Abstract

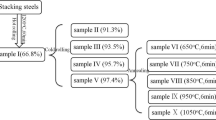

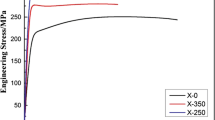

An austenitic Hadfield steel was roll-bonded with a 1.8-GPa-strength-grade martensitic hot-press-forming (HPF) steel to fabricate a multi-layer steel (MLS) sheet. Near the Hadfield/HPF interface, the carburized and decarburized layers were formed by the carbon diffusion from the Hadfield (1.2%C) to HPF (0.35%C) layers, and could be regarded as kinds of very thin multi-layers of 35 μm in thickness. The tensile test and fractographic data indicated that the MLS sheet was fractured abruptly within the elastic range by the intergranular fracture occurred in the carburized layer. This was because C was mainly segregated at prior austenite grain boundaries in the carburized layer, which weakened grain boundaries to induce the intergranular fracture. In order to solve the intergranular facture problem, the MLS sheet was tempered at 200 °C. The stress–strain curve of the tempered MLS sheet lay between those of the HPF and Hadfield sheets, and a rule of mixtures was roughly satisfied. Tensile properties of the MLS sheet were dramatically improved after the tempering, and the intergranular fracture was erased completely. In particular, the yield strength up to 1073 MPa along with the high strain hardening and excellent ductility of 32.4% were outstanding because the yield strength over 1 GPa was hardly achieved in conventional austenitic steels.

Similar content being viewed by others

References

G. Frommeyer, U. Brüx, P. Neumann, ISIJ Int. 43, 438 (2003)

S. Vercammen, B. Blanpain, B.C. De Cooman, P. Wollants, Acta Mater. 52, 2005 (2004)

I. Gutierrez-Urrutia, S. Zaefferer, D. Raabe, Mater. Sci. Eng. A 527, 3552 (2010)

G. Dini, A. Najafizadeh, R. Ueji, S.M. Monir-Vaghefi, Mater. Lett. 64, 15 (2010)

B.H. Park, H.Y. Um, J.G. Kim, H.Y. Jeong, S. Lee, H.S. Kim, Met. Mater. Int. 22, 1003 (2016)

K.K. Ryoo, M.-Y. Ha, K.D. Lee, Korean J. Met. Mater. 54, 711 (2016)

K.H. So, J.S. Kim, Y.S. Chun, K.-T. Park, Y.-K. Lee, C.S. Lee, ISIJ Int. 49, 1952 (2009)

L. Chen, H.-S. Kim, S.-K. Kim, B.C. De Cooman, ISIJ Int. 47, 1804 (2007)

L. Zaho, N.H.V. Dijk, A.J.E. Lefering, J. Sietsma, J. Mater. Sci. 48, 1474 (2013)

G. Jung, I.S. Woo, D.W. Suh, S.-J. Kim, Met. Mater. Int. 22, 187 (2016)

O. Kwon, K.Y. Lee, G.S. Kim, K.G. Chin, Mater. Sci. Forum 638–642, 136 (2010)

R. Ueji, N. Tsuchida, D. Terada, N. Tsuji, Y. Tanaka, A. Takemura, K. Kunishige, Scripta Mater. 59, 963 (2008)

L. Li, S. Liu, B. Ye, S. Hu, Z. Zhou, Met. Mater. Int. 22, 391 (2016)

O. Bouaziz, J.P. Masse, G. Petitgand, M.X. Huang, Adv. Eng. Mater. 18, 56 (2016)

S. Nambu, M. Michiuchi, J. Inoue, T. Koseki, Compos. Sci. Technol. 69, 1936 (2009)

J.-H. Cha, S.-H. Kim, Y.-S. Lee, H.-W. Kim, Y.S. Choi, Met. Mater. Int. 22, 880 (2016)

J. Inoue, S. Nambu, Y. Ishimoto, T. Koseki, Scr. Mater. 59, 1055 (2008)

J.I. Yoon, J.G. Kim, J.M. Jung, D.J. Lee, H.J. Jeong, M. Shahbaz, S. Lee, H.S. Kim, Korean J. Met. Mater. 54, 231 (2016)

S.-J. Lee, Y.-M. Park, Y.-K. Lee, Mater. Sci. Eng. A 515, 32 (2009)

H.J. Sung, N.H. Heo, S.-J. Kim, Met. Mater. Int. 22, 962 (2016)

B.X. Liu, F.X. Yin, X.L. Dai, J.N. He, W. Fang, C.X. Chen, Y.C. Dong, Mater. Sci. Eng. A 679, 172 (2017)

Y.N. Dastur, W.C. Leslie, Metall. Trans. A 12, 749 (1981)

Acknowledgements

This work was supported by POSCO under a Contract No. 2014Y015 and by Brain Korea 21 PLUS Project for Center for Creative Industrial Materials. The authors would like to thank to Dr. Taejin Song of POSCO for the fabrication of the Hadfield-cored MLS sheet.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chin, KG., Kang, CY., Park, J. et al. Fabrication of Hadfield-Cored Multi-layer Steel Sheet by Roll-Bonding with 1.8-GPa-Strength-Grade Hot-Press-Forming Steel. Met. Mater. Int. 24, 489–495 (2018). https://doi.org/10.1007/s12540-018-0081-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0081-z