Abstract

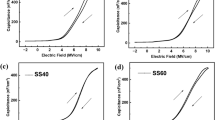

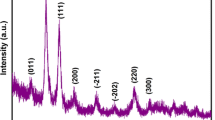

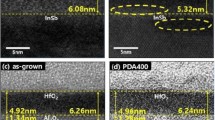

The effect of N2-plasma-treated SiO2 interfacial layer on the interfacial and electrical characteristics of HfO2/SiO2/p-Si stacks grown by atomic layer deposition (ALD) was investigated. The microstructure and interfacial chemical bonding configuration of the HfO2/SiO2/Si stacks were also examined by high-resolution transmission electron microscopy (HRTEM) and X-ray photoelectron spectroscopy (XPS). Compared with the samples without N2-plasma treatment, it is found that the samples with N2-plasma treatment have less oxygen vacancy density for SiO2 interfacial layer and better HfO2/SiO2 interface. In agreement with XPS analyses, electrical measurements of the samples with N2-plasma treatment show better interfacial quality, including lower interface-state density (D it, 9.3 × 1011 cm−2·eV−1 near midgap) and lower oxide-charge density (Q ox, 2.5 × 1012 cm−2), than those of the samples without N2-plasma treatment. Additionally, the samples with N2-plasma treatment have better electrical performances, including higher saturation capacitance density (1.49 μF·cm−2) and lower leakage current density (3.2 × 10−6 A·cm−2 at V g = V fb − 1 V). Furthermore, constant voltage stress was applied on the gate electrode to investigate the reliability of these samples. It shows that the samples with N2-plasma treatment have better electrical stability than the samples without N2-plasma treatment.

Similar content being viewed by others

References

Triyoso DH, Hegde RI, Gregory R, Spencer G, Schaeffer JK, Raymond M. Factors impacting stabilization of tetragonal phase in HfxZr1-xO2 high-k dielectrics. In: Proceedings of the 2009 IEEE International Conference on IC Design and Technology; 2009. 89.

Robertson J, Wallace RM. High-K materials and metal gates for CMOS applications. Mater Sci Eng R-Rep. 2015;88:1.

Robertson J. High dielectric constant gate oxides for metal oxide Si transistors. Rep Prog Phys. 2006;69(2):327.

Liu X, Ramanathan S, Longdergan A, Srivastava A, Lee E, Seidel TE, Barton JT, Pang D, Gordon RG. ALD of hafnium oxide thin films from Tetrakis(ethylmethylamino)hafnium and ozone. J Electrochem Soc. 2005;152(3):G213.

Zhang JW, He G, Chen HS, Lv JG, Gao J, Ma R, Liu M, Sun ZQ. Comparison of microstructure and electrical characteristics of sputtering-derived HfGdO/HfTiO and HfTiO/HfGdO gate stacks. Ceram Int. 2015;41(8):10216.

Sarkar PK, Roy A. Electrical properties of radio-frequency sputtered HfO2 thin films for advanced CMOS technology. AIP Conference Proceedings. 2015;1675(1):030066.

Kim SH, Seok TJ, Jin HS, Kim WB, Park TJ. Electrical and physicochemical properties of atomic-layer-deposited HfO2 film on Si substrate with interfacial layer grown by nitric acid oxidation. Appl Surf Sci. 2016;365:376.

Park J, Park TJ, Cho M, Kim SK, Hong SH, Kim JH, Seo M, Hwang CS, Won JY, Jeong R, Choi JH. Influence of the oxygen concentration of atomic-layer-deposited HfO2 gate dielectric films on the electron mobility of polycrystalline-Si gate transistors. J Appl Phys. 2006;99(9):094501.

Taube A, Mroczyński R, Korwin-Mikke K, Gierałtowska S, Szmidt J, Piotrowska A. Effect of the post-deposition annealing on electrical characteristics of MIS structures with HfO2/SiO2 gate dielectric stacks. Mater Sci Eng B. 2012;177(15):1281.

Hiratani M, S-i Saito, Shimamoto Y, Torii K. Effective electron mobility reduced by remote charge scattering in high-κ gate stacks. Jpn J Appl Phys. 2002;41(Part 1, No. 7A):4521.

Tinoco JC, Estrada M, Iñiguez B, Cerdeira A. Conduction mechanisms of silicon oxide/titanium oxide MOS stack structures. Microelectron Reliab. 2008;48(3):370.

Pradhan SK, Tanyi EK, Skuza JR, Xiao B, Pradhan AK. Electrical behavior of atomic layer deposited high quality SiO2 gate dielectric. J Vac Sci Technol A Vac Surf Films. 2015;33(1):107.

Arimura H, Kitano N, Naitou Y, Oku Y, Minami T, Kosuda M, Hosoi T, Shimura T, Watanabe H. Excellent electrical properties of TiO2/HfSiO/SiO2 layered higher-k gate dielectrics with sub-1 nm equivalent oxide thickness. Appl Phys Lett. 2008;92(21):212902.

Luc QH, Do HB, Ha MTH, Hu CC, Lin YC, Chang EY. Plasma enhanced atomic layer deposition passivated HfO2/AlN/In0.53Ga0.47As MOSCAPs with sub-nanometer equivalent oxide thickness and low interface trap density. IEEE Electron Device Lett. 2015;36(12):1277.

