Abstract

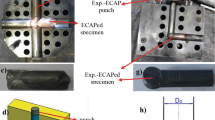

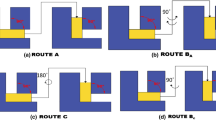

In this study, optimization of equal channel angular pressing (ECAP) parameters was aimed to improve the mechanical and microstructure properties of Al–Zn–Mg alloy using the Taguchi method with ANOVA analysis. Three different parameters (process temperature, processing route, and the number of passes) with three different levels were examined so L9 (33) orthogonal array was employed. The effects of these parameters on the microstructure properties of Al–Zn–Mg alloy were studied using X-ray diffractometer, optical microscopy, scanning electron microscopy, electron backscatter diffraction and transmission electron microscopy and mechanical properties were measured by Vickers micro-hardness experimental tests. Among the samples obtained, the sample that meets the desired hardness and grain size value was characterized. The results indicate that eight pass ECAP in route Bc at 100 °C is found as a more appropriate condition that meets the highest micro-hardness value and the lowest grain size value. Microstructural investigations showed that grain size was highly affected by the temperature, and is less affected by the number of passes and ECAP routes. The results showed that the increasing ECAP temperature leads to a decrease in the fraction of HABs, an increase in the grain size and an increase in the equiaxed of the grains.

Graphic Abstract

Similar content being viewed by others

Change history

12 February 2021

The Missed Graphic Abstract has been updated.

References

T.G. Langdon et al., Using equal channel angular pressing for refining grain size. Jom J. Miner. Metals Mater. Soc. 52(4), 30–33 (2000). https://doi.org/10.1007/s11837-000-0128-7

Z. Horita et al., Improvement of mechanical properties for Al alloys using equal-channel angular pressing. J. Mater. Process. Technol. 117(3), 288–292 (2001). https://doi.org/10.1016/S0924-0136(01)00783-X

Z. Horita, T. Fujinami, T.G. Langdon, The potential for scaling ECAP: effect of sample size on grain refinement and mechanical properties. Mater. Sci. Eng. Struct. Mater Prop. Microstruct. Process. 318(1–2), 34–41 (2001). https://doi.org/10.1016/S0921-5093(01)01339-9

R.Z. Valiev, T.G. Langdon, Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater Sci. 51(7), 881–981 (2006). https://doi.org/10.1016/j.pmatsci.2006.02.003

Y. Iwahashi et al., Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scripta Mater. 35(2), 143–146 (1996). https://doi.org/10.1016/1359-6462(96)00107-8

A.P. Zhilyaev, T.G. Langdon, Using high pressure torsion for metal processing: fundamentals and applications. Prog. Mater Sci. 53, 893–979 (2008). https://doi.org/10.1016/j.pmatsci.2008.03.002

S.L. Semiatin, A.A. Salem, M.J. Saran, Models for severe plastic deformation by equal-channel angular extrusion. JOM 56(10), 69–77 (2004). https://doi.org/10.1007/s11837-004-0296-y

P.N. Fagin et al., Failure modes during equal channel angular extrusion of aluminum alloy 2024. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 32(7), 1869–1871 (2001). https://doi.org/10.1007/s11661-001-0165-z

V.M. Segal, Equal channel angular extrusion: from macromechanics to structure formation. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 271(1–2), 322–333 (1999). https://doi.org/10.1016/S0921-5093(99)00248-8

N. Saito et al., Application of equal channel angular extrusion on strengthening of ferritic stainless steel. J. Mater. Sci. 36(13), 3229–3232 (2001). https://doi.org/10.1023/A:1017990420563

M.H. Shaeri et al., Effect of ECAP temperature on microstructure and mechanical properties of Al–Zn–Mg-Cu alloy. Prog. Nat. Sci. Mater. Int. 26(2), 182–191 (2016). https://doi.org/10.1016/j.pnsc.2016.03.003

M.A. Afifi et al., Effect of ECAP processing on microstructure evolution and dynamic compressive behavior at different temperatures in an Al–Zn–Mg alloy. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 684, 617–625 (2017). https://doi.org/10.1016/j.msea.2016.12.099

