Abstract

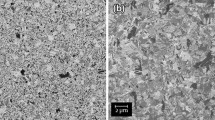

The effect that the deformation state exerts on both the electrical and the mechanical degradation of Cu thin film on a flexible PI substrate was investigated via cyclic sliding test. Two opposite types of deformation (tension and compression) were applied to Cu thin film depending on its outward or inward placement in the cyclic sliding test system. During the cyclic sliding test, the change in electrical resistance of the Cu thin films was monitored using a two-point probe method. Systematic surface observation of deformed Cu thin film under the two opposite types of deformation was performed following specific cycles of sliding motion. Surface observation based on field emission scanning electron microscopy and 3D confocal laser scanning microscopy had been done to quantify the evolution of intrusion extrusions and surface roughness on the deformed Cu thin film. The distribution of microcracks significantly depended on the type of stress/strain applied to the Cu thin film on a flexible PI substrate during the cyclic sliding test. Finite element analysis was performed to explain the deformation behavior of the Cu thin film on a flexible PI substrate during the cyclic sliding test.

Similar content being viewed by others

References

S. Das, R. Gulotty, A.V.V. Sumant, A. Roelofs, Nano Lett. 14, 2861 (2014)

L.-H. Xu, Q.-D. Ou, Y.-Q. Li, Y.-B. Zhang, X.-D. Zhao, H.-Y. Xiang, J.-D. Chen, L. Zhou, S.-T. Lee, J.-X. Tang, ACS Nano 10, 1625 (2016)

S.R. Forrest, Nature 428, 911 (2004)

X. Shen, T. Qian, J. Zhou, N. Xu, T. Yang, C. Yan, A.C.S. Appl, Mater. Interfaces 7, 25298 (2015)

L. Yang, T. Zhang, H. Zhou, S.C. Price, B.J. Wiley, W. You, A.C.S. Appl, Mater. Interfaces 3, 4075 (2011)

T. Someya, T. Sekitani, S. Iba, Y. Kato, H. Kawaguchi, T. Sakurai, Proc. Natl. Acad. Sci. U. S. A. 101, 9966 (2004)

Y. Chen, J. Au, P. Kazlas, A. Ritenour, H. Gates, M. McCreary, Nature 423, 136 (2003)

A. Bag, M.K. Hota, S. Mallik, C.K. Maiti, Semicond. Sci. Technol. 28, 55002 (2013)

A. Bozkurt, A. Lal, Sens. Actuators A Phys. 169, 89 (2011)

J. Gao, P.K. Chow, A.V. Thomas, T.-M. Lu, T. Borca-Tasciuc, N. Koratkar, Appl. Phys. Lett. 105, 123108 (2014)

N. Kränzlin, S. Ellenbroek, D. Durán-Martín, M. Niederberger, Angew. Chem. Int. Ed. 51, 4743 (2012)

M. Hasan, J.F. Rohan, J. Electrochem. Soc. 157, D278 (2010)

Y. Shacham-Diamand, Y. Sverdlov, Microelectron. Eng. 50, 525 (2000)

Y. Shacham-Diamand, V.M. Dubin, Microelectron. Eng. 33, 47 (1997)

Y.-T. Kwon, Y.-I. Lee, S. Kim, K.-J. Lee, Y.-H. Choa, Appl. Surf. Sci. 396, 1239 (2017)

Y. Chang, C. Yang, X.-Y. Zheng, D.-Y. Wang, Z.-G. Yang, A.C.S. Appl, Mater. Interfaces 6, 768 (2014)

I.N. Kholmanov, S.H. Domingues, H. Chou, X. Wang, C. Tan, J.-Y. Kim, H. Li, R. Piner, A.J.G. Zarbin, R.S. Ruoff, ACS Nano 7, 1811 (2013)

N.D. Sankir, R.O. Claus, J. Mater. Process. Technol. 196, 155 (2008)

T. Aizawa, K. Okagawa, M. Kashani, J. Mater. Process. Technol. 213, 1095 (2013)

Y.-T. Kim, J.-H. Kim, D.-K. Kim, Y.-H. Kwon, Int. J. Precis. Eng. Manuf. 16, 981 (2015)

S. Kamiya, H. Furuta, M. Omiya, Surf. Coat. Technol. 202, 1084 (2007)

I.H. Kazi, P.M. Wild, T.N. Moore, M. Sayer, Thin Solid Films 515, 2602 (2006)