Lu HH, Xu JP, Liu L, Wang LS, Lai PT, Tang WM. Improved interfacial quality of GaAs metal-oxide-semiconductor device with NH3-plasma treated yittrium-oxynitride as interfacial passivation layer. Microelectron Reliab. 2016;56:17.

Liu CW, Xu JP, Liu L, Lu HH. High-k gate dielectric GaAs MOS device with LaON as interlayer and NH3-plasma surface pretreatment. Chin Phys B. 2015;24(12):127304.

Ramani K, Singh RK, Craciun V. Hf–O–N and HfO + barrier layers for Hf–Ti–O gate dielectric thin films. Microelectron Eng. 2008;85(8):1758.

Chen JH, Yoo WJ, Chan DSH. Effects of N2, O2, and Ar plasma treatments on the removal of crystallized HfO2 film. J Vac Sci Technol A. 2006;24(1):133.

Zimmermann C, Bethge O, Winkler K, Lutzer B, Bertagnolli E. Improving the ALD-grown Y2O3/Ge interface quality by surface and annealing treatments. Appl Surf Sci. 2016;369:377.

Ma R, Liu M, He G, Fang M, Shang G, Fei G, Zhang L. Nitrogen-concentration modulated interfacial and electrical properties of sputtering-derived HfGdON gate dielectric. J Appl Phys. 2016;119(21):214103.

Matsuki T, Hettiarachchi R, Feng W, Shiraishi K, Yamada K, Ohmori K. Impact of nitrogen incorporation on low-frequency noise of polycrystalline silicon/TiN/HfO5/SiO2. Gate-stack metal-oxide-semiconductor field-effect transistors. Jpn J Appl Phys. 2011;50(10):10PB02.

Wu Y, Lucovsky G, Lee YM. The performance and reliability of PMOSFET’s with ultrathin silicon nitride/oxide stacked gate dielectrics with nitrided Si-SiO2 interfaces prepared by remote plasma enhanced CVD and post-deposition rapid thermal annealing. IEEE Trans Electron Devices. 2000;47(7):1361.

Lin C, Leou KC, Fan YC, Li TC, Chang KH, Lee LS, Tzeng PJ. Effects of in situ N2 plasma treatment on etch of HfO2 in inductively coupled Cl2/N2 plasmas. J Vac Sci Technol A Vac Surf Films. 2007;25(3):592.

Chou CH, Chang HH, Hsu CC, Yeh WK, Chien CH. Low-leakage tetragonal ZrO2 (EOT < 1 nm) with in situ plasma interfacial passivation on germanium. IEEE Electron Device Lett. 2016;37(2):138.

Ye C, Zhan C, Zhang J, Wang H, Deng T, Tang S. Influence of rapid thermal annealing temperature on structure and electrical properties of high permittivity HfTiO thin film used in MOSFET. Microelectron Reliab. 2014;54(2):388.

Hauser JR, Ahmed K. Characterization of Ultra-Thin Oxides Using Electrical C-V and I-V Measurements. AIP Conference Proceedings. 1998;449(1):235.

Terman LM. An investigation of surface states at a silicon silicon oxide interface employing matal oxide silicon diode. Solid-State Electron. 1962;5:285.

Han JH, Zhang R, Osada T, Hata M, Takenaka M, Takagi S. Impact of plasma post-nitridation on HfO2/Al2O3/SiGe gate stacks toward EOT scaling. Microelectron Eng. 2013;109:266.

Lin LM, Lai PT. High-k gate stack HfxTi1−xON/SiO2 for SiC MOS devices. J Mater Sci Mater Electron. 2008;19(8–9):894.

Gao J, He G, Sun ZQ, Chen HS, Zheng CY, Jin P, Xiao DQ, Liu M. Modification of electrical properties and carrier transportation mechanism of ALD-derived HfO2/Si gate stacks by Al2O3 incorporation. J Alloys Compd. 2016;667:352.

Seong NJ, Lee WJ, Yoon SG. Structural and electrical characterizations of ultrathin HfO2 gate dielectrics treated by nitrogen-plasma atmosphere. J Vac Sci Technol B Microelectron Nanometer Struct. 2006;24(1):312.

Li CX, Lai PT. Wide-bandgap high-k Y2O3 as passivating interlayer for enhancing the electrical properties and high-field reliability of n-Ge metal-oxide-semiconductor capacitors with high-k HfTiO gate dielectric. Appl Phys Lett. 2009;95(2):022910.

Xiao SZ, Feng F, Shi K, Deng ST, Qu TM, Zhu YP, Lu HY, Huang RX, Han ZH. Resputtering effect during MgO buffer layer deposition by magnetron sputtering for superconducting coated conductors. J Vac Sci Technol A. 2015;33(4):041504.

Acknowledgements

This study was financially supported by the National Science and Technology Major Project of China (No. 2013ZX02303-001-002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, XQ., Xiong, YH., Du, J. et al. Improving interfacial and electrical properties of HfO2/SiO2/p-Si stacks with N2-plasma-treated SiO2 interfacial layer. Rare Met. 42, 2081–2086 (2023). https://doi.org/10.1007/s12598-017-0958-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0958-x