Abstract

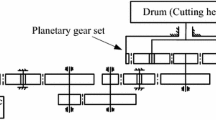

With the rapid development of processing technology, the demand for precision, durability and NVH performance of processing machinery has also increased. This paper presents an optimally designed gear train composed of a set each of spiral bevel gears and spur gears to serve as a high precision rotating unit for processing machinery. The safety of each component used in the rotating unit gear train was verified using the geometry method and empirical formulae. The load contact pattern and PPTE value, which is an important indicator of the gear whine characteristic, were optimized using micro geometry modifications. In addition, the transfer efficiency of the entire gear train was determined and a novel dynamic analysis based on the comparison of the dynamic transmission error and the modal flexibility was performed to verify the correctness of the geometry design.

Similar content being viewed by others

Abbreviations

- \(b_{V}\) :

-

Face width calculated for the flank, drive or coast side

- \(F_{vmt}\) :

-

Nominal tangential force

- \(F_{\text{n}}\) :

-

Nominal normal force of the virtual cylindrical gear at mean point P

- \(K_{A}\) :

-

Application factor

- \(K_{V}\) :

-

Dynamic factor

- \(K_{{{\text{H}}\upalpha}}\) :

-

Transverse load factor (contact stress)

- \(K_{{{\text{H}}\upbeta}}\) :

-

Face load factor (contact stress)

- \(K_{{{\text{F}}\upalpha}}\) :

-

Transverse load factor (root stress)

- \(K_{{{\text{F}}\upbeta}}\) :

-

Face load factor (root stress)

- \(l_{\text{bm}}\) :

-

Length of contact line in the middle of the zone

- \(S_{H - B1}\) :

-

Safety factor for the contact stress

- \(S_{F - B1}\) :

-

Safety factor for the tooth bending strength

- \(Y_{\text{Fa}}\) :

-

Tooth form factor

- \(Y_{Sa}\) :

-

Stress correction factor

- \(Y_{\varepsilon }\) :

-

Contact ratio factor

- \(Y_{BS}\) :

-

Bevel spiral angle factor

- \(Y_{LS}\) :

-

Load sharing factor (load distribution)

- \(Y_{\text{NT}}\) :

-

Life factor (root stress)

- \(Y_{{\updelta,\;{\text{relT}} - {\text{B}}1}}\) :

-

Relative notch sensitivity factor

- \(Y_{{{\text{R}},\;{\text{relT}} - {\text{B}}1}}\) :

-

Relative surface condition factor

- \(Y_{\text{X}}\) :

-

Size factor (root stress)

- \(Z_{{{\text{M}} - {\text{B}}}}\) :

-

Mid-zone factor

- \(Z_{\text{LS}}\) :

-

Load sharing factor

- \(Z_{E}\) :

-

Elasticity factor

- \(Z_{\text{K}}\) :

-

Bevel gear factor

- \(Z_{\text{NT}}\) :

-

Life factor (contact stress)

- \(Z_{X}\) :

-

Size effect factor (contact stress)

- \(Z_{L} ,Z_{V} ,Z_{R}\) :

-

Lubricant factor

- \(Z_{W}\) :

-

Work hardening factor

- \(Z_{Hyp}\) :

-

Hypoid factor

- \(\rho_{rel}\) :

-

Radius of relative curvature vertical to contact line

- \(\upsigma_{\text{FE}}\) :

-

Allowable stress number (root)

- \(\upsigma_{\text{H,lim}}\) :

-

Allowable stress number (contact), MPa

References

Adair, K., Kapoor, S. G., & DeVor, R. E. (2011). Development of a unique topology for a hard-turning micro-scale machine tool. Journal of Manufacturing Processes, 13, 75–84.

Kobayashi, Y., & Shirai, K. (2008). Multi-axis milling for microtexturing. International Journal of Precision Engineering and Manufacturing, 9(1), 34–38.

Syahputra, H. P., & Ko, T. J. (2013). Application of image processing to micro-milling process for surface texturing. International Journal of Precision Engineering and Manufacturing, 14(9), 1507–1512.

Lee, W. B., Cheung, C. F., Chiu, W. M., & Leung, T. P. (2000). An investigation of residual form error compensation in the ultra precision machining of aspheric surfaces. Journal of Materials Processing Technology, 99, 129–134.

Fan, W., Lee, C. H., & Chen, J. H. (2016). Real-time repairable interpolation scheme for CNC tool path processing. International Journal of Precision Engineering and Manufacturing, 17(12), 1673–1684.

Chen, S. T., Chang, K. E., Huang, W. P., Yang, H. Y., & Lee, X. M. (2012). Development of a cost-effective high-precision bench machine tool for multi-level micro aspheric lighting lens mold machining. International Journal of Precision Engineering and Manufacturing, 13(12), 2225–2231.

Qin, Z., Wu, Y. T., & Lyu, S. K. (2018). A review of recent advances in design optimization of gearbox. International Journal of Precision Engineering and Manufacturing, 19(11), 1753–1762.

Zhang, Q., Kang, J., Li, Q., & Lyu, S. K. (2012). The calculation and experiment for measurements over pins of the external helical gears with an odd number of teeth. International Journal of Precision Engineering and Manufacturing, 13(12), 2203–2208.

Lee, G. U., Sul, S. K., & Kim, J. W. (2015). Energy-saving method of parallel mechanism by redundant actuation. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(4), 345–351.

Zhang, Q., Kang, J., Dong, W., & Lyu, S. (2012). A study on tooth modification and radiation noise of a manual transaxle. International Journal of Precision Engineering and Manufacturing, 13(6), 1013–1020.

Wei, J., Lv, C., Sun, W., Li, X., & Wang, Y. (2013). A study on optimum design method of gear transmission system for wind turbine. International Journal of Precision Engineering and Manufacturing, 14(5), 767–778.

Miler, D., Loncar, A., Žeželj, D., & Domitran, Z. (2017). Influence of profile shift on the spur gear pair optimization. Mechanism and Machine Theory, 117, 189–197.

He, H. B., Li, H. Y., Lyu, S. K., Tak, S. H., Moon, S. M., & Zhang, Q. (2009). Optimal design of a tilling machine reduction gearbox using Matlab. International Journal of Precision Engineering and Manufacturing, 10(2), 63–66.

Qin, Z., Son, H. I., & Lyu, S. K. (2018). Design of anti-vibration mounting for 140A class alternator for vehicles. Journal of Mechanical Science and Technology, 32(11), 5233–5239.

Kim, S. K., Sung, G. W., Gwon, J. G., & Kim, J. H. (2016). Controlled phase separation in flexible polyurethane foams with diethanolamine cross-linker for improved sound absorption efficiency. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(4), 367–373.

Jin, J. W., Kang, K. W., & Kim, J. H. (2018). Development of durability test procedure of vibration-based energy harvester in railway vehicle. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(4), 353–358.

Acknowledgements

This study was supported by the Basic Science Research Program through the NRF of Korea (NRF) Funded by the MEST (NRF-2016R1D1A1A09920105).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, Z., Wu, YT., Eizad, A. et al. A Study on Simulation Based Validation of Optimized Design of High Precision Rotating Unit for Processing Machinery. Int. J. Precis. Eng. Manuf. 20, 1601–1609 (2019). https://doi.org/10.1007/s12541-019-00155-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00155-4