Abstract

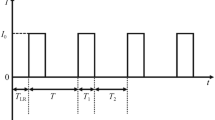

Co–Cr–Fe–Mn–Ni high-entropy alloy thin films were synthesized by pulse electrochemical deposition method. The films were co-deposited in an electrolyte based on a DMF-CH3CN organic system consisting of Co, Cr, Fe, Mn, and Ni cations via the pulse electrodeposition method at 2500 and 5000 Hz frequencies, as well as 50% and 60% duty cycles. The GXRD patterns indicated that films consisted of a single face-centered-cubic structure. The effect of pulsed electrodeposition parameters on wettability and corrosion resistance of coatings was investigated as well. The results of the hydrophobic/hydrophilic test showed that all coatings were completely hydrophilic; the largest wettability angle is for the prepared film at a duty cycle of 50% in frequency of 5000 Hz (56°). The potentiodynamic polarization test results showed that same sample with a corrosion density of 0.067 μA/cm2, improved the corrosion resistance of the substrate due to the superhydrophilic properties of those by about 34 times, and therefore, was chosen as optimal conditions. Also, it was shown that none of the samples were sensitive to pitting corrosion. The results of the EIS test showed an outstanding performance of coatings in improving corrosion resistance compared to similar alloy samples, with a conservation efficiency of about 95%. In addition, it enables the evaluation of continuous changes in the metal-coating system. In such conditions, prepared film at 50% duty cycle in frequency of 5000 Hz improved the corrosion resistance of the substrate by about 40 times.

Graphic Abstract

Similar content being viewed by others

References

J. Yeh et al., Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004)

M.-H. Tsai, J.-W. Yeh, High-entropy alloys: a critical review. Mater. Res. Lett. 2(3), 107–123 (2014)

Y. Qiu, M.A. Gibson, H.L. Fraser, N. Birbilis, Corrosion characteristics of high entropy alloys. Mater. Sci. Technol. 31(10), 1235–1243 (2015)

Y. Shi, B. Yang, P.K. Liaw, Corrosion-resistant high-entropy alloys: a review. Metals (Basel) 7(2), 43 (2017)

Y. Zhang et al., Microstructures and properties of high-entropy alloys. Prog. Mater Sci. 61, 1–93 (2014)

F. Yoosefan, A. Ashrafi, I. Constantin, Synthesis of CoCrFeMnNi high entropy alloy thin films by pulse electrodeposition: part 1: effect of pulse electrodeposition parameters. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00404-1

T. Poornima, N. Jagannatha, A.N. Shetty, Studies on corrosion of annealed and aged 18 Ni 250 grade maraging steel in sulphuric acid medium. Port. Electrochim. Acta 28(3), 173–188 (2010)

Q. Ye et al., Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 396, 1420–1426 (2017)

H. Liu, J. Tao, J. Xu, Z. Chen, Q. Gao, Corrosion and tribological behaviors of chromium oxide coatings prepared by the glow-discharge plasma technique. Surf. Coat. Technol. 204(1–2), 28–36 (2009)

S. Zhang, C.L. Wu, C.H. Zhang, M. Guan, J.Z. Tan, Laser surface alloying of FeCoCrAlNi high-entropy alloy on 304 stainless steel to enhance corrosion and cavitation erosion resistance. Opt. Laser Technol. 84, 23–31 (2016)

H. Torbati-Sarraf, M. Shabani, P.D. Jablonski, G.J. Pataky, A. Poursaee, The influence of incorporation of Mn on the pitting corrosion performance of CrFeCoNi high entropy alloy at different temperatures. Mater. Des. 184, 108170 (2019)

S. Zhao et al., Microstructure and chloride corrosion property of nanocrystalline AlTiCrNiTa high entropy alloy coating on X80 pipeline steel. Surf. Coat. Technol. 375, 215–220 (2019)

Y. Cai, Y. Chen, Z. Luo, F. Gao, L. Li, Manufacturing of FeCoCrNiCux medium-entropy alloy coating using laser cladding technology. Mater. Des. 133, 91–108 (2017)

X. Liu, W. Lei, Q. Wang, W. Tong, C. Liu, J. Cui, Laser surface alloying of low carbon steel using high-entropy alloy precursors. J. Iron. Steel Res. Int. 23(11), 1195–1199 (2016)

Z. Cui, Z. Qin, P. Dong, Y. Mi, D. Gong, W. Li, Microstructure and corrosion properties of FeCoNiCrMn high entropy alloy coatings prepared by high speed laser cladding and ultrasonic surface mechanical rolling treatment. Mater. Lett. 259, 126769 (2019)

S.K. Wong, T.T. Shun, C.H. Chang, C.F. Lee, Microstructures and properties of Al0.3CoCrFeNiMnx high-entropy alloys. Mater. Chem. Phys. 210, 146–151 (2018)

Y. Shi, B. Yang, X. Xie, J. Brechtl, K.A. Dahmen, P.K. Liaw, Corrosion of Al xCoCrFeNi high-entropy alloys: Al-content and potential scan-rate dependent pitting behavior. Corros. Sci. 119, 33–45 (2017)

J. Ding et al., High entropy effect on structure and properties of (Fe Co, Ni, Cr)-B amorphous alloys. J. Alloys Compd. 696, 345–352 (2017)

A. Raphel, S. Kumaran, K.V. Kumar, L. Varghese, Oxidation and corrosion resistance of AlCoCrFeTi high entropy alloy. Mater. Today Proc. 4(2), 195–202 (2017)

C. Shang, E. Axinte, W. Ge, Z. Zhang, Y. Wang, High-entropy alloy coatings with excellent mechanical, corrosion resistance and magnetic properties prepared by mechanical alloying and hot pressing sintering. Surf. Interfaces 9, 36–43 (2017)

J.B. Cheng, X.B. Liang, B.S. Xu, Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings. Surf. Coat. Technol. 240, 184–190 (2014)

A. Aliyu, C. Srivastava, Microstructure and corrosion properties of MnCrFeCoNi high entropy alloy-graphene oxide composite coatings. Materialia 5, 100249 (2019)

P. Kamnerdkhag, M.L. Free, A.A. Shah, A. Rodchanarowan, The effects of duty cycles on pulsed current electrodeposition of ZnNiAl2O3 composite on steel substrate: microstructures, hardness and corrosion resistance. Int. J. Hydrog. Energy 42(32), 20783–20790 (2017)

Z. Duan et al., Oxidation and electrochemical behaviors of Al2O3 and ZrO2 coatings on Zircaloy-2 cladding by thermal spraying. Surf. Coat. Technol. 334, 319–327 (2018)

C. Qian, X. Wu, F. Zhang, W. Yu, Electrochemical impedance investigation of Ni-free Co-Cr-Mo and Co-Cr-Mo-Ni dental casting alloy for partial removable dental prosthesis frameworks. J. Prosthet. Dent. 116(1), 112–118 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yoosefan, F., Ashrafi, A. & Monir vaghefi, S.M. Characterization of Co–Cr–Fe–Mn–Ni High-Entropy Alloy Thin Films Synthesized by Pulse Electrodeposition: Part 2: Effect of Pulse Electrodeposition Parameters on the Wettability and Corrosion Resistance. Met. Mater. Int. 27, 106–117 (2021). https://doi.org/10.1007/s12540-019-00584-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00584-w