Abstract

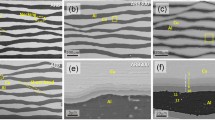

The Al/hard chrome/Al laminate with cracked interlayer was processed by single-pass rolling and accumulative roll bonding (ARB). A micro-cracked hard chrome with the thickness range of 5–15 µm was deposited on the Al layer by the electroplating process. The micro-cracked hard chrome layer was considered as a model material to investigate the deformation processing of the metal laminate with a discontinuous interlayer. The layered composite with discontinuous interlayer was modeled by finite element analysis. Three configurations of discontinuities, including the longitudinal, transverse, and rectangular pattern, were considered in the interlayer. In agreement with the experiments, the simulation results showed that during the roll bonding process, the discontinuities that are oriented transversely spread in the rolling direction while those that are located longitudinally slightly expand in the transverse direction. The peeling test after the single roll bonding revealed that the bond strength of the Al/Cr composite with cracked interlayer increased with increasing the thickness reduction and decreasing the hard chrome layer. The hard chrome layer was gradually fragmented during the ARB process and was distributed in the Al matrix.

Graphic Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

References

M. Rahdari, M. Reihanian, S.M.L. Baghal, Mater. Sci. Eng. A 738, 98–110 (2018)

J.-M. Lee, B.-R. Lee, S.-B. Kang, Mater. Sci. Eng. A 406, 95–101 (2005)

L. Su, C. Lu, A.K. Tieu, G. Deng, X. Sun, Mater. Sci. Eng. A 559, 345–351 (2013)

F. Daneshvar, M. Reihanian, K. Gheisari, Mater. Sci. Eng. B 206, 45–54 (2016)

S.V.A. Ana, M. Reihanian, B. Lotfi, Mater. Sci. Eng. A 647, 303–312 (2015)

V. Yousefi Mehr, M.R. Toroghinejad, A. Rezaeian, Mater. Sci. Eng. A 601, 40–47 (2014)

G.H. Min, J.M. Lee, S.B. Kang, H.W. Kim, Mater. Lett. 60, 3255–3259 (2006)

A. Mozaffari, H.D. Manesh, K. Janghorban, J. Alloys Compd. 489, 103–109 (2010)

A. Shabani, M.R. Toroghinejad, J. Mater. Eng. Perform. 24, 4746–4754 (2015)

M.M. Mahdavian, L. Ghalandari, M. Reihanian, Mater. Sci. Eng. A 579, 99–107 (2013)

L. Ghalandari, M.M. Mahdavian, M. Reihanian, Mater. Sci. Eng. A 593, 145–152 (2014)

L. Ghalandari, M.M. Mahdavian, M. Reihanian, M. Mahmoudiniya, Mater. Sci. Eng. A 661, 179–186 (2016)

K. Verstraete, H. Azzedine, A.-L. Helbert, F. Brisset, D. Bradai, T. Baudin, Adv. Eng. Mater. 20, 1700285 (2018)

Z. Chen, X. Wu, H. Hu, Q. Chen, Q. Liu, J. Mater. Eng. Perform. 23, 990–1001 (2014)

F. Nowicke, A. Zavaliangos, H.C. Rogers, Int. J. Mech. Sci. 48, 868–877 (2006)

H.S. Liu, B. Zhang, G.P. Zhang, Scripta Mater. 64, 13–16 (2011)

S.J. Zheng, J. Wang, J.S. Carpenter, W.M. Mook, P.O. Dickerson, N.A. Mara, I.J. Beyerlein, Acta Mater. 79, 282–291 (2014)

T. Öztürk, J. Mirmesdagh, T. Ediz, Mater. Sci. Eng. A 175, 125–129 (1994)

S.M. Arbo, I. Westermann, B. Holmedal, Key Eng. Mater. 767, 316–322 (2018)

