Abstract

The influence of working temperature and number of passes on the mechanical properties of aluminium alloy, AA 5083, processed by cyclic expansion and extrusion (CEE) is discussed. The specimens were processed up-to 10 CEE passes at 200 °C, 300 °C and 400 °C. The average grain size of the starting annealed material was 84.5 ± 6.8 μm, with 39.4% being of the high-angle grain boundaries (HAGBs) type. After 8 CEE passes at 200 °C the material had an average grain size of 3.3 ± 0.6 μm and 41.3% of the grain boundaries were of the high-angle type (HAGBs). The combined effect of an increase in dislocation density and reduction in grain size as a result of CEE processing contributed to an increase in hardness and strength of the alloy. At 200 °C, the specimen exhibited uniform hardness values with a maximum improvement of 104% after 8 passes and the ultimate tensile strength had also increased by 64% compared with the unprocessed condition. However, the mechanical properties decreased in the specimens that were processed at the higher temperatures of 300 °C and 400 °C.

Graphic abstract

Similar content being viewed by others

References

J.M. García-Infanta, A.P. Zhilyaev, A. Sharafutdinov, O.A. Ruano, F. Carreño, An evidence of high strain rate superplasticity at intermediate homologous temperatures in an Al–Zn–Mg–Cu alloy processed by high-pressure torsion. J. Alloys Comp. 473, 163–166 (2009)

R.Z. Valiev, T.G. Langdon, Developments in the use of ECAP processing for grain refinement. Rev. Adv. Mater. Sci. 13, 15–26 (2006)

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45, 103–189 (2000)

A.P. Zhilyaev, T.G. Langdon, Using high-pressure torsion for metal processing: fundamentals and applications. Prog. Mater. Sci. 53, 893–979 (2008)

Z. Horita, T. Fujinami, M. Nemoto, T.G. Langdon, Equal-channel angular pressing of commercial aluminum alloys: grain refinement, thermal stability and tensile properties. Metall. Mater. Trans. A 31, 691–701 (2000)

S.H. Seyed Ebrahimi, K. Dehghani, J. Aghazadeh, M.B. Ghasemian, S. Zangeneh, Investigation on microstructure and mechanical properties of Al/Al–Zn–Mg–Cu laminated composite fabricated by accumulative roll bonding (ARB) process. Mater. Sci. Eng. A 718, 311–320 (2018)

M. Richert, J. Richert, J. Zasadziński, S. Hawryłkiewicz, J. Długopolski, Effect of large deformations on the microstructure of aluminium alloys. Mater. Chem. Phys. 81, 528–530 (2003)

N. Thangapandian, S. Balasivanandha Prabu, K.A. Padmanabhan, Effects of die profile on grain refinement in Al–Mg alloy processed by repetitive corrugation and straightening. Mater. Sci. Eng. A 649, 229–238 (2016)

H. Lianxi, L. Yuping, W. Erde, Y. Yang, Ultrafine grained structure and mechanical properties of a LY12 Al alloy prepared by repetitive upsetting-extrusion. Mater. Sci. Eng. A 422, 327–332 (2006)

M.R. Jandaghi, H. Pouraliakbar, M.K.G. Shiran, G. Khalaj, M. Shirazi, On the effect of non-isothermal annealing and multi-directional forging on the microstructural evolutions and correlated mechanical and electrical characteristics of hot-deformed Al–Mg alloy. Mater. Sci. Eng. A 657, 431–440 (2016)

D.M. Fouad, A. Moataz, W.H. El-Garaihy, H.G. Salem, Numerical and experimental analysis of multi-channel spiral twist extrusion processing of AA5083. Mater. Sci. Eng. A 764, 138216 (2019)

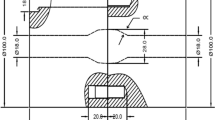

N. Pardis, B. Talebanpour, R. Ebrahimi, S. Zomorodian, Cyclic expansion-extrusion (CEE): A modified counterpart of cyclic extrusion-compression (CEC). Mater. Sci. Eng. A 528, 7537–7540 (2011)

K.A. Padmanabhan, S. Balasivanandha Prabu, On the conflicts in the experimental results concerning the mechanical properties of ultra-fine grained and nanostructured materials: effects of processing routes and experimental conditions. Mater. Sci. Forum 683, 3–54 (2011)

