Abstract

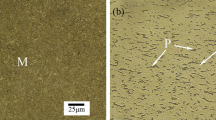

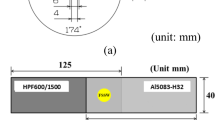

Resistance nut projection weldability of Al–Si coated hot stamped steel (HSS) was investigated under the viewpoint of weldable current range and joint strength (pull-out load). The microstructural inhomogeneities in the welds were also studied in order to elucidate the factors affecting the joint strength of the welds. The weldability of the given Al–Si coated HSS was compared with the weldability of an identical HSS without the Al–Si coating (Al–Si coating was polished out) and Zn coated dual phase steel. The weldable current range of Al–Si coated HSS was found to be narrower than that of the other materials. Furthermore, the average pull-out load within the weldable current range of the Al–Si coated HSS was the lowest among the three materials. The reason for poor weld mechanical property of the Al–Si coated hot-stamped steel was attributed to the microstructural inhomogeneities such as unmixed Al–Si coating layer at the edge of the nugget and the second phase Fe3(Al, Si) intermetallic compound. The formation of Fe3(Al, Si) phase was attributed to the solidification segregation of Al and Si during the weld solidification and was confirmed with the numerical analysis of solidification segregation.

Similar content being viewed by others

References

H. Karbasian, A.E. Tekkaya, A review on hot stamping. J. Mater. Process. Technol. 210, 2103–2118 (2010)

M. Merklein, M. Wieland, M. Lechner, S. Bruschi, A. Ghiotti, Hot stamping of boron steel sheets with tailored properties: a review. J. Mater. Process. Technol. 228, 11–24 (2016)

W. Windmann, A. Rottger, W. Theisen, Formation of intermetallic phases in Al-coated hot-stamped 22MnB5 sheets in terms of coating thickness and Si content. Surf. Coat. Technol. 246, 17–25 (2014)

S.S. Lim, Y.T. Kim, E.J. Chun, K.S. Nam, Y.W. Park, J.W. Kim, S.Y. Lee, I.D. Choi, Y.D. Park, Effect of chemical composition of nut material on the fracture behaviour in nut projection welding of hot-stamped steel sheet. J. Weld. Join. 34, 1–10 (2016)

E. Tolf, J. Hedegard, Resistance nut welding: improving the weldability and joint properties of ultra high strength steels. Weld. World 51, 28–36 (2007)

C.V. Nielsen, W. Zhang, P.A.F. Martins, N. Bay, 3D numerical simulation of projection welding of square nuts to sheets. J. Mater. Process. Technol. 215, 171–180 (2015)

C.W. Ji, I.D. Choi, Y.D. Kim, Y.D. Park, Study on coating melting behaviour on weld growth mechanism for Al–Si coated hot-stamped boron steels in resistance spot welding. Korean J. Met. Mater. 52, 931–941 (2014)

C.W. Ji, I. Jo, H. Lee, I.D. Choi, Y.D. Kim, Y.D. Park, Effects of surface coating on weld growth of resistance spot-welded hot-stamped boron steels. J. Mech. Sci. Technol. 28, 4761–4769 (2014)

D.C. Saha, C.W. Ji, Y.D. Park, Coating behaviour and nugget formation during resistance welding of hot forming steels. Sci. Technol. Weld. Join. 20, 708–720 (2015)

H.S. Choi, G.H. Park, W.S. Lim, B.M. Kim, Evaluation of weldability for resistance spot welded single-lap joint between GA780DP and hot-stamped 22MnB5 steel sheets. J. Mech. Sci. Technol. 25, 1543–1550 (2011)

O.L. Ighodaro, E. Biro, Y.N. Zhou, Comparative effects of Al–Si and galvannealed coatings on the properties of resistance spot welded hot stamping steel joints. J. Mater. Process. Technol. 236, 64–72 (2016)

M. Tumuluru, The effect of coatings on the resistance spot welding behaviour of 780 MPa dual-phase steel. Weld. J. 86, 161s–169s (2007)

M.S. Kwon, C.Y. Kang, Segregation and microstructure in the fusion zones of laser joints of Al–10%Si coated boron steel. Korean J. Met. Mater. 54, 40–48 (2016)

M. Amirthalingam, E.E. van der Aa, C. Kwakernaak, M.J.M. Hermans, I.M. Richardson, Elemental segregation during resistance spot welding of boron containing advanced high strength steels. Weld. World 59, 743–755 (2015)

Y. Zhuo, P. Gorman, W. Tan, K.J. Ely, Weldability of thin sheet metals during small-scale resistance spot welding using an alternating-current power supply. J. Electron. Mater. 29, 1090–1099 (2000)

S.P. Murugan, M. Cheepu, D.G. Nam, Y.D. Park, Weldability and fracture behaviour of low carbon steel/aluminium/stainless steel clad sheet with resistance spot welding. Trans. Ind. Inst. Met. 70(2017), 759–768 (2017)

M. Morishita, H. Ishida, M. Yoshida, Modelling of microsegregation and precipitation of iron metallic compounds in Al–Fe–Si ternary alloy. J. Jpn. Inst. Light Met. 60, 157–163 (2010)

E.J. Chun, K. Nishimoto, K. Saida, Evaluation of solidification cracking susceptibility in laser welds for type 316FR stainless steel. Weld. World 60, 217–231 (2016)

K. Saida, H. Matsushita, K. Nishimoto, K. Kiuch, J. Nakayama, Quantitative influence of minor and impurity elements of solidification cracking susceptibility of extra high purity type 310 stainless steel. Sci. Technol. Weld. Join. 18, 616–623 (2013)

M.J. Aziz, Model for solute redistribution during rapid solidification. J. Appl. Phys. 53, 1158–1168 (1982)

The Japan Institute of Metals and Materials (ed.), Metals Handbook (Maruzen, Tokyo, 2004), pp. 20–25

Y. Ono, Diffusion in liquid iron and its alloys. Tetsu-to-Hagane 63, 1350–1361 (1977)

Z. Morita, T. Tanaka, Thermodynamics on the equilibrium distribution coefficients of solute elements between solid and liquid phases in iron alloys. Tetsu-to-Hagane 74, 543–552 (1988)

V. Raghavan, Al–Fe–Si (Aluminium–Iron–Silicon). J. Phase Equilib. 23, 362–366 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chun, EJ., Lim, SS., Kim, YT. et al. Influence of heat-treated Al–Si coating on the weldability and microstructural inhomogeneity for hot stamped steel resistance nut projection welds. Met. Mater. Int. 25, 179–192 (2019). https://doi.org/10.1007/s12540-018-0108-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0108-5