Abstract

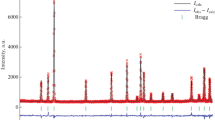

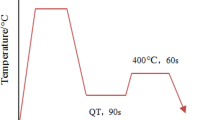

An addition of boron largely increases the ductility in polycrystalline high-temperature Co–Re alloys. Therefore, the effect of boron on the alloy structural characteristics is of high importance for the stability of the matrix at operational temperatures. Volume fractions of ε (hexagonal close-packed—hcp), γ (face-centered cubic—fcc) and σ (Cr2Re3 type) phases were measured at ambient and high temperatures (up to 1500 °C) for a boron-containing Co–17Re–23Cr alloy using neutron diffraction. The matrix phase undergoes an allotropic transformation from ε to γ structure at high temperatures, similar to pure cobalt and to the previously investigated, more complex Co–17Re–23Cr–1.2Ta–2.6C alloy. It was determined in this study that the transformation temperature depends on the boron content (0–1000 wt. ppm). Nevertheless, the transformation temperature did not change monotonically with the increase in the boron content but reached a minimum at approximately 200 ppm of boron. A probable reason is the interplay between the amount of boron in the matrix and the amount of σ phase, which binds hcp-stabilizing elements (Cr and Re). Moreover, borides were identified in alloys with high boron content.

Similar content being viewed by others

References

J. Rösler, D. Mukherji, T. Baranski, Adv. Eng. Mater. 9, 876 (2007)

D. Mukherji, P. Strunz, R. Gilles, M. Hofmann, F. Schmitz, J. Rösler, J. Mater. Lett. 64, 2608–2611 (2010)

D. Mukherji, P. Strunz, S. Piegert, R. Gilles, M. Hofmann, M. Hoelzel, J. Rösler, Metall. Mater. Trans. 43A, 1834–1844 (2012)

D. Mukherji, J. Rösler, J. Wehrs, P. Strunz, P. Beran, R. Gilles, M. Hofmann, M. Hoelzel, H. Eckerlebe, L. Szentmiklósi, Z. Mácsik, Metall. Mater. Trans. 44A, 22–30 (2013). https://doi.org/10.1007/s11661-012-1363-6

R. Gilles, D. Mukherji, L. Karge, P. Strunz, P. Beran, B. Barbier, A. Kriele, M. Hofmann, H. Eckerlebe, J. Roesler, J. Appl. Cryst. 49, 1253–1265 (2016). https://doi.org/10.1107/S1600576716009006

R. Gilles, P. Strunz, D. Mukherji, M. Hofmann, M. Hoelzel, J. Roesler, J. Phys. Conf. Ser. 340, 012052 (2012). https://doi.org/10.1088/1742-6596/340/1/012052

D. Mukherji, J. Roesler, M. Kruger, M. Heilmaier, M.-C. Bolitz, R. Volkl, U. Glatzel, L. Szentmiklosi, Scr. Mater. 66, 60–63 (2012)

M.C. Boelitz, M. Brunner, R. Voelkl, D. Mukherji, J. Roesler, U. Glatzel, Int. J. Mat. Res. 103, 554–558 (2012)

D. Mukherji, R. Gilles, L. Karge, P. Strunz, P. Beran, H. Eckerlebe, A. Stark, L. Szentmiklosi, Z. Macsik, G. Schumacher, I. Zizak, M. Hofmann, M. Hoelzel, J. Roesler, J. Appl. Cryst. 47, 1417–1430 (2014)

D. Mukherji, P. Strunz, R. Gilles, L. Karge, J. Rosler, Kovove Mater. 53, 287–294 (2015). https://doi.org/10.4149/km20154287

M. Hofmann, R. Schneider, G.A. Seidl, J. Kornmeier, R. Wimpory, U. Garbe, H.G. Brokmeier, Phys. B 385–368, 1035 (2006)

R. Gilles, M. Hoelzel, M. Schlapp, F. Elf, B. Krimmer, H. Boysen, H. Fuess, Z. Kristallogr. Suppl. 23, 183 (2006)

M. Hoelzel, A. Senyshyn, N. Juenke, H. Boysen, W. Schmahl, H. Fuess, Nucl. Instrum. Methods Phys. Res. A 667, 32–37 (2012). https://doi.org/10.1016/j.nima.2011.11.070

M.C. Paulisch, N. Wanderka, G. Miehe, D. Mukherji, J. Rösler, J. Banhart, Characterization of borides in Co–Re–Cr-based high-temperature alloys. J. Alloy. Compd. 569, 82–87 (2013)

J. Rodríguez-Carvajal, Phys. B Condens. Matter. 192, 55 (1993)

P. Beran, D. Mukherji, P. Strunz, R. Gilles, M. Hofmann, L. Karge, O. Dolotko, J. Rösler, Met. Mater. Int. 22, 562–571 (2016). https://doi.org/10.1007/s12540-016-5697-2

A.M. Beltran, Cobalt-Base Alloys, in Superalloys II, ed. by C.T. Sims, N.S. Stoloff, W.C. Hagel (Wiley, New York, 1987), p. 141

Acknowledgements

The authors thank MLZ Garching, Germany, and CANAM (NPI Řež, CZ MSMT infrastructural project No. LM2015056), Czech Republic, for providing the beamtime for neutron scattering measurements and tests. P. Strunz, P. Beran and G. Farkas acknowledge support by the GACR project no. 14-36566G. The authors would like to thank the German Research Foundation (DFG) for providing the financial support for the joint Co–Re alloy development project at TU Braunschweig and TU München (RO 2045/31-1 and GI 242/4-1, respectively).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Strunz, P., Mukherji, D., Beran, P. et al. Matrix Transformation in Boron Containing High-Temperature Co–Re–Cr Alloys. Met. Mater. Int. 24, 934–944 (2018). https://doi.org/10.1007/s12540-018-0121-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0121-8