M. Reihanian, M. Naseri, Mater. Des. 89, 1213–1222 (2016)

Y.-M. Hwang, H.-H. Hsu, H.-J. Lee, Int. J. Mach. Tools Manuf 36, 47–62 (1996)

S.L. Semiatin, H.R. Piehler, Metall. Trans. A 10, 97–107 (1979)

P.S. Steif, J. Appl. Metalwork. 4, 317–326 (1987)

F. Liang, H.-F. Tan, B. Zhang, G.-P. Zhang, Scripta Mater. 134, 28–32 (2017)

N. Junqua, J. Grilhé, Philos. Mag. Lett. 69, 61–70 (1994)

H. Yu, A.K. Tieu, C. Lu, X. Liu, A. Godbole, H. Li, C. Kong, Q. Qin, Sci. Rep. 4, 5017 (2014)

N.V. Govindaraj, J.G. Frydendahl, B. Holmedal, Mater. Des. 1980–2015 52, 905–915 (2013)

T. Imai, H. Utsunomiya, R. Matsumoto, Procedia Eng. 184, 306–312 (2017)

H. Utsunomiya, S. Maeda, T. Imai, R. Matsumoto, CIRP Ann. 67, 317–320 (2018)

Ö. Yazar, T. Ediz, T. Öztürk, Acta Mater. 53, 375–381 (2005)

G. Bolelli, V. Cannillo, L. Lusvarghi, S. Ricco, Surf. Coat. Technol. 200, 2995–3009 (2006)

N. Bay, Met. Constr. 18, 369–372 (1986)

W. Habila, H. Azzeddine, B. Mehdi, K. Tirsatine, T. Baudin, A.-L. Helbert, F. Brisset, S. Gautrot, M.-H. Mathon, D. Bradai, Mater. Charact. 147, 242–252 (2019)

V.C. Srivastava, T. Singh, S.G. Chowdhury, V. Jindal, J. Mater. Eng. Perform. 21, 1912–1918 (2012)

A. Mozaffari, M. Hosseini, H.D. Manesh, J. Alloys Compd. 509, 9938–9945 (2011)

K. Brunelli, L. Peruzzo, M. Dabalà, Mater. Chem. Phys. 149–150, 350–358 (2015)

M. Reihanian, R. Ebrahimi, N. Tsuji, M.M. Moshksar, Mater. Sci. Eng. A 473, 189–194 (2008)

M. Reihanian, R. Ebrahimi, M.M. Moshksar, D. Terada, N. Tsuji, Mater. Charact. 59, 1312–1323 (2008)

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, R.G. Hong, Scripta Mater. 39, 1221–1227 (1998)

Y. Saito, H. Utsunomiya, N. Tsuji, T. Sakai, Acta Mater. 47, 579–583 (1999)

R. Jamaati, M.R. Toroghinejad, A. Najafizadeh, Mater. Sci. Eng. A 527, 3857–3863 (2010)

A. Shabani, M.R. Toroghinejad, A. Shafyei, Mater. Sci. Eng. A 558, 386–393 (2012)

H. Chang, M.Y. Zheng, C. Xu, G.D. Fan, H.G. Brokmeier, K. Wu, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 543, 249–256 (2012)

R.N. Dehsorkhi, F. Qods, M. Tajally, Mater. Sci. Eng. A 530, 63–72 (2011)

M. Abbasi, S.A. Sajjadi, J. Mater. Eng. Perform. 27, 3508–3520 (2018)

M. Talebian, M. Alizadeh, Mater. Sci. Eng. A 590, 186–193 (2014)

Acknowledgements

Financial support provided by Shahid Chamran University of Ahvaz (Ahvaz, Iran) through the Grant No. SCU.EM98.375 is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fakher, S., Reihanian, M., Lari Baghal, S.M. et al. Role of Cracked Interlayer on Deformation Processing of Al/hard Chrome/Al Laminate. Met. Mater. Int. 27, 4780–4792 (2021). https://doi.org/10.1007/s12540-020-00768-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00768-9