Abstract

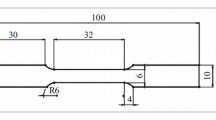

This paper proposes a statistical approach to analyze the mechanical properties of a standard test specimen, of cylindrical geometry and in steel 4340, with a diameter of 6 mm, heat-treated and quenched in three different fluids. Samples were evaluated in standard tensile test to access their characteristic quantities: hardness, modulus of elasticity, yield strength, tensile strength and ultimate deformation. The proposed approach is gradually being built (a) by a presentation of the experimental device, (b) a presentation of the experimental plan and the results of the mechanical tests, (c) anova analysis of variance and a representation of the output responses using the RSM response surface method, and (d) an analysis of the results and discussion. The feasibility and effectiveness of the proposed approach leads to a precise and reliable model capable of predicting the variation of mechanical properties, depending on the tempering temperature, the tempering time and the cooling capacity of the quenching medium.

Similar content being viewed by others

Abbreviations

- Ac3 :

-

Heating temperature at point A3 (°C)

- T :

-

Oven temperature (°C)

- ORT:

-

Oven residence time (min)

- HTC:

-

Heat transfer coefficient (W m−2 K−1)

- RaD :

-

Rayleigh number

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- k :

-

Thermal conductivity of the material (W m−1 K−1)

- T s :

-

Surface temperature of the material (°C)

- T ∞ :

-

Ambient air temperature (°C)

- D :

-

Diameter of the specimen (mm)

- ϑ :

-

Kinematic viscosity (m2 s−1)

- α :

-

Thermal diffusivity (m2 s−1)

- g :

-

Gravitational acceleration (m s−2)

- T f :

-

Average temperature between Ts and T∞ (°C)

- Bi:

-

Biot number

- h :

-

Thermal transfer coefficient (W m−2 K−1)

- C p :

-

Specific heat (J kg−1 K−1)

- ρ :

-

Density (kg m−3)

- S :

-

Surface of the sample (m2)

- V :

-

Volume of the sample (m3)

- S y :

-

Offset yield strength (MPa)

- S u :

-

Ultimate tensile strength (MPa)

- E r :

-

Elongation at break (mm mm−1)

- \({\mathcal{H}}\) :

-

Hardness, HRC (Rockwell C)

- P :

-

Prediction polynomial

References

W.-S. Lee, S. Tzay-Tian, Mechanical properties and microstructural features of AISI 4340 high-strength alloy steel under quenched and tempered conditions. J. Mater. Process. Technol. 87(1), 198–206 (1999)

T.V. Philip, T.J. McCaffrey, Properties and Selection: Irons, Steels, and High-Performance Alloys, ASM Handbook, vol. 1 (ASM International, Materials Park, OH, 1990), pp. 430–448

R.K. Shiue, C. Chen, Laser transformation hardening of tempered 4340 steel. Metall. Mater. Trans. A 23(1), 163–170 (1992)

M. Jahazi, B. Egbali, The influence of hot rolling parameters on the microstructure and mechanical properties of an ultra-high strength steel. J. Mater. Process. Technol. 103, 276–279 (2000)

J.J. Kai et al., The effects of heat treatment on the chromium depletion, precipitate evolution, and corrosion resistance of INCONEL alloy 690. Metall. Mater. Trans. A 20(10), 2057–2067 (1989)

H. Cheng, H. Wang, X. Huang, Calculation of thermal stress field with non-linear surface heat-transfer coefficient during quenching. Met. Mater. 4(4), 601–604 (1998)

Y.V. Murty, T.Z. Kattamis, R. Mehrabian, M.C. Flemings, Behavior of sulfide inclusions during thermomechanical processing of AISI 4340 steel. Metall. Mater. Trans. A 8, 1275–1282 (1977)

ASTM E8/E8M. Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken (2009)

K. Liu, X. Cao, X.-G. Chen, Tensile properties of Al–Cu 206 cast alloys with various iron contents. Metall. Mater. Trans. A 45(5), 2498–2507 (2014)

D. Shahriari, M.H. Sadeghi, A. Akbarzadeh, M. Cheraghzadeh, The influence of heat treatment and hot deformation conditions on g′ precipitate dissolution of Nimonic 115 superalloy. Int. J. Adv. Manuf. Technol. 45, 841–850 (2009)

J. Datsko, L. Hartwig, B. McClorv, On the tensile strength and hardness relation for metals. J. Mater. Eng. Perform. 10, 718–722 (2001)

Phillip J. Ross, Taguchi Techniques for Quality Engineering (McGraw-Hill, London, 1988), p. 66

D.H. Kim, D.J. Kim, D.C. Ko, B.M. Kim, J.C. Choi, The application of the artificial neural network and taguchi method to process sequence design in metal forming processes. Met. Mater. 4(3), 548–553 (1998)

Stuart W. Churchill, Humbert H.S. Chu, Correlating equations for laminar and turbulent free convection from a vertical plate. Int. J. Heat Mass Transf. 18, 1323–1329 (1975)

K. Dehnad, Quality Control, Robust Design, and the Taguchi Method (Springer, New York, 1989)

K. Palanikumar, L. Karunamoorthy, R. Karthikeyan, B. Latha, Optimization of machining parameters in turning GFRP composites using a carbide (K10) tool based on the Taguchi method with fuzzy logics. Met. Mater. Int. 12(6), 483–491 (2006)

R.H. Myers, Response Surface Methodology (Allyn and Bacon, Boston, MA, 1971)

K. Dehghani, A. Nekahi, Interactive effects of aging parameters of AA6056. Met. Mater. Int. 18(5), 757–767 (2012)

G.Y. Lai et al., The effect of austenitizing temperature on the microstructure and mechanical properties of as-quenched 4340 steel. Metall. Trans. 5(7), 1663–1670 (1974)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fakir, R., Barka, N. & Brousseau, J. Mechanical Properties Analysis of 4340 Steel Specimen Heat Treated in Oven and Quenching in Three Different Fluids. Met. Mater. Int. 24, 981–991 (2018). https://doi.org/10.1007/s12540-018-0120-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0120-9