M.R. Rezaei, S.G. Shabestari, S.H. Razavi, Effect of ECAP consolidation temperature on the microstructure and mechanical properties of Al-Cu-Ti metallic glass reinforced aluminum matrix composite. J. Mater. Sci. Technol. 33(9), 1031–1038 (2017). https://doi.org/10.1016/j.jmst.2016.10.013

R.G. Ding et al., Effect of ECAP on microstructure and mechanical properties of ZE41 magnesium alloy. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 527(16–17), 3777–3784 (2010). https://doi.org/10.1016/j.msea.2010.02.030

K.R. Cardoso et al., Effect of equal channel angular pressing (ECAP) on microstructure and properties of Al-FeAlCr intermetallic phase composites. Mater. Res. Ibero Am. J. Mater. 17(3), 775–780 (2014). https://doi.org/10.1590/S1516-14392014005000029

M.H. Shaeri et al., Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater. Des. 57, 250–257 (2014). https://doi.org/10.1016/j.matdes.2014.01.008

G. Gonzalez et al., Microstructure and texture of Al-2Si-xSn (x = 0, 4, 8 mass%) alloys processed by equal channel angular pressing. Mater. Trans. 53(7), 1234–1239 (2012). https://doi.org/10.2320/matertrans.M2012011

I. Khoubrou, B. Nami, S.M. Miresmaeili, Investigation on the creep behavior of AZ91 magnesium alloy processed by severe plastic deformation. Met. Mater. Int. 26(2), 196–204 (2020). https://doi.org/10.1007/s12540-019-00318-y

W. Abdel-Aziem et al., Microstructure evolution of AA1070 aluminum alloy processed by micro/meso-scale equal channel angular pressing. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00544-4

T. Khelfa et al., Microstructure and mechanical properties of AA6082-T6 by ECAP under warm processing. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00388-y

R. Meshkabadi et al., Combined effects of ECAP and subsequent heating parameters on semi-solid microstructure of 7075 aluminum alloy. Trans. Nonferrous Metals Soci. China 26(12), 3091–3101 (2016). https://doi.org/10.1016/S1003-6326(16)64441-2

R. Meshkabadi et al., Microstructure and homogeneity of semi-solid 7075 aluminum tubes processed by parallel tubular channel angular pressing. Met. Mater. Int. 23(5), 1019–1028 (2017). https://doi.org/10.1007/s12540-017-6760-3

R. Meshkabadi et al., An enhanced steady-state constitutive model for semi-solid forming of Al7075 based on cross model. Metall. Mater. Trans. A 48(9), 4275–4285 (2017). https://doi.org/10.1007/s11661-017-4192-9

R. Howard, N. Bogh, D.S. McKenzie, Heat treating processes and equipment. Handb. Alumin. Metall. Processes 1, 911–920 (2003)

G.Z. Quan et al., A characterization for the dynamic recrystallization kinetics of as-extruded 7075 aluminum alloy based on true stress–strain curves. Comput. Mater. Sci. 55, 65–72 (2012). https://doi.org/10.1016/j.commatsci.2011.11.031

S.R. Kumar et al., Microstructural and mechanical properties of Al 7075 alloy processed by equal channel angular pressing. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 533, 50–54 (2012). https://doi.org/10.1016/j.msea.2011.11.031

C. Xu, T.G. Langdon, The development of hardness homogeneity in aluminum and and aluminum alloy processed by ECAP. J. Materi. Sci. 42, 1542–1550 (2007). https://doi.org/10.1007/s10853-006-0899-5

P.B. Berbon et al., Influence of pressing speed on microstructural development in equal channel angular pressing. Metall. Mater. Trans. A 30(8), 1989–1997 (1999). https://doi.org/10.1007/s11661-999-0009-9

I. Balasundar, M.S. Rao, T. Raghu, Equal channel angular pressing die to extrude a variety of materials. Mater. Des. 30(4), 1050–1059 (2009). https://doi.org/10.1016/j.matdes.2008.06.057