J.J. Rino, S. Balasivanandha Prabu, K.A. Padmanabhan, On the influence of repetitive corrugation and straightening on the microstructure and mechanical properties of AA 8090 Al–Li alloy. Arch. Civ. Mech. Eng. 18, 280–290 (2018)

N. Thangapandian, S. Balasivanandha Prabu, K.A. Padmanabhan, Effect of temperature and velocity of pressing on grain refinement in AA5083 aluminum alloy during repetitive corrugation and straightening process. Metall. Mater. Trans. A 47, 6374–6383 (2016)

J.J. Rino, I. Jayaram Krishnan, S. Balasivanandha Prabu, K.A. Padmanabhan, Influence of velocity of pressing in RCS processed AA8090 Al–Li alloy. Mater. Charact. 140, 55–63 (2018)

N. Hansen, Hall–Petch relation and boundary strengthening. Scr. Mater. 51, 801–806 (2004)

N.Q. Chinh, J. Gubicza, T. Czeppe, J. Lendvai, C. Xu, R.Z. Valiev, T.G. Langdon, Developing a strategy for the processing of age-hardenable alloys by ECAP at room temperature. Mater. Sci. Eng. A 516, 248–252 (2009)

N. Fakhar, F. Fereshteh-Saniee, R. Mahmudi, Significant improvements in mechanical properties of AA5083 aluminum alloy using dual equal channel lateral extrusion. Trans. Nonferrous Met. Soc. China 26, 3081–3090 (2016)

S. Najafi, A.R. Eivani, M. Samaee, H.R. Jafarian, J. Zhou, A comprehensive investigation of the strengthening effects of dislocations, texture and low and high angle grain boundaries in ultrafine grained AA6063 aluminum alloy. Mater. Charact. 136, 60–68 (2018)

I. Mazurina, T. Sakai, H. Miura, O. Sitdikov, R. Kaibyshev, Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. A 486, 662–671 (2008)

A. Goloborodko, O. Sitdikov, R. Kaibyshev, H. Miura, T. Sakai, Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP. Mater. Sci. Eng. A 381, 121–128 (2004)

V. Babu, S. Balasivanandha Prabu, K.A. Padmanabhan, Microstructure homogeneity in AA6063 alloy processed by cyclic expansion extrusion. Defect Diffusion Forum 385, 223–227 (2018)

K.R. Cardoso, M.A. Munoz-Morris, K.V. León, D.G. Morris, Room and high temperature ECAP processing of Al–10% Si alloy. Mater. Sci. Eng. A 587, 387–396 (2013)

S. Bathul, R.C. Anandani, A. Dhar, A.K. Srivastava, Microstructural features and mechanical properties of Al 5083/SiCp metal matrix nanocomposites produced by high energy ball milling and spark plasma sintering. Mater. Sci. Eng. A 545, 97–102 (2012)

S.Y. Chang, B.D. Ahn, S.K. Hong, S. Kamado, Y. Kojima, D.H. Shin, Tensile deformation characteristics of a nano-structured 5083 Al alloy. J. Alloys Compd. 386, 197–201 (2005)

B.B. Straumal, B. Baretzky, A.A. Mazilkin, F. Phillipp, O.A. Kogtenkova, M.N. Volkov, R.Z. Valiev, Formation of nanograined structure and decomposition of supersaturated solid solution during high pressure torsion of Al–Zn and Al–Mg alloys. Acta Mater. 52, 4469–4478 (2004)

T.B. Massalski, et al. (eds.), Binary Alloy Phase Diagrams (ASM International, Materials Park, 1993), p. 3534

Y. Iwahashi, Z. Horita, M. Nemoto, T.G. Langdon, The process of grain refinement in equal-channel angular pressing. Acta Mater. 46, 3317–3331 (1998)

T. Morishige, T. Hirata, T. Uesugi, Y. Takigawa, M. Tsujikawa, K. Higashi, Effect of Mg content on the minimum grain size of Al–Mg alloys obtained by friction stir processing. Scr. Mater. 64, 355–358 (2011)

