Abstract

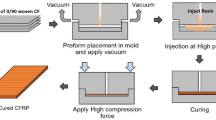

Cocuring process is a unique characteristic of composite materials wherein multiple parts like stringers, ribs and spars are simultaneously cured and bonded to a composite skin resulting in an integral structure. It has many benefits like reduction in part count, elimination of stress concentration due to fastener holes in the cocured regions and reduced assembly time and related costs. However, the application of cocuring has been limited on contoured components because of the complexities associated with the tooling. The basic requirements to be fulfilled are (a) consolidation of skins and stiffeners and (b) dimensional tolerance on position and thickness of stiffeners. Proper consolidation can be ensured through the faithful transfer of autoclave pressure by designing tools which are flexible so that they conform to desired shape whereas the positional tolerance can be achieved by using rigid tools. The resolution of such conflicting requirements requires a detailed study of the geometry of the part, design requirements and tolerances achievable on tools. This paper discusses design of tools for two types of cocured structures viz., open and closed cocured structures. The tooling technologies for realising above structures differ considerably. A few tooling concepts have been discussed based on the authors’ experience of developing cocured structures over the last two decades.

Similar content being viewed by others

References

Kageyama, M., Yoshida, S.: Development of XF-2 fighter composite structures (cocured composite wings).In: Proceedings of the 41st structures, structural dynamics, and materials conference and exhibit, AIAA, 2000

Lorell, M.: Troubled partnership: A history of U.S.-Japan collaboration on the FS-X Fighter. Project Airforce-RAND, 1995

Kotresh M. Gaddikeri., SubbaRao, M.: Cocuring technique for integrally stiffened shells. INCCOM-1, May 2002

Kutty, MG., Saravanakumar, N., Radhakrishnan, G., Dinesh, BL., Subbarao, M.: Development of composite tools for cocured and cobonded stiffened composite structure for aircraft using derivative tooling technology. INCCOM-7, December 2008

SubbaRao, M., Gowda, M.N.N.: Development of fin for LCA using advanced composites. J. Aeronaut. Soc. India 54(2), 106–108 (2002)

Gowda, MNN., Pitchai, P., Ravi, S., Pavithran, S., SubbaRao, M.: Issues in combining different fabrication techniques to produce co-cured structures. National seminar on composites product development, NASCOMP 96, April 1996

Acknowledgments

Concepts discussed in the paper have been experimented and fine tuned by scientists/technologists of Advanced Composites Division (ACD) of CSIR-NAL for a period of over two decades. These concepts have been translated to real-life applications on many aircraft programs successfully. Authors would like to acknowledge the inputs received from their esteemed colleagues on various aspects of cocuring. Authors would like to thank Director, NAL and Head, ACD for their unstinting support. Authors would like to show their appreciation to various groups of the Division that are involved in processing and NDE of composites. Authors express their heartfelt thanks to the staff of ACD who directly or indirectly involved in developing cocuring technologies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaddikeri, K.M., Gowda, M.N.N., Sundaram, R. et al. Innovative tooling concepts for cocured composite structures in aircraft applications. Int J Adv Eng Sci Appl Math 6, 142–147 (2014). https://doi.org/10.1007/s12572-015-0119-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12572-015-0119-0