Abstract

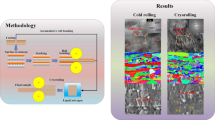

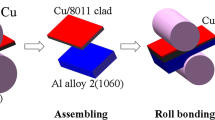

The effect of Ni interlayer on the interface toughening and stability of Cu/Al/Cu clad composite was studied. The peel strength of Cu/Al/Cu composite with Ni interlayer increased with increase of Ni thickness and reached 10.9 N/mm for the composite with 25 μm thick interlayer. The presence of periodic Ni interlayer between Cu and Al hinders the steady crack growth along Cu/Al interface and toughen the interface by inducing the crack deflection away from Cu/Al interface. The peel stress-displacement curves of as-roll-bonded clad exhibited the stress undulation and its amplitude increased with increase of nickel interlayer thickness. The degree of crack deflection was observed to increase with increasing nickel interlayer thickness. The peel strength of Cu/Al/Cu with 25 μm thick Ni interlayer increased up to 14.5 N/mm after annealing at 200 °C, greater than those observed in Cu/Al/Cu with no interlayers. The enhanced Cu/Al bonding and softening of Al matrix by annealing at 200 °C further increased the peel strength because the crack propagated continuously through the ductile Al plate. The formation of pronounced intermetallic compounds at Cu/Al and Ni/Al interfaces after annealing above 400 °C induced the crack growth along the layers of brittle intermetallics and reduced the beneficial effects of Ni interlayer.

Similar content being viewed by others

References

M. Kent, Electr. Veh. Mag. 27, 29 (2016)

K. Oba, Fujikura Tech. Rev. 42, 77 (2013)

A. Uhlemann, A. Herbrandt, PCIM Europe 2012, 680 (2012)

S. Park, S. Nagao, T. Sugahara, K. Suganuma, J. Mater. Sci. 26, 7277 (2015)

I.K. Kim, S.I. Hong, Mater. Des. 47, 590 (2013)

I.K. Kim, S.I. Hong, Mater. Des. 57, 625 (2014)

C.Y. Chen, H.L. Chen, W.S. Hwang, Mater. Trans. 47, 1232 (2006)

M. Abbasi, A.K. Taheri, M.T. Salehi, J. Alloys Compd. 319, 233 (2001)

I.K. Kim, J.S. Ha, S.I. Hong, Korean J. Met. Mater. 50, 939 (2012)

J.-S. Kim, J. Park, K.S. Lee, S. Lee, Y.W. Chang, Met. Mater. Int. 22, 771 (2016)

J.G. Kim, S.M. Baek, W.T. Cho, T.J. Song, K.G. Chin, S.H. Lee, H.S. Kim, Met. Mater. Int. 23, 459 (2017)

Y.B. Zhang, Y. Fu, J.C. Jie, L. Wu, K. S, Q.T. Guo, T.J. Li, T.M. Wang, Met. Mater. Int. 23, 1197 (2017)

M.M. Hoseini-Athar, B. Tolaminejad, Met. Mater. Int. 22, 670 (2016)

D.H. Lee, J.S. Kim, H.J. Song, S.H. Lee, Met. Mater. Int. 23, 805 (2017)

J.H. Cha, S.H. Kim, Y.S. Lee, H.W. Kim, Y.S. Choi, Met. Mater. Int. 22, 880 (2016)

H.L. Yu, C. Lu, A.K. Tieu, H.J. Li, A.R. Godbole, C. Kong, Philos. Mag. 98, 1537 (2018)

H.T. Gao, X.H. Liu, J.L. Qi, Z.R. Ai, L.Z. Liu, J. Mater. Process. Technol. 251, 1 (2018)

B. Guan, B.Y. Chen, Y. Zang, Q. Qin, Strength Mater. 50, 79 (2018)

F. Moisy, A. Gueydan, X. Sauvage, A. Guillet, C. Keller, E. Guilmeau, E. Hug, Mater Des. 155, 366 (2018)

Q. Zhang, S. Li, J. Liu, Y. Wang, B. Zhang, L.Y. Zhang, Metals 8, 329 (2018)

C. Yu, Z.C. Qi, H. Yu, C. Xu, H. Xiao, J. Mater. Eng. Perform. 27, 1664 (2018)

K.S. Lee, S.M. Lee, J.S. Lee, Y.B. Kim, G.A. Lee, S.P. Lee, D.S. Bae, Met. Mater. Int. 22, 880 (2016)

E. Hug, N. Bellido, Mater. Sci. Eng. A 528, 7103 (2011)

I.K. Kim, S.I. Hong, Metall. Mater. Trans. A 44, 3890 (2014)

J.G. Kim, J.H. Ju, D.Y. Kim, S.H. Park, Y.R. Cho, Korean J Met. Mater. 55, 523 (2017)

J.Y. Jin, S.I. Hong, Mater. Sci. Eng. A 596, 1 (2014)

H. Paul, L.L. Dobrzyńska, Metall. Mater. Trans. A 44, 3836 (2013)

A. Shabani, M.R. Toroghinejad, A. Shafyei, Mater. Des. 40, 212 (2012)

J. Zhang, G. Luo, Y. Wang, Q. Shen, L. Zhang, Mater. Lett. 83, 189 (2012)

X.K. Peng, R. Wuhrer, G. Heness, W.Y. Yeung, J. Mater. Sci. 35, 4357 (2000)

J.R. Tuck, A.M. Korsunsky, R.I. Davidson, S.J. Bull, D.M. Elliott, Surf. Coat. Technol. 127, 1 (2000)

C. Barret, T.B. Massalski, Structure of Metals, third ed., revised edn. (Pergamon Press, Oxford, 1980), p. 545

S.I. Hong, M.A. Hill, Acta Mater. 46, 4111 (1998)

S.I. Hong, M.A. Hill, Mater. Sci. Eng. A 281, 189 (2000)

K.H. Lee, S.I. Hong, J. Mater. Res. 18, 2194 (2003)

S.I. Hong, Mater. Sci. Eng. A 711, 492 (2018)

W.N. Kim, S.I. Hong, Mater. Sci. Eng. A 651, 976 (2016)

Acknowledgements

This work was supported by the 3rd phase of the Fundamental R&D Programs for Core Technology of Materials funded by Ministry of Trade, Industry and Energy (Grant No. G011005095104).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, H.J., Hong, S.I. Effect of Ni Interlayer on the Interface Toughening and Thermal Stability of Cu/Al/Cu Clad Composites. Met. Mater. Int. 25, 94–104 (2019). https://doi.org/10.1007/s12540-018-0170-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0170-z