Abstract

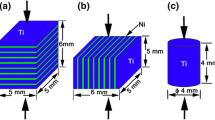

Ni-base metal–intermetallic laminate composites were obtained from in situ reaction synthesis between Ni and Al foils by utilizing plasma activated sintering. The effects of Ni foil thickness on the microstructure and tensile properties of the composites were investigated. The results show that the phases forming during reaction synthesis are independent of the starting thickness of the Ni foils. However, thicker reacted layers are obtained in the samples fabricated from 100 μm Ni foils (Ni100) than those obtained in the samples from 50 μm Ni foils (Ni50) when treated at the same process. The tensile strength of Ni100 samples increases with the temperature increasing at the expense of ductility. Dissimilarly, Ni50 composites treated at higher temperatures exhibit enhanced strength and ductility. Both Ni50 and Ni100 laminate fracture in a similar mechanism. Cracking first occurs in the brittle intermetallic layers. These original cracks result in shear bands in Ni layers emitted from the crack tips, and thus producing local stress concentration, which initiates new cracks in adjacent intermetallic layers. The multiplication of cracks and shear bands leads to the failure of the laminates.

Similar content being viewed by others

References

Ritchie RO. The conflicts between strength and toughness. Nature. 2011;10(11):817.

Kajuch J, Short J, Lewandowski JJ. Deformation and fracture behavior of Nb in Nb5Si3/Nb laminates and its effect on laminate toughness. Acta Metall Mater. 1995;43(5):1955.

Cai W, Feng X, Sui J. Preparation of multi-walled carbon nanotube-reinforced TiNi matrix composites from elemental powders by spark plasma sintering. Rare Met. 2012;31(1):48.

Li M, Soboyejo WO. An investigation of the effects of ductile-layer thickness on the fracture behavior of nickel aluminide microlaminates. Metall Mater Trans A. 2000;31(5):1385.

Vecchio K. Synthetic multifunctional metallic–intermetallic laminate composites. JOM. 2005;57(3):25.

Mumtaz K, Echigoya J, Nakata C, Husain SW. Effect of cold rolling and subsequent annealing on hot pressed Ni/Al laminates. J Mater Sci. 2001;36(16):3981.

Ma L. He Xd, Li Y. Optimized design and preparation of Ti/TiAl laminated composite. Trans Nonferrous Met Soc China. 2005;15(3):48.

Rawers J, Hansen J, Alman D, Hawk J. Formation of sheet-metal intermetallic composites by self-propagating high-temperature reactions. J Mater Sci Letts. 1994;13(18):1357.

Alman D, Dogan C, Hawk J, Rawers J. Processing, structure and properties of metal–intermetallic layered composites. Mater Sci Eng A. 1995;192–193(2):624.

Peng LM, Wang JH, Li H, Zhao JH, He LH. Synthesis and microstructural characterization of Ti–Al3Ti metal–intermetallic laminate (MIL) composites. Script Mater. 2005;52(3):243.

Patselov A, Greenberg B, Gladkovskii S, Lavrikov R, Borodin E. Layered metal–intermetallic composites in Ti-Al system: strength under static and dynamic load. AASRI Procedia. 2012;3:107.

Wang H, Han J, Du S, Northwood D. Reaction synthesis of nickel/aluminide multilayer composites using Ni and Al foils: microstructures, tensile properties, and deformation behavior. Metall Mater Trans A. 2007;38(2):409.

Konieczny M. Microstructural characterisation and mechanical response of laminated Ni-intermetallic composites synthesised using Ni sheets and Al foils. Mater Charact. 2012;70:117.

Chung D, Enoki M, Kishi T. Microstructural analysis and mechanical properties of in situ Nb/Nb-aluminide layered materials. Sci Technol Adv Mater. 2002;3(2):129.

Mizuuchi K, Inoue K, Sugioka M, Itami M, Lee J, Kawahara M. Properties of Ni-aluminides-reinforced Ni-matrix laminates synthesized by pulsed-current hot pressing (PCHP). Mater Sci Eng A. 2006;428(1–2):169.

Munir ZA, Quach DV, Ohyanagi M. Electric current activation of sintering: a review of the pulsed electric current sintering process. J Am Ceram Soc. 2011;94(1):1.

Zhu P, Li JCM, Liu CT. Adiabatic temperature of combustion synthesis of Al-Ni systems. Mater Sci Eng A. 2003;357(1–2):248.

Wang HB, Han JC, Du SY, Northwood D. Effects of Ni foil thickness on the microstructure and tensile properties of reaction synthesized multilayer composites. Mater Sci Eng A. 2007;445–446:517.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51002115), the Special Fund for Basic Scientific Research of Central Colleges, Chang’an University (No. 2011JC139), and the Foundation of State Key Laboratory for Mechanical Behavior of Materials (No. 20121203).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, YJ., Shi, ZQ., Xu, YK. et al. Correlation between microstructure and tensile behavior of metal–intermetallic laminate compound with different initial Ni foil thickness. Rare Met. 33, 196–202 (2014). https://doi.org/10.1007/s12598-013-0203-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0203-1