Abstract

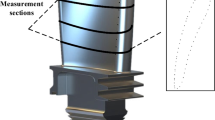

The manufacture of large-scale products such as aircraft and wind turbines needs detailed inspection to ensure the required dimensional tolerances are met. A coherent laser radar with an assisting mirror was used in this research to inspect a half-size wind turbine blade. This paper investigates the optimal distribution of inspection points that would produce the most accurate B-Spline fitting to the CAD model surfaces and so shorten the inspection and analysis process without compromising on accuracy. Even though the optimal solution was found to be points with 100 mm spacing on a moderate surface gradient and with 20–25 mm spacing on a more severe surface gradient, the findings suggest the employment of a non-uniform distribution would produce a more accurate fitting. This paper also explores data alignment by Degree of Freedom constraints with a triple B-Spline and investigates whether denser data points would improve the transformation. The optimal solution was found to be constraining movement in Z, Rx and Ry. Therefore, to achieve better transformation, surfaces were treated based on their gradient. This resulted in a constraint in X, Y and Z, and Ry for a moderate gradient and Y, Z and Rz for a more severe gradient. The optimal number of inspection points for fitting a B-Spline on a half-size blade was found to be 18 points for the front section with 100 mm spacing, 15 points for the back section with 100 mm spacing, and between 14 and 18 points with 20–25 mm spacing on the base section.

Similar content being viewed by others

References

Puttock, M. (1978). Large-scale metrology. CIRP Annals—Manufacturing Technology, 21(3), 351–356.

Estler, W., Edmundon, K., Peggs, G., & Parker, D. H. (2002). Large-scale metrology—An update. CIRP Annals—Manufacturing Technology, 51(2), 587–609.

Peggs, G., Maropoulos, P., Hughes, E., Forbes, A., Robson, S., Ziebart, M., et al. (2009). Recent developments in large-scale dimensional metrology. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 223(6), 571–595.

Franceschini, F., Galetto, M., Maisano, D., & Mastrogiacomo, L. (2014). Large-scale dimensional metrology (LSDM): From tapes and theodolites to multi-sensor systems. International Journal of Precision Engineering and Manufacturing, 15(8), 1739–1758.

Schmitt, R. H., Peterek, M., Morse, E., Knapp, W., Galetto, M., Härtig, F., et al. (2016). Advances in large-scale metrology—Review and future trends. CIRP Annals—Manufacturing Technology, 65, 643–665.

Wang, Q., Zissler, N., & Holden, R. (2013). Evaluate error sources and uncertainty in large scale measurement systems. Robotics and Computer-Integrated Manufacturing, 29, 1–11.

Weckenmann, A., Jiang, X., Sommer, K.-D., Neuschaefer-Rube, U., Seewig, J., Shaw, L., et al. (2009). Multisensor data fusion in dimensional metrology. CIRP Annals—Manufacturing Technology, 58, 701–721.

Galetto, M., & Pralio, B. (2010). Optimal sensor positioning for large scale metrology applications. Precision Engineering, 34, 563–577.

Ramasamy, S. K., & Raja, J. (2013). Performance evaluation of multi-scale data fusion methods for surface metrology domain. Journal of Manufacturing Systems, 32, 514–522.

Galetto, M., Mastrogiacomo, L., Maisano, D., & Franceschini, F. (2015). Cooperative fusion of distributed multi-sensor LVM (large volume metrology) systems. CIRP Annals—Manufacturing Technology, 64, 483–486.

Maisano, D., & Mastrogiacomo, L. (2016). A new methodology to design multi-sensor networks for distributed large-volume metrology systems based on triangulation. Precision Engineering, 43, 105–118.

Franceschini, F., Galetto, M., Maisano, D., & Mastrogiacomo, L. (2016). Combing multiple large volume metrology systems: Competitive versus cooperative data fusion. Precision Engineering, 43, 514–524.

Galetto, M., Mastrogiacomo, L., Maisano, D., & Fraanceschini, F. (2016). Uncertainty evaluation of distributed large-scale-metrology systems by a Monte Carlo approach. CIRP Annals—Manufacturing Technology, 65, 491–494.

