Abstract

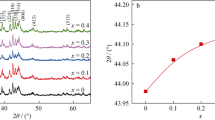

The crystal orientation of Ni50Mn25In25 and Ni50Mn34In16 melt-spun ribbons which appears parent phase at room temperature was investigated in this paper. The grains grow perpendicular to the surface of the ribbon and show columnar crystals distinctly. X-ray diffraction and electron backscattered diffraction were used to identify the orientation information of the ribbons. It is indicated that the well-developed preferred orientation of these columnar crystals is parallel to <001> direction, and this is in accordance with that in other shape memory ribbons, which was named as Eucken–Hirsch texture. This kind of texture predicts that it is beneficial to the magnetic field-induced strain compared with the common polycrystals. The results obtained in this paper provide reference for the preparation of Ni–Mn–In melt-spun ribbons.

Similar content being viewed by others

References

Kainuma R, Imano Y, Ito W, Sutou Y, Morito H, Okamoto S, Kitakami O, Oikawa K, Fujita A, Kanomata T, Ishida K. Magnetic-field-induced shape recovery by reverse phase transformation. Nature. 2006;439(7079):957.

Recarte V, Pérez-Landazábal JI, Sánchez-Alarcos V, Rodríguez-Velamazán JA. Dependence of the martensitic transformation and magnetic transition on the atomic order in Ni–Mn–In metamagnetic shape memory alloys. Acta Mater. 2012;60(5):1937.

Sutou Y, Imano Y, Koeda N, Omori T, Kainuma R, Ishida K, Oikawa K. Magnetic and martensitic transformations of NiMnX(X = In, Sn, Sb) ferromagnetic shape memory alloys. Appl Phys Lett. 2004;85(19):8879.

Krenke T, Duman E, Acet M, Wassermann EF, Moya X, Manosa L, Planes A, Suard E, Ouladdiaf B. Magnetic superelasticity and inverse magnetocaloric effect in Ni–Mn–In. Phys Rev B. 2006;73(17):174413.

Tan CL, Huang YW, Tian XH, Jiang JX, Cai W. Origin of magnetic properties and martensitic transformation of Ni–Mn–In magnetic shape memory alloys. Appl Phys Lett. 2012;100(13):132402.

Yan HL, Zhang YD, Xu N, Senyshyn A, Brokmeier H-G, Esling C, Zhao X, Zuo L. Crystal structure determination of incommensurate modulated martensite in Ni–Mn–In Heusler alloys. Acta Mater. 2015;88:375.

Huang YJ, Hu QD, Hou JW, Li JG. High isothermal internal friction over a large temperature range for dual-phase Ni–Mn–In magnetic shape memory alloy. Scripta Mater. 2014;87:21.

Miyamoto T, Ito W, Umetsu RY, Kainuma R, Kanomata T, Ishida K. Phase stability and magnetic properties of Ni50Mn50-xInx Heusler-type alloys. Scripta Mater. 2010;62(3):151.

Ullakko K, Huang JK, Kantner C, Ohandley RC, Kokorin VV. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl Phys Lett. 1996;69(13):117637.

O’Handley RC. Model for strain and magnetization in magnetic shape-memory alloys. J Appl Phys. 1998;83(6):367094.

Murray SJ, Marioni M, Allen SM, O’Handley RC, Lograsso TA. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni–Mn–Ga. Appl Phys Lett. 2000;77(6):886–8.

Schlagel DL, Wu YL, Zhang W, Lograsso TA. Chemical segregation during bulk single crystal preparation of Ni–Mn–Ga ferromagnetic shape memory alloys. J Alloy Compd. 2000;312(1–2):1016.

Liang T, Jiang CB, Xu HB, Liu ZH, Zhang M, Cui YT, Wu GH. Phase transition strain and large magnetic field induced strain in Ni50.5Mn24Ga25.5 unidirectionally solidified alloy. J Magn Magn Mater. 2004;268((1–2)):1016.