P. Malek, M. Cieslar, R.K. Islamgaliev, The influence of ECAP temperature on the stability of Al–Zn–Mg-Cu alloy. J. Alloy. Compd. 378(1–2), 237–241 (2004). https://doi.org/10.1016/j.jallcom.2003.11.161

P.W.J. Mckenzie, R. Lapovok, Y. Estrin, The influence of back pressure on ECAP processed AA 6016: modeling and experiment. Acta Mater. 55(9), 2985–2993 (2007). https://doi.org/10.1016/j.actamat.2006.12.038

K.S. Ghosh, N. Gao, M.J. Starink, Characterization of high pressure torsion processed 7150 Al–Zn–Mg-Cu alloy. Mater. Sci. Eng. A 552, 164–171 (2012). https://doi.org/10.1016/j.msea.2012.05.026

K. Matsuki et al., Microstructural characteristics and superplastic-like behavior in aluminum powder alloy consolidated by equal-channel angular pressing. Acta Mater. 48(10), 2625–2632 (2000). https://doi.org/10.1016/S1359-6454(00)00061-6

L. Qin et al., In-situ observation of crack initiation and propagation in Ti/Al composite laminates during tensile test. J. Alloy. Compd. 712, 69–75 (2017). https://doi.org/10.1016/j.jallcom.2017.04.063

A. Gandhi, Problem solving using Taguchi DOE techniques. J. Ind. Eng. 32(4), 32–45 (2003)

C.C. Tsao, H. Hocheng, Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int. J. Mach. Tools Manuf 44, 1085–1090 (2004). https://doi.org/10.1016/j.ijmachtools.2004.02.019

T. Sakai et al., Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater Sci. 60, 130–207 (2014). https://doi.org/10.1016/j.pmatsci.2013.09.002

Y.H. Zhao et al., Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 52(15), 4589–4599 (2004). https://doi.org/10.1016/j.actamat.2004.06.017

K.R. Cardoso et al., High Strength AA7050 Al alloy processed by ECAP: Microstructure and mechanical properties. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 528(18), 5804–5811 (2011). https://doi.org/10.1016/j.msea.2011.04.007

Van Horn, K.R., Aluminum, American Society for Metals, 2 (1968)

H. Baker, Handbook-alloy phase diagrams. ASM Int. 3, 279–337 (1990)

J.C. Williams, E.A. Starke, Progress in structural materials for aerospace systems. Acta Mater. 51, 5775–5799 (2003). https://doi.org/10.1016/j.actamat.2003.08.023

M. Chegini, M.H. Shaeri, Effect of equal channel angular pressing on the mechanical and tribological behavior of Al–Zn–Mg–Cu alloy. Mater. Charact. 140, 147–161 (2018). https://doi.org/10.1016/j.matchar.2018.03.045

Z. Zhang et al., Research on grain refinement mechanism of 6061 Aluminum alloy processed by combined SPD methods of ECAP and MAC. Materials 11, 1246 (2018). https://doi.org/10.3390/ma11071246

Y.Y. Wang et al., Effect of deformation temperature on the microstructure developed in commercial purity aluminum processed by equal channel angular extrusion. Scr. Mater. 50(5), 613–617 (2004). https://doi.org/10.1016/j.scriptamat.2003.11.027

I. Mazurina et al., Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. Struct. Mate. Prop. Microstruct. Process. 486(1–2), 662–671 (2008). https://doi.org/10.4028/www.scientific.net/MSF.558-559.545

I. Mazurina et al., Grain refinement in aluminum alloy 2219 during ECAP at 250 degrees C. Mater. Sci. Eng. Struct. Mate. Prop. Microstruct. Process. 473(1–2), 297–305 (2008). https://doi.org/10.1016/j.msea.2007.04.112

Acknowledgements

This work was supported by the Atatürk University Scientific Research Projects Coordination Unit. Project Number: FBA-2017-6001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lule Senoz, G.M., Yilmaz, T.A. Optimization of Equal Channel Angular Pressing Parameters for Improving the Hardness and Microstructure Properties of Al–Zn–Mg Alloy by Using Taguchi Method. Met. Mater. Int. 27, 436–448 (2021). https://doi.org/10.1007/s12540-020-00730-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00730-9