Jang, Y.-S., & Kim, S.-W. (2017). Compensation of the refractive index of air in laser interferometer for distance measurement: A review. International Journal of Precision Engineering and Manufacturing, 18(12), 1881–1890.

Wang, J., Pagani, L., Leach, R. K., Zeng, W. H., Colosimo, B. M., & Zhou, P. L. (2017). Study of weighted fusion methods for the measurement of surface geometry. Precision Engineering, 47, 111–121.

Ren, M. J., Sun, L. J., Liu, M. Y., Cheung, C. F., Yin, Y. H., & Cao, Y. L. (2017). A weighted least square based data fusion method for precision measurement of freeform surfaces. Precision Engineering, 48, 144–151.

Schwenke, H., Neuschaefer-Rube, U., Pfeifer, T., & Kunzmann, H. (2002). Optical methods for dimensional metrology in production engineering. CIRP Annals—Manufacturing Technology, 51(2), 685–699.

Savio, E., De Chiffre, L., & Schmitt, R. (2007). Metrology of freeform shaped parts. CIRP Annals—Manufacturing Technology, 56(2), 810–835.

Talbot, J., Wang, Q., Brady, N., & Holden, R. (2016). Offshore wind turbine blades measurement using coherent laser radar. Measurement, 79, 53–65.

Summers, A., Wang, Q., Brady, N., & Holden, R. (2016). Investigating the measurement of offshore wind turbine blades using coherent laser radar. Robotics and Computer-Integrated Manufacturing, 41, 43–52.

Auger, D., Wang, Q., Trevelyan, J., Huang, S. L., & Zhao, W. (2018). Investigating the quality inspection process of offshore wind turbine blades using B-spline surfaces. Measurement, 115, 162–172.

Slotwinski, A. R., Goodwin, F. E., & Simonson, D. L. (1989). Utilizing GaalAs laser diodes as a source for frequency modulated continuous wave (FMCW) coherent laser radar. In Proc. SPIE, laser diode technology and applications (Vol. 1043, pp. 245–251).

Nikon Metrology. (2014). Laser radar MV330/350—For automated, non-contact large scale metrology. Nikon Metrology, 2014. http://www.nikonmetrology.com/en_EU/Products/Large-Volume-Applications/Laser-Radar/MV330-MV350-Laser-Radar. Accessed July 2018.

New River Kinematics. (2014). Spatial analyzer. New River Kinematics, 2014. http://www.kinematics.com/spatialanalyzer/. Accessed July 2018.

de Boor, C. (1972). On calculating with B-splines. Journal of Approximation Theory, 6(1), 50–62.

Tai, C., Hu, S., & Huang, Q. (2003). Approximate merging of B-spline curves via knot adjustment and constrained optimization. Computer-Aided Design, 35, 893–899.

Chen, X., Ma, W., Xu, G., & Paul, J.-C. (2010). Computing the Hausdorff distance between two B-spline curves. Computer-Aided Design, 42(12), 1197–1206.

Yang, Y., Cao, S., Yong, J., Zhang, H., Paul, J.-C. J., Sun, J., et al. (2008). Approximate computation of curves on B-spline surfaces. Computer-Aided Design, 20(2), 223–234.

Yang, H., Wang, W., & Sun, J. (2004). Control point adjustment for B-spline curve approximation. Computer-Aided Design, 36, 639–652.

Li, H., & Kong, X. (2013). A novel modeling approach in blade shape design. Journal of Convergence Information Technology, 8(8), 1013–1020.

Acknowledgements

The authors would like to acknowledge the financial support received from Royal Academy of Engineering Newton Research Collaboration Programme (NRCP/1415/91) and Royal Society—China Natural Science Foundation International Exchange Award (IE150600).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chan, C.H.L., Wang, Q., Holden, R. et al. Optimal Number of Control Points for Fitting B-Splines in Wind Turbine Blade Measurement. Int. J. Precis. Eng. Manuf. 20, 1507–1517 (2019). https://doi.org/10.1007/s12541-019-00173-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00173-2