Liu Y. The superelastic anisotropy in a NiTi shape memory alloy thin sheet. Acta Mater. 2015;95:022.

Bhattacharya K, Kohn RV. Texture and the recoverable strain of shape memory polycrystals. Acta Mater. 1996;44(2):529.

O’Handley RC. Model for strain and magnetization in magnetic shape-memory alloys. J Appl Phys. 1998;83(6):3263.

Zhang XX, Qian MF, Zhang Z, Wei LS, Geng L. Magnetostructural coupling and magnetocaloric effect in Ni–Mn–Ga–Cu microwires. Appl Phys Lett. 2016;108(5):052401.

Qian MF, Zhang XX, Wei LS, Martin PG, Sun JF, Geng L, Scott TB, Panina LV, Peng HX. Microstructural evolution of Ni–Mn–Ga microwires during the melt-extraction process. J Alloys Compd. 2016;660:244.

Sanchez Llamazares JL, Sanchez T, Santos JD. Martensitic phase transformation in rapidly solidified Mn50Ni40In10 alloy ribbons. Appl Phys Lett. 2008;92(1):2827179.

Hernando B, Sánchez Llamazares JL, Santos JD, Sánchez ML, Escoda Ll, Suñol JJ, Varga R, García C, González J. Grain oriented NiMnSn and NiMnIn Heusler alloys ribbons produced by melt spinning: martensitic transformation and magnetic properties. J Magn Magn Mater. 2009;321(7):763.

Zhao XG, Hsieh CC, Lai JH, Cheng XJ, Chang WC, Cui WB, Liu W, Zhang ZD. Effects of annealing on the magnetic entropy change and exchange bias behavior in melt-spun Ni–Mn–In ribbons. Scripta Mater. 2010;63(2):250.

Liu J, Scheerbaum N, Hinz D, Gutfleisch O. Magnetostructural transformation in Ni–Mn–In–Co ribbons. Appl Phys Lett. 2008;92(16):2913162.

Bruno NM, Huang YJ, Dennis CL, Li JG, Shull RD, Jr Ross J H, Chumlyakov YI, Karaman I. Effect of grain constraint on the field requirements for magnetocaloric effect in Ni45Co5Mn40Sn10 melt-spun ribbons. J Appl Phys. 2016;120(7):28781380.

Balagna C, Fais A, Brunelli K, Peruzzo L, Horynova M, Celko L, Spriano S. Electro-sinter-forged Ni–Ti alloy. Intermetallics. 2016;68:31.

Gao F, Yang SJ, Li JJ, Qin MJ, Zhang Y, Sun HJ. Fabrication, dielectric, and thermoelectric properties of textured SrTiO3 ceramics prepared by RTGG method. Ceram Int. 2015;41(1):127.

Garcia CB, Arizab E, Tavares CJ, Villechaise P. Electron backscatter diffraction analysis of ZnO: Al thin films. Appl Surf Sci. 2012;259:590.

Wilkinson AJ, Britton TB. Strains, planes, and EBSD in materials science. Mater Today. 2012;15(9):366–76.

Krenke T, Acet M, Wassermann EF, Moya X, Mañosa L, Planes A. Ferromagnetism in the austenitic and martensitic states of Ni–Mn–In alloys. Phys Rev B. 2006;73(17):174413.

Feng Y, Sui JH, Gao ZY, Dong GF, Cai W. Microstructure, phase transitions and mechanical properties of Ni50Mn34In16−yCoy alloys. J Alloys Compd. 2009;476(1–2):935.

Cai W, Feng Y, Sui JH, Gao ZY, Dong GF. Microstructure and martensitic transformation behavior of the Ni50Mn36In14 melt-spun ribbons. Scripta Mater. 2008;58(10):830.

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Nos. 51301134 and 51401122).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Y., Fang, C., Ai, YL. et al. Crystal orientation in Ni–Mn–In melt-spun ribbons. Rare Met. 42, 1398–1402 (2023). https://doi.org/10.1007/s12598-018-1026-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1026-x