Abstract

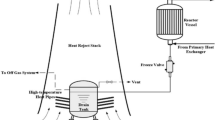

A numerical code has been developed for simulating natural circulation based decay heat removal system of a typical pool type sodium cooled fast reactor. The code consists of one-dimensional numerical models of a sodium–sodium shell and tube heat exchanger (DHX) dipped in a pool of sodium, finned tube type sodium to air heat exchanger (AHX), intermediate circuit connecting the two heat exchangers, a tall stack over the AHX and dampers for regulating natural draft air flow through the AHX. The code simulates steady state and transient natural circulation flow development in the DHX primary, intermediate and air circuits following any transients in the source temperature or in the air circuit. The code has been validated against in-house experiments conducted in a 355 kW natural circulation test loop SADHANA under various operating conditions. With the validated code, the performance of decay heat removal system has been evaluated at various source temperatures.

Similar content being viewed by others

Abbreviations

- a:

-

s1/d

- A:

-

Heat transfer surface area, m2

- b:

-

s2/d

- c p :

-

Specific heat of fluid, J/kg/K

- C:

-

Heat capacity, J/K

- d:

-

Diameter, m

- f:

-

Darcy coefficient for pressure drop

- F:

-

Weighting factor

- g:

-

Gravitational constant, 9.81, m/s2

- h:

-

Heat transfer coefficient, W/(m2K)

- h1 :

-

Fin height, m

- i:

-

Mesh index

- I:

-

Fluid inertia (L/A), m

- j:

-

Region number

- k:

-

Thermal conductivity, W/(mK)

- L:

-

Length, m

- \(\dot{m}\) :

-

Mass flow rate, kg/s

- N:

-

Number

- Nu:

-

Nusselt number, \( \frac{hd}{k} \)

- Pe:

-

Peclet number

- Pr:

-

Prandtl number, \( \frac{{\mu C_{p} }}{k} \)

- Q:

-

Mass flow rate, kg/s

- R:

-

Fouling resistance, m2K/W

- Re:

-

Reynolds number

- s:

-

Fin spacing (1/No of fins per meter)

- s1 :

-

Transverse pitch of the tubes, m

- s2 :

-

Longitudinal pitch of the tubes, m

- t:

-

Time, s

- T:

-

Temperature, K

- u:

-

Velocity, m/s

- U:

-

Overall heat transfer coefficient, w/m2K

- z:

-

Height, m

- Z:

-

Number of rows of tubes

- ΔPf :

-

Pressure drop, Pa

- ηf :

-

Fin efficiency

- ηf1 :

-

Effective fin efficiency

- ν:

-

Kinematic viscosity, m2/s

- amb:

-

Ambient air

- b:

-

Bare

- f:

-

Fin

- i:

-

Inner

- Na:

-

Sodium

- o:

-

Outer

- p:

-

Primary side

- s:

-

Secondary side

- T:

-

Tube

- w:

-

Wall

- n:

-

Time index

References

Chetal, S.C., Balasubramaniyan, V., Chellapandi, P., Mohanakrishnan, P., Puthiyavinayagam, P., Pillai, C.P., Raghupathy, S., Shanmugam, T.K., Sivathanu Pillai, C.: The design of prototype fast breeder reactor. Nucl. Eng. Des. 236, 852–860 (2006)

Partha Sarathy, U., Sundararajan, T., Balaji, C., Velusamy, K., Chellapandi, P., Chetal, S.C.: Decay heat removal in a pool type fast breeder reactor using passive systems. Nucl. Eng. Des. 250, 480–499 (2012)

Padmakumar, G., Vinod, V., Pandey, G.K., Krishnakumar, S., Chandramouli, S., Vijaykumar, G., Rajan, K.K.: SADHANA facility for simulation of natural convection in SGDHR system of PFBR. Prog. Nucl. Energy 66, 99–107 (2013)

Addition, S.L., Frisch, W.L.: Transient heat exchanger simulation employing analytical nodal average temperature in the finite difference equations. Trans. ANS 15, 259 (1972)

Marcellin, C., Guidez, J.: Hydrodynamic behavior of intermediate heat exchangers in pool type fast breeder reactor. In: Proceedings of the International Conference on Liquid Metal Engineering and Technology; BNES, London, pp. 211–214 (1984)

Zukauskas, A.: Heat Exchanger Design hand Book, vol. 2. Hemisphere Publishing Corporation, Washington (1983)

Idelchik, I.E.: Handbook of Hydraulic Resistance, 3rd edn. CRC Press, New York (1993)

Vinod, V., Chandran, T.: Study on performance of sensors used for measuring parameters for experiments in SADHANA. Internal report. IGC/FRTG/99142/EX/3047/R-A (2010)

Vinod, V., Krishnakumar, S., Punniamoorthy, R., Chandranouli, S., Vijaykumar, G.: Heat transport in SADHANA loop under steady state natural circulation condition. Internal report: IGC/FRTG/99142/EX/3051/R-A, (2010)

Vinod, V., Sathishkumar, S., Mourya, R.K., Chandramouli, S., Padmakumar, G., Nashine, B.K., Selvaraj, P.: Performance evaluation of decay heat removal system of PFBR with partial availability of air side dampers. Nucl. Eng. Des. 318, 174–181 (2017)

Vinod, V., Chandramouli, S., Padmakumar, G., Nahine, B.K., Rajan, K.K.: Experimental study on the transient response of passive decay heat removal system. Nucl. Eng. Des. 280, 564–569 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Partha Sarathy, U., Balaji, C., Sudararajan, T. et al. Numerical modeling of FBR safety grade decay heat removal system and its validation. Int J Adv Eng Sci Appl Math 10, 132–145 (2018). https://doi.org/10.1007/s12572-018-0212-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12572-018-0212-2