H. Huang, J. Zhang, Microstructure and mechanical properties of AZ31 magnesium alloy processed by multi-directional forging at different temperatures. Mater. Sci. Eng. A 674, 52–58 (2016)

F. Liu, H. Yuan, J. Yin, J.T. Wang, Influence of stacking fault energy and temperature on microstructures and mechanical properties of fcc pure metals processed by equal-channel angular pressing. Mater. Sci. Eng. A 662, 578–587 (2016)

P. Rodriguez-Calvillo, J.M. Cabrera, Microstructure and mechanical properties of a commercially pure Ti processed by warm equal channel angular pressing. Mater. Sci. Eng. A 625, 311–320 (2015)

D. Singh, R. Jayaganthan, P. Nageswara Rao, A. Kumar, D. Venketeswarlu, Effect of initial grain size on microstructure and mechanical behavior of cryorolled AA 5083. Mater. Today Proc. 4, 7609–7617 (2017)

G. Morris David, I. Gutierrez-Urrutia, M.A. Munoz-Morris, Analysis of strengthening mechanisms in a severely-plastically-deformed Al–Mg–Si alloy with submicron grain size. J. Mater. Sci. 42, 1439–1443 (2007)

A. Chidambaram, S. Balasivanandha Prabu, K.A. Padmanabhan, Microstructure and mechanical properties of AA6061–5wt.% TiB2 in-situ metal matrix composite subjected to equal channel angular pressing. Mater. Sci. Eng. A 759, 762–769 (2019)

O. Sitdikov, E. Avtokratova, T. Sakai, K. Tsuzaki, Ultrafine-grain structure formation in an Al–Mg–Sc alloy during warm ECAP. Metall. Mater. Trans. A 44, 1087–1100 (2013)

W. Guo, Q.D. Wang, B. Ye, M.P. Liu, T. Peng, X.T. Liu, H. Zhou, Enhanced microstructure homogeneity and mechanical properties of AZ31 magnesium alloy by repetitive upsetting. Mater. Sci. Eng. A 540, 115–122 (2012)

A.L.D.M. Costa, A.C.D.C. Reis, L. Kestens, M.S. Andrade, Ultra grain refinement and hardening of IF-steel during accumulative roll-bonding. Mater. Sci. Eng. A 406, 279–285 (2005)

K.T. Park, H.J. Kwon, W.J. Kim, Y.S. Kim, Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process. Mater. Sci. Eng. A 316(1–2), 145–152 (2001)

F. Dalla Torre, R. Lapovok, J. Sandlin, P.F. Thomson, C.H.J. Davies, E.V. Pereloma, Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 52, 4819–4832 (2004)

S.N. Alhajeri, N. Gao, T.G. Langdon, Hardness homogeneity on longitudinal and transverse sections of an aluminum alloy processed by ECAP. Mater. Sci. Eng. A 528, 3833–3840 (2011)

V. Aferdita, M. Cabibbo, T.G. Langdon, A characterization of microstructure and microhardness on longitudinal planes of an Al–Mg–Si alloy processed by ECAP. Mater. Charact. 84, 126–133 (2013)

S. Cheng, Y.H. Zhao, Y.T. Zhu, E. Ma, Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 55, 5822–5832 (2007)

Y.H. Zhao, X.Z. Liao, S. Cheng, E. Ma, Y.T. Zhu, Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 18, 2280 (2006)

S. Spriano, R. Doglione, Marcello Baricco, Texture, hardening and mechanical anisotropy in AA 8090-T851 plate. Mater. Sci. Eng. A 257, 134–138 (1998)

H. Pirgazi, A. Akbarzadeh, R. Petrov, L. Kestens, Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater. Sci. Eng. A 497, 132–138 (2008)

Y.Z. Guo, Y.L. Li, Z. Pan, F.H. Zhou, Q. Wei, A numerical study of microstructure effect on adiabatic shear instability: application to nanostructured/ultrafine grained materials. Mech. Mater. 42, 1020–1029 (2010)

A. Alam, D.D. Johnson, Structural properties and relative stability of (meta) stable ordered, partially ordered, and disordered Al–Li alloy phases. Phys. Rev. B Condens. Matter Mater. Phys. 85, 144202 (2012)