B.-I. Noh, J.-W. Yoon, S.-B. Jung, Met. Mater. Int. 16, 779 (2010)

A. Bag, K.-S. Park, S.-H. Choi, Met. Mater. Int. 23, 673 (2017)

S.P. Gorkhali, D.R. Cairns, G.P. Crawford, J. Soc. Inf. Disp. 12, 45 (2004)

M. Amjadi, A. Pichitpajongkit, S. Lee, S. Ryu, I. Park, ACS Nano 8, 5154 (2014)

S. Grego, J. Lewis, E. Vick, D. Temple, J. Soc. Inf. Disp. 13, 575 (2005)

J. Lewis, S. Grego, B. Chalamala, E. Vick, D. Temple, Appl. Phys. Lett. 85, 3450 (2004)

B.-S. Nguyen, J.-F. Lin, D.-C. Perng, A.C.S. Appl, Mater. Interfaces 6, 19566 (2014)

T.C. Li, J.F. Lin, J. Mater. Sci. Mater. Electron. 26, 250 (2014)

C.K. Cho, W.J. Hwang, K. Eun, S.H. Choa, S.I. Na, H.K. Kim, Sol. Energy Mater. Sol. Cells 95, 3269 (2011)

A. Bag, S.-H. Choi, Mater. Charact. 129, 186 (2017)

S.-J. Joo, S.-H. Park, C.-J. Moon, H.-S. Kim, A.C.S. Appl, Mater. Interfaces 7, 5674 (2015)

A. Bag, S.-H. Choi, Mater. Sci. Eng. A 708, 60 (2017)

B.-J. Kim, Y. Cho, M.-S. Jung, H.-A.-S. Shin, M.-W. Moon, H.N. Han, K.T. Nam, Y.-C. Joo, I.-S. Choi, Small 8, 3300 (2012)

B.J. Kim, H.A.S. Shin, J.H. Lee, T.Y. Yan, T. Haas, P. Gruber, I.S. Chou, O. Kraft, Y.C. Joo, J. Mater. Res. 29, 2827 (2014)

B.-J. Kim, T. Haas, A. Friederich, J.-H. Lee, D.-H. Nam, J.R. Binder, W. Bauer, I.-S. Choi, Y.-C. Joo, P.A. Gruber, O. Kraft, Nanotechnology 25, 125706 (2014)

J. Lewis, Mater. Today 9, 38 (2006)

C.-Y. Lim, J.-K. Park, Y. Kim, J.-I. Han, J. Int. Counc. Electr. Eng. 2, 237 (2012)

B. Kim, H. Shin, J. Lee, Y. Joo, Jpn. J. Appl. Phys. 55, 06JF01 (2016)

B. Hwang, H.-A.-S. Shin, T. Kim, Y.-C. Joo, S.M. Han, Small 10, 3397 (2014)

A.B. Kale, A. Bag, J.-H. Hwang, E.G. Castle, M.J. Reece, S.-H. Choi, Mater. Sci. Eng. A 707, 362 (2017)

ARAMIS—3D Motion and Deformation Sensor (2018), https://www.gom.com/metrology-systems/aramis.html. Accessed 8 May 2018

ImageJ—Image Processing and Analysis in Java (2018), https://imagej.nih.gov/ij/. Accessed 8 May 2018

D. Wang, C.A. Volkert, O. Kraft, Mater. Sci. Eng. A 493, 267 (2008)

C.H. Li, P.K.S. Tam, Pattern Recognit. Lett. 19, 771 (1998)

DuPont™ Kapton® Summary of Properties (Du Pont Co., 2017), http://www.dupont.com/content/dam/dupont/products-and-services/membranes-and-films/polyimde-films/documents/DEC-Kapton-summary-of-properties.pdf. Accessed 8 May 2018

C.Y. Kim, J.H. Song, K.J. Park, Trans. Korean Soc. Mech. Eng. A 36, 1529 (2012)

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2015R1D1A1A01057208) and Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2014R1A6A1030419).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bag, A., Park, KS. & Choi, SH. Effect of the Deformation State on the Mechanical Degradation of Cu Metal Films on Flexible PI Substrates During Cyclic Sliding Testing. Met. Mater. Int. 25, 45–63 (2019). https://doi.org/10.1007/s12540-018-0155-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0155-y