Abstract

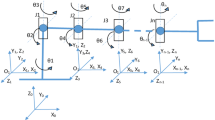

Planning the manipulators’ task sequences is necessary for proper execution of specific robotic tasks. With multiple manipulators for cooperative tasks, planning becomes difficult owing to possible collisions between component manipulators. This paper proposes a shadow space approach that utilizes the swept area of a robot during its motion, for collision-free task planning of dual manipulators. A collision can be detected and prevented by computing the intersection of two manipulators’ shadow spaces. Then, a novel genetic algorithm with mutually exclusive chromosomes is proposed to search optimal collision-free task sequences for dual manipulators. For a pragmatic example of placing pemnuts onto the back-chassis of a liquid crystal device (LCD) panel, experiments and simulation show that the proposed method can determine a nearly optimal sequence, which allows two manipulators to move cooperatively without collisions, even though they share a common workspace.

Similar content being viewed by others

References

R. Drath and A. Horch, “Industrie 4.0: hit or hype?” IEEE Industrial Electronics Magazine, vol. 8, no. 2, pp. 5658, 2014.

S. Kock, T. Vittor, B. Matthias, H. Jerregard, M. Kallman, I. Lundberg, R. Mellander, and M. Hedelind, “Robot concept for scalable, flexible assembly automation: a technology study on a harmless dual-armed robot,” Proc. of the IEEE International Symposium on Assembly and Manufacturing, pp. 1–5, May 2011.

R. Bloss, “Robotics innovations at the 2009.assembly technology expo,” Industrial Robot: An International Journal, vol. 37, no. 5, pp. 427–430, 2010.

H. M. Do, T. Y. Choi, and J. H. Kyung, “Automation of cell production system for cellular phones using dual-arm robots,” The International Journal of Advanced Manufacturing Technology, vol. 83, no. 5–8, pp. 1349–1360, Mar. 2016.

R. L. A. Shauri, K. Saiki, S. Toritani, and K. Nonami, “Sensor integration and fusion for autonomous screwing task by dual-manipulator hand robot,” Procedia Engineering, vol. 41, pp. 1412–1420, 2012.

Y. S. Choi, D. H. Kim, S. W. Hwang, H. G. Kim, N. W. Kim, and C. S. Han, “Dual-arm robot motion planning for collision avoidance using B-spline curve,” The International Journal of Precision Engineering and Manufacturing, vol. 18, no. 6, pp. 835–843, June 2017.

Y. Koga and J.-C. Latombe, “On multi-arm manipulation planning,” Proc. of the IEEE International Conference on Robotics and Automation, vol. 2, pp. 945–952, May 1994.

S. M. LaValle, Planning Algorithms, Cambridge University Press, 2006.

A. Brahmi, M. Saad, G. Gauthier, W. Zhu, and J. Ghommam, “Adaptive control of multiple manipulators transporting a rigid object,” International Journal of Control, Automation and Systems, vol. 15, no. 4, pp. 1779 -1789, 2017.

S. Alatartsev, S. Stellmacher, and O. Frank, “Robotic task sequencing problem: a survey,” Journal of Intelligent & Robotic Systems, vol. 80, no. 2, pp. 279–298, Nov. 2015.

D. L. Applegate, R. E. Bixby, V. Chvatal, and W. J. Cook, The Traveling Salesman Problem: A Computational Study, Princeton University Press, 2007.

L. Yang and H. Zhou, “Research on path planning and TSP based on genetic algorithm and Hopfield neural network,” Proc. of the IEEE Computer Science and Service System (CSSS), June 2011. pp. 657–659.

P. Brunn, “Collision avoidance for two robots sharing a common workspace,” IEE Colloquium on Fast Reconfiguration of Robotic and Automation Resources, pp. 2/1-2/4 1995.

G. Sanchez and J. C. Latombe, “Using a PRM planner to compare centralized and decoupled planning for multirobot systems,” Proc. of the IEEE International Conference on Robotics and Automation, pp. 2112–2119, 2002.

C. Smith, Y. Karayiannidis, L. Nalpantidis, X. Gratal, P. Qi, D. Dimarogonas, and D. Kragic, “Dual arm manipulation a survey,” Robotics and Autonomous Systems, vol. 60, no. 10, pp. 1340–1353, Oct. 2012.

E. Todt, G. Rausch, and R. Suarez, “Analysis and classification of multiple robot coordination methods,” Proc. of the IEEE International Conference on Robotics and Automation, pp. 3158–3163, 2000.

S. S. Chiddarwar and N. R. Babu, “Conflict free coordinated path planning for multiple robots using a dynamic path modification sequence,” Robotics and Autonomous Systems, vol. 59, pp. 508–518, 2011.

M. Davoodi, M. Abedin, B. Banyassady, P. Khanteimouri, and A. Mohades, “An optimal algorithm for two robots path planning problem on the grid,” Robotics and Autonomous Systems, vol. 61, pp. 1406–1414, 2013.

C. Park, “Self-collision detection & avoidance algorithm for a robot manipulator,” International Journal of Engineering and Innovative Technology, vol. 5, no. 4, pp. 139–142, 2015.

