Abstract

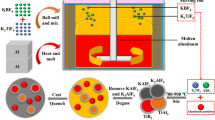

A novel grain refiner consisting of TiC nanoparticles (NPs) supported by Ti powders (abbr. TiC/Ti refiner) was prepared by high-energy milling. The addition of 0.5 wt% TiC/Ti refiner converted the structure of pure Al from coarse dendrites to fine equiaxed grains with the average grain size of 114.7 μm, and it also increased the nucleation temperature of α(Al) from 656.7 to 664.4 °C. When TiC/Ti refiner was introduced into Al melt, the heat released from the Al–Ti reaction promoted the uniform dispersion of TiC NPs. The dissolution of the reaction product TiAl3 released Ti atoms into the melt and thus formed a “Ti-rich transition region” around TiC NPs. The dispersive TiC NPs could act as the heterogeneous nuclei for α(Al) and the “Ti-rich transition region” further improved the lattice orientation relationship between Al (\(\bar{1}1\bar{1}\)) and TiC (\(11\bar{1}\)) planes, which eventually resulted in the refining of α(Al).

Similar content being viewed by others

References

X. Cui, Y. Wu, X. Liu, Q. Zhao, G. Zhang, Mater. Des. 86, 397 (2015)

M. Easton, D. Stjohn, Metall. Mater. Trans. A 30, 1613 (1999)

P. Li, S. Liu, L. Zhang, X. Liu, Mater. Des. 47, 522 (2013)

M.A. Easton, D.H. St. John, Acta Mater. 49, 1867 (2001)

Y. Han, K. Li, J. Wang, D. Shu, B. Sun, Mater. Sci. Eng. A 405, 306 (2005)

Z. Fang, Y. Yang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook, T. Hashimoto, Acta Mater. 84, 292 (2015)

S.M. Jigajinni, K. Venkateswrlu, S.A. Kori, Met. Mater. Int. 19, 171 (2013)

S.A. Kori, B.S. Murty, M. Chakraborty, Mater. Sci. Eng. A 280, 58 (2000)

X.F. Liu, Z.Q. Wang, Z.G. Zhang, X.F. Bian, Mater. Sci. Eng. A 332, 70 (2002)

K. Svynarenko, Y.B. Zhang, J.C. Jie, V. Kutsova, T.J. Li, Met. Mater. Int. 23, 788 (2017)

K. Svynarenko, Y.B. Zhang, J.C. Jie, V. Kutsova, T.J. Li, Met. Mater. Int. 23, 994 (2017)

A. Banerji, W. Reif, Mat. Trans. A 17, 2127 (1986)

H.S. Choi, X.C. Li, J. Mater. Sci. 47, 3096 (2012)

A. Mazahery, H. Abdizadeh, H.R. Baharvandi, Mater. Sci. Eng. A 518, 61 (2009)

S. Fale, A. Likhite, J. Bhatt, Trans. Indian Inst. Met. 68, 291 (2015)

M. Esturga, L.Y. Chen, H.S. Choi, X.C. Li, S. Jin, Appl. Mater. Interfaces 5, 8813 (2013)

K. Wang, H.Y. Jiang, Q.D. Wang, B. Ye, W.J. Ding, J. Mater. Charact. 117, 41 (2016)

G. Levi, W.D. Kaplan, M. Bamberger, Mater. Sci. Eng. A 326, 288 (2002)

M.P.D. Cicco, L.S. Turng, X.C. Li, J.H. Perepezko, Mat. Trans. A 42, 2323 (2011)

H. Su, W.L. Gao, Z.H. Feng, Z. Lu, Mater. Des. 36, 590 (2012)

X. Li, Y. Yang, X. Cheng, J. Mater. Sci. 39, 3211 (2004)

C.A. León, R.A.L. Drew, Compos. Part A Appl. S 33, 1429 (2002)

J.P. Rocher, J.M. Quenisset, R. Naslain, J. Mater. Sci. 24, 2697 (1989)

S. Cai, Y. Li, Y. Chen, X. Li, L. Xue, T. Nonferr, Metal. Soc. 23, 1890 (2013)

X. Li, Q. Cai, B. Zhao, Y. Xiao, B. Li, J. Alloys Compd. 675, 201 (2016)

M. Easton, D. Stjohn, Metall. Mater. Trans. A 30, 1625 (1999)

D. Zhang, D. Ying, Mater. Sci. Eng. A 301, 90 (2011)

V.I. Nikitin, J.I.E. Wanqi, E.G. Kandalova, A.G. Makarenko, L. Yong, Scr. Mater. 42, 561 (2000)

B.L. Smith, P.R. Gardner, E.H.C. Parker, J. Chem. Phys. 47, 1148 (1967)

W.A. Zisma, Adv. Chem. 43, 1 (1964)

M. Jamshidi, F.A. Taromi, J. Adhes. Sci. Technol. 21, 169 (2007)

H. Kamusewitz, W. Possart, Appl. Phys. A Mater. 76, 899 (2003)

S.K. Rhee, J. Am. Ceram. Soc. 53, 386 (1970)

D. Batalu, G. Cosmeleata, A. Aloman, UPB Sci. Bull. 68, 77 (2006)

M.M. Guzowski, G.K. Sigworth, D.A. Sentner, Metall. Mater. Trans. A 18, 603 (1987)

Z. Luo, Y. Song, S. Zhang, D.J. Miller, Metall. Mater. Trans. A 43, 281 (2012)

T. Yano, H. Suematsu, T. Iseki, J. Mater. Sci. 23, 3362 (1988)

B.L. Bramfitt, Metall. Trans. 1, 1987 (1970)

M. Li, H. Zhai, Z. Huang, X. Liu, Y. Zhou, S. Li, C. Li, Mater. Sci. Eng. A 588, 335 (2013)

B. Prabhu, C. Suryanarayana, L. An, R. Vaidyanathan, Mater. Sci. Eng. A 425, 192 (2006)

R. Mitra, W.A. Chiou, M.E. Fine, J.R. Weertman, J. Mater. Res. 8, 2380 (1993)

L. Yu, X. Liu, J. Mater. Process Tech. 182, 519 (2007)

P.S. Mohanty, J.E. Gruzleski, Acta Mater. 43, 2001 (1995)

T.E. Quested, J. Mater. Sci. Technol. 20, 1357 (2004)

J. Qin, G. Chen, B. Wang, N. Hu, F. Han, Z. Du, J. Alloys Compd. 653, 32 (2015)

N.L. Yue, L. Lu, M.O. Lai, Compos. Struct. 47, 691 (1999)

T. Chen, R. Wang, Y. Ma, Y. Hao, Mater. Des. 34, 637 (2012)

V.H. López, A. Scoles, A.R. Kennedy, Mater. Sci. Eng. A 356, 316 (2003)

Acknowledgments

This work was financially supported by the Important National Science and Technology Specific Project of China (No. 2012ZX04010-081). The authors would also thank the support from State Key Laboratory of Material Processing and Die & Mould Technology and Analytical and Testing Center of Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, B., Cai, Q., Li, X. et al. Effect of TiC Nanoparticles Supported by Ti Powders on the Solidification Behavior and Microstructure of Pure Aluminum. Met. Mater. Int. 24, 945–954 (2018). https://doi.org/10.1007/s12540-018-0122-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0122-7