. 2010;71:1458.

Wu HX, Wang TJ, Jin Y. Film-coating process of hydrated alumina on TiO2 particles. Ind Eng Chem Res. 2006;45:1337.

Liang Y, Qiao B, Wang TJ, Gao H, Yu KY. Effects of porous films on the light reflectivity of pigmentary titanium dioxide particles. Appl Surf Sci. 2016;387:581.

Wei BX, Zhao L, Wang TJ, Gao H, Wu HX, Jin Y. Photo-stability of TiO2 particles coated with several transition metal oxides and its measurement by rhodamine-B degradation. Adv Powder Technol. 2013;24:708.

Wu WC, Cui J, Jiang H, Jiang HB, Li CZ. Preparation of monodispersed titanium dioxide by wet grinding and its influencing factors. China Powder Sci Technol. 2018;24(2):60.

Zhang HW. CFD Simulation and Experimental Verification of Single-Phase Flow Field in Impeller Stirred Media Mill. Guangzhou: South China University of Technology; 2013. 18.

Tamburini A, Cipollina A, Micale G, Brucato A. CFD simulations of dense solid-liquid suspensions in baffled stirred tanks: prediction of solid particle distribution. Chem Eng J. 2013;223:875.

Ding Y. Numerical Simulation of Solid–Liquid Two Phase Flow in Dual-Impeller System. Shanghai: East China University of Science & Technology; 2015. 21.

Wang SY, Jiang XX, Wang RC, Wang X, Yang SW, Zhao J, Liu Y. Numerical simulation of flow behavior of particles in a liquid–solid stirred vessel with baffles. Adv Powder Technol. 2017;28(6):1611.

Sahu AK, Kumar P, Patwardhan AW, Joshi JB. CFD modelling and mixing in stirred tanks. Chem Eng Sci. 1999;54(13–14):2285.

Montante G, Lee KC, Brucato A, Yianneskis M. Numerical simulations of the dependency of flow pattern on impeller clearance in stirred vessels. Chem Eng Sci. 2001;56(12):3751.

Javed KH, Mahmud T, Zhu JM. Numerical simulation of turbulent batch mixing in a vessel agitated by a Rushton turbine. Chem Eng Sci. 2006;45(2):99.

Soos M, Moussa AS, Ehrl L, Sefcik J, Wu H, Morbidelli M. Effect of shear rate on aggregate size and morphology investigated under turbulent conditions in stirred tank. J Colloid Interface Sci. 2008;319(2):577.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 21838003, 91834301 and 21878092), the Shanghai Scientific and Technological Innovation Project (No. 18JC1410600), the Social Development Program of Shanghai (Nos. 17DZ1200900 and 18DZ2252400), the Innovation Program of Shanghai Municipal Education Commission and the Fundamental Research Funds for the Central Universities (No. 222201718002).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, WC., Cui, J., Jiang, H. et al. Computational fluid dynamics simulation and experimental analysis of ultrafine powder suspension. Rare Met. 39, 850–860 (2020). https://doi.org/10.1007/s12598-019-01323-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01323-1