R. Wu, Z. Qu, M. Zhang, Effects of the addition of Y in Mg–8Li–(1, 3) Al alloy. Mater. Sci. Eng. A 516, 96–99 (2009)

T. Wang, H. Zheng, R. Wu, J. Yang, X. Ma, M. Zhang, Preparation of fine-grained and high-strength Mg–8Li–3Al–1Zn alloy by accumulative roll bonding. Adv. Eng. Mater. 18, 304–311 (2016)

R. Jamaati, M.R. Toroghinejad, High-strength and highly-uniform composite produced by anodizing and accumulative roll bonding processes. Mater. Des. 31, 4816–4822 (2010)

H.Y. Wu, G.Z. Zhou, Plastic anisotropy and strain-hardening behavior of Mg–6% Li–1% Zn alloy thin sheet at elevated temperatures. J. Mater. Sci. 44, 6182–6186 (2009)

G. Nussbaum, P. Saintfort, G. Regazzoni, H. Gjestland, Strengthening mechanisms in the rapidly solidified AZ 91 magnesium alloy. Scr. Mater. 23, 1079–1084 (1989)

N. Tsuji, Y. Ito, Y. Saito, Y. Minamino, Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 47, 893–899 (2002)

M. Shaarbaf, M.R. Toroghinejad, Nano-grained copper strip produced by accumulative roll bonding process. Mater. Sci. Eng. A 473, 28–33 (2008)

N. Thangapandian, S. Balasivanandha Prabu, Effect of combined repetitive corrugation and straightening and rolling on the microstructure and mechanical properties of pure aluminum. Metallogr. Microstruct. Anal. 6, 481–488 (2017)

D.H. Kang, T.W. Kim, Mechanical behavior and microstructural evolution of commercially pure titanium in enhanced multipass equal channel angular pressing and cold extrusion. Mater. Des. 31, 54–60 (2010)

M.R. Rezaei, M.R. Toroghinejad, F. Ashrafizadeh, Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy. J. Mater. Proc. Technol. 211, 1184–1190 (2011)

H. Sheikh, E. Paimozd, S.M. Hashemi, Work hardening of Duratherm 600 cobalt superalloy using repetitive corrugation and straightening process. Russ. J. Non-Ferrous Met. 51, 59–61 (2010)

R. Armstrong, I. Godd, R.M. Douthwaite, N.J. Petch, The plastic deformation of polycrystalline aggregates. Philos. Mag. 7, 45–58 (1962)

D. Singh, P.N. Rao, R. Jayaganthan, Effect of deformation temperature on mechanical properties of ultrafine grained Al–Mg alloys processedby rolling. Mater. Des. 50, 646–655 (2013)

V.S. Sarma, K. Sivaprasad, D. Sturm, M. Heilmaier, Microstructure and mechanical properties of ultra fine grained Cu–Zn and Cu–Al alloys produced by cryorolling and annealing. Mater. Sci. Eng. A 489, 253–258 (2008)

J. Gubicza, N.Q. Chinh, Z. Horita, T.G. Langdon, Effect of Mg addition on microstructure and mechanical properties of aluminum. Mater. Sci. Eng. A 387, 55–59 (2004)

G. Faraji, M.M. Mashhadi, A.R. Bushroa, A. Babaei, TEM analysis and determination of dislocation densities in nanostructured copper tube produced via parallel tubular channel angular pressing process. Mater. Sci. Eng. A 563, 193–198 (2013)

W.J. Kim, S.I. Hong, Y.H. Kim, Enhancement of the strain hardening ability in ultrafine grained Mg alloys with high strength. Scr. Mater. 67, 689–692 (2012)

Acknowledgements

The authors thank Prof. Indradev Samajdar, IIT Bombay, for extending the use of the EBSD facility. The authors also acknowledge the help of PSG College of Technology, Coimbatore, India for making available the HRTEM facility for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babu, V., Shanmugavel, B.P. & Padmanabhan, K.A. On the Influence of Temperature and Number of Passes on the Mechanical Properties of an Al–Mg Alloy Processed by Cyclic Expansion Extrusion. Met. Mater. Int. 27, 2919–2932 (2021). https://doi.org/10.1007/s12540-020-00781-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00781-y