Abstract

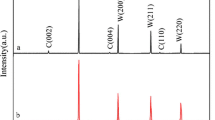

This study was conducted to investigate the influence of pulse parameters on the surface morphology and crystal orientation of the tungsten coatings electrodeposited on pure copper substrates. The deposited coatings were analyzed by X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy-dispersive spectrometer (EDS). SEM analysis indicates that pulse parameters have significant influences on the surface morphology of the deposited coatings. Meanwhile, the change in grain size of the tungsten coatings demonstrates that the change in frequency and duty cycle could cause the variation of nucleation rate and grain growth of deposits. Moreover, no obvious diffusion layer at the coating/substrate interface is found by line analysis of EDS. XRD results reveal that tungsten coatings are of bcc structure and the preferred orientation of the deposits varies with duty cycle and period.

Similar content being viewed by others

References

Matějíček J, Chraska P, Linke J. Thermal spray coatings for fusion applications—review. Therm Spray Technol. 2007;16(1):64.

Ongena J, Van Oost G. Energy for future centuries: will fusion be an inexhaustible, safe, and clean energy source? Fusion Sci Technol. 2004;45(2T):3.

Rebut PH. ITER: the first experimental fusion reactor. Fusion Eng Des. 1995;30(1):85.

Bolt H, Barabash V, Krauss W, Linke J, Neu R, Suzuki S, Yoshida N. Materials for the plasma-facing components of fusion reactors. In: Proceedings of the 11th International Conference on Fusion Reactor Materials. Kyoto; 2004. 66.

Smid I, Akiba M, Vieider G, Plöchl L. Development of tungsten armor and bonding to copper for plasma-interactive components. In: Proceedings of the 8th International Conference on Fusion Reactor Materials. Sendia; 1998. 160.

Davis JW, Barabash VR, Makhankov A, Plöchl L, Slattery KT. Assessment of tungsten for use in the ITER plasma facing components. In: Proceedings of the 8th International Conference on Fusion Reactor Materials. Sendia; 1998. 308.

Tokunaga K, Yoshida N, Noda N, Sogabe T, Kato T. High heat load properties of tungsten coated carbon materials. In: Proceedings of the 8th International Conference on Fusion Reactor Materials. Sendia; 1998. 998.

Ruset C, Grigore E, Maier H, Neu R, Greuner H, Mayer M, Matthews G. Development of W coatings for fusion applications. Fusion Eng Des. 2011;86(9):1677.

Maier H, Luthin J, Balden M, Linke J, Koch F, Bolt H. Properties of tungsten coatings deposited onto fine grain graphite by different methods. In: Proceedings of the 7th International Conference on Plasma Surface Engineering. Partenkirchen; 2001. 733.

Niu YR, Zheng XB, Ji H, Qi J, Ding CX, Chen JL, Luo GN. Microstructure and thermal property of tungsten coatings prepared by vacuum plasma spraying technology. Fusion Eng Des. 2010;85(7):1521.

Du JH, Li ZX, Liu GJ, Qi HJ, Ding CX, Chen JL, Luo GN. Surface characterization of CVD tungsten coating on molybdenum substrate. Surf Coat Technol. 2005;198(1):169.

Ganne T, Crépin J, Serror S, Zaoui A. Cracking behaviour of PVD tungsten coatings deposited on steel substrates. Acta Mater. 2002;50(16):4149.

Chen A, Zhu K, Zhong H, Shao Q, Ge G. A new investigation of oxygen flow influence on ITO thin films by magnetron sputtering. Sol Energy Mater Sol C. 2014;120(A):157.

Moon YT, Xie J, Liu C, Fu Y, Ni X, Biyikli N, Zhu K, Yun F, Sagar A, Feenstra RM. A study of the morphology of GaN seed on in situ deposited SixNy and its effect on properties of overgrowth of GaN epilayers. J Cryst Growth. 2006;291(1):301.

Kuryatkov V, Zhu K, Borisov B, Chandolu A, Gherasoiu I, Kipshidze G, Chu SNG, Hotlz M, Kudryavtsev Y, Asomoza R, Nikishin SA, Temkin H. Electrical properties of p-n junctions based on superlattices of AlN/AlGa(In)N. Appl Phys Lett. 2003;83(7):1319.

Tao S, Li DY. Tribological, mechanical and electrochemical properties of nanocrystalline copper deposits produced by pulse electrodeposition. Nanotechnology. 2006;17(1):65.

Chandrasekar MS, Pushpavanam M. Pulse and pulse reverse plating—conceptual, advantages and applications. Electrochim Acta. 2008;53(8):3313.

Davis GL, Gentry CHR. The electrodeposition of tungsten. Metallurgia. 1956;53(1):3.

Nakajima H, Nohira T, Hagiwara R. Electrodeposition of metallic tungsten in ZnCl2–NaCl–KCl–WCl4 melt at 250 °C. Electrochem Solid Sate Lett. 2005;8(7):C91.

Nakajima H, Nohira T, Hagiwara R, Nitta K, Inazawa S, Okada K. Electrodeposition of metallic tungsten films in ZnCl2-NaCl-KCl-KF-WO3 melt at 250°C. Electrochim Acta. 2007;53(1):24.

Jiang F, Zhang YC, Li XL, Sun NB, Wang LL. Tungsten coating prepared on V-4Cr-4Ti alloy substrate by electrodeposition from molten salt in air atmosphere. Fusion Eng Des. 2014;89(2):83.

Lassner E, Schubert WD. Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds. New York: Plenum Publishers; 1999. 85.

Moseley PT, Seabrook CJ. The crystal structure of β-tantalum. Acta Crystallogr Sect B. 1973;29(5):1170.

Hu GX, Cai X, Rong YH. Fundamentals of Materials Science. Shanghai: Shanghai Jiao Tong University Press; 2010. 5.

Natter H, Hempelmann R. Nanocrystalline copper by pulsed electrodeposition: the effects of organic additives, bath temperature, and pH. J Phys Chem. 1996;100(50):19525.

Moradi EH, Jafarzadeh K, Borji S, Abbaszadeh H. Pulse electrodeposition as a new approach in electrowinning of high purity cobalt from WC-Co scraps. Part I: the effect of frequency and duty cycle. Miner Eng. 2015;77:10.

Kim SH, Sohn HJ, Joo YC, Kim YW, Yim TH, Lee HY, Kang T. Effect of saccharin addition on the microstructure of electrodeposited Fe–36 wt% Ni alloy. Surf Coat Technol. 2005;199(1):43.

Rajalakshmi N, Dhathathreyan KS. Nanostructured platinum catalyst layer prepared by pulsed electrodeposition for use in PEM fuel cells. Int J Hydrog Energy. 2008;33(20):5672.

Liu YH, Zhang YC, Liu QZ, Li XL, Jiang F. The effects of electro-deposition current parameters on performance of tungsten coating. Int J Refract Met Hard Mater. 2012;35:241.

Yuan XT, Wang Y, Sun DB, Yu HY. Influence of pulse parameters on the microstructure and microhardness of nickel electrodeposits. Surf Coat Technol. 2008;202(9):1895.

Acknowledgements

This work was financially supported by the National Magnetic Confinement Fusion Program of China (No. 2015GB109003) and the National Natural Science Foundation of China (Nos. 51171006 and 51471015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, XQ., Zhang, Y., Zhu, KG. et al. Surface morphology and crystal orientation of electrodeposited tungsten coatings with different pulse parameters. Rare Met. 37, 407–412 (2018). https://doi.org/10.1007/s12598-016-0825-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0825-1