T. Bektas, “The multiple traveling salesman problem: an overview of formulation and solution procedures,” The International Journal of Management Science, vol. 34, no. 3, pp. 209–219, June 2006.

T. Lozano-Perez, “Spatial planning: a configuration space approach,” IEEE Transactions on Computers, vol. C-32, no.. 2, pp. 108–120, Feb. 1983.

J. Barraquand and J.-C. Latombe, “Robot motion planning: a distributed representation approach,” The International Journal of Robotics Research, vol. 10, no. 6, pp. 628–649, Dec. 1991.

Y. Fei, D. Fuqiang, and Z. Xifang, “Collision-free motion planning of dual-arm reconfigurable robots,” Robotics and Computer-Integrated Manufacturing, vol. 20, no. 4, pp. 351–357, 2004.

J. Canny, The Complexity of Robot Motion Planning, MIT Press, 1988.

X. Cheng, “On-line collision-free path planning for service and assembly tasks by a two-arm robot,” Proc. of the IEEE International Conference on Robotics and Automation, pp. 1523–1528, May 1995.

A. Montano and R. Suarez, “An on-line coordination algorithm for multi-robot systems,” Proc. of the IEEE 18th Conference on Emerging Technologies & Factory Automation (ETFA), pp. 1–7, 2013.

P. A. O’Donnell and T. Lozano-Perez, “Deadlock-free and collision-free coordination of two robot manipulators,” Proc. of the IEEE International Conference on Robotics and Automation, pp. 484–489, May 1989.

D.-H. Lee, D.-H. Kim, J. Y. Lee, and C.-S, Han, “Collisionfree coordination of two dual-arm robots with assembly precedence constraint,” Proc. of the International Conference on Control, Automation and Systems, pp. 515–520, Oct. 2014.

M. Gharbi, J. Cortes, and T. Simeon, “A sampling-based path planner for dual-arm manipulation,” Proc. of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, pp. 383–388, July 2008.

L. Biagiotti and C. Mechiorri, Trajectory Planning for Automatic Machines and Robots, Springer, pp. 62–76, 2008.

H. J. Yoon and S. Y. Chung, “Task sequence optimization for 6-DOF manipulator in press forming process,” Journal of the Korea Academia-Industrial Cooperation Society, vol. 18, no. 2, pp. 704–710, 2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seok Chang Ryu under the direction of Editor Won-jong Kim. This work was supported by research grants from Daegu Catholic University in 2017.

Hyun Joong Yoon received his B.S. degree in Mechanical Engineering from Yonsei University, Seoul, Korea, in 1997, and M.S. and Ph.D. degrees in mechanical engineering from Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Korea in 1999 and 2004, respectively. From 2004 to 2005, he was a postdoctoral fellow at the Integrated Manufacturing Technologies Institute of the National Research Council Canada, London, ON, Canada. He was a senior researcher at the Mechatronics and Manufacturing Technology Research Center, Samsung Electronics Company, Ltd., Suwon, Gyeonggi-Do, Republic of Korea from 2005 to 2008. He has been on the faculty of the School of Mechanical and Automotive Engineering of the Catholic University of Daegu, Korea since 2008, where he is currently an associate professor. His current research interests include modeling, optimization, and simulation of automated manufacturing systems.

Seong Youb Chung received his B.S. degree in Mechanical Engineering from Yonsei University, Seoul, Republic of Korea, in 1994, and his M.S. and Ph.D. degrees in Mechanical Engineering from Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Republic of Korea, in 1996 and 2005, respectively. From 2005 to 2007, he was a senior research engineer at the Institute of Industrial Technology, Samsung Heavy Industries Co., Ltd, Daejeon, Republic of Korea. He has been on the faculty of the Department of Mechanical Engineering of the Korea National University of Transportation, Chungju, Republic of Korea since 2007, where he is currently a professor. His research interests include human–robot interfaces, multiple robots, and machine vision.

Myun Joong Hwang received his B.S., M.S., and Ph.D. degrees in Mechanical Engineering from the Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Republic of Korea, in 2001, 2003, and 2007, respectively. He is an assistant professor in the Department of Mechanical Engineering, Korea National University of Transportation, Chungju, Republic of Korea since 2015. He was a research associate at the Mechanical Engineering Research Institute, KAIST in 2007. From 2008 to 2009, he was a research associate in the Department of Electrical Engineering and Computer Science, Case Western Reserve University, Cleveland, OH, USA. He was a senior research engineer at the Manufacturing Technology Center, Samsung Electronics Company, Ltd., Suwon, Republic of Korea from 2010 to 2013. He was an assistant professor in the School of Mechanical and Automotive Engineering, Halla University, Wonju, Republic of Korea from 2013 to 2015. His research interests include motion planning and control of manipulator, cooperation of multi-robots, and medical robotics.

Rights and permissions

About this article

Cite this article

Yoon, H.J., Chung, S.Y. & Hwang, M.J. Shadow Space Modeling and Task Planning for Collision-free Cooperation of Dual Manipulators for Planar Task. Int. J. Control Autom. Syst. 17, 995–1006 (2019). https://doi.org/10.1007/s12555-018-0236-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12555-018-0236-1