Abstract

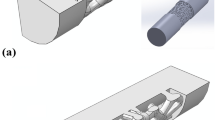

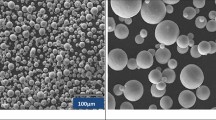

Porous materials were developed as a good alternative to replace different bones in the human body as they improve osseointegration, tissue ingrowth and simulate the mechanical properties of human bones. Such characteristics highly depend on the pore features and volume fraction. Samples with a pore volume fraction between 16 and 60% and a pore size distribution of 100–500 µm were analyzed by computed microtomography. 3D images acquisition was performed at 10 µm pixel resolution, which permitted to observe the complete sample. Features like size, shape, orientation, connectivity and pore coordination were determined from the 3D image analysis. Compression behavior was evaluated by interrupted compression testing and, after that, new 3D images were acquired. In order to evaluate permeability, numerical simulations of flow throughout the 3D images were carried out by using Avizo® software. It was found that shape and pore size distribution was similar in all samples, showing good distribution of the pore formers inside the matrix. Full connectivity of pores was obtained with 32% volume fraction and above, and the coordination number follows the Artz model. The pores showed a radial orientation, which induces anisotropy in the flow properties. The compression showed two different behaviors, pore closing and pore coalescence. Values of permeability match with those reported for bones as well as the anisotropy in the radial and vertical directions. It is concluded that the sample with 60 vol% of pores could be consider to be used for bone implants.

Similar content being viewed by others

References

X. Wang, S. Xu, S. Zhou, W. Xu, M. Leary, P. Choong, M. Qian, M. Brandt, Y.M. Xie, Biomaterials (2016). https://doi.org/10.1016/j.biomaterials.2016.01.012

L.E. Murr, S.M. Gaytan, E. Martinez, F. Medina, R.B. Wicker, Int. J. Biomater. (2012). https://doi.org/10.1155/2012/245727

Q.Z. Chen, I.D. Thompson, A.R. Boccaccini, Biomaterials (2006). https://doi.org/10.1016/j.biomaterials.2005.11.025

B.R. Levine, S. Sporer, R.A. Poggie, C.J. Della Valle, J.J. Jacobs, Biomaterials (2006). https://doi.org/10.1016/j.biomaterials.2006.04.041

F.A. España, V.K. Balla, S. Bose, A. Bandyopadhyay, Mater. Sci. Eng. C (2010). https://doi.org/10.1016/j.msec.2009.08.006

A. Bansiddhi, T.D. Sargeant, S.I. Stupp, D.C. Dunand, Acta Biomater. (2008). https://doi.org/10.1016/j.actbio.2008.02.009

J. Ballarre, I. Manjubala, W.H. Schreiner, J.C. Orellano, P. Fratzl, S. Ceré, Acta Biomater. (2010). https://doi.org/10.1016/j.actbio.2009.10.015

S.F.S. Shirazi, S. Gharehkhani, M. Mehrali, H. Yarmand, H.S.C. Metselaar, N.A. Kadri, N.A.A. Osman, Sci. Technol. Adv. Mater. (2015). https://doi.org/10.1088/1468-6996/16/3/033502

B. Arifvianto, J. Zhou, Materials (2014). https://doi.org/10.3390/ma7053588

L. Reig, V. Amigó, D.J. Busquets, J.A. Calero, J. Mater. Process. Technol. (2012). https://doi.org/10.1016/j.jmatprotec.2011.06.026

Y. Torres, J.A. Rodríguez, S. Arias, M. Echeverry, S. Robledo, V. Amigo, J.J. Pavón, J. Mater. Sci. (2012). https://doi.org/10.1007/s10853-012-6586-9

J.L. Cabezas-Villa, L. Olmos, D. Bouvard, J. Lemus-Ruiz, O. Jiménez, J. Mater. Res. (2018). https://doi.org/10.1557/jmr.2018.35

J. Jakubowicz, G. Adamek, M. Dewidar, J. Porous Mater. (2013). https://doi.org/10.1007/s10934-013-9696-0

H. Matsuno, A. Yokoyama, F. Watari, M. Uo, T. Kawasaki, Biomaterials (2001). https://doi.org/10.1016/S0142-9612(00)00275-1

J.R. Woodard, A.J. Hilldore, S.K. Lan, C.J. Park, A.W. Morgan, J.A.C. Eurell, S.G. Clark, M.B. Wheeler, R.D. Jamison, A.J.W. Johnson, Biomaterials (2007). https://doi.org/10.1016/j.biomaterials.2006.08.021

H. Montazerian, E. Davoodi, M. Asadi-Eydivand, J. Kadkhodapour, M. Solati-Hashjin, Mater. Des. (2017). https://doi.org/10.1016/j.matdes.2017.04.009

V. Karageorgiou, D. Kaplan, Biomaterials (2005). https://doi.org/10.1016/j.biomaterials.2005.02.002

S.M. Kalantari, H. Arabi, S. Mirdamadi, S.A. Mirsalehi, J. Mech. Behav. Biomed. Mater. (2015). https://doi.org/10.1016/j.jmbbm.2015.04.015

Y. Torres, S. Lascano, J. Bris, J. Pavón, J.A. Rodriguez, Mater. Sci. Eng. C. (2014). https://doi.org/10.1016/j.msec.2013.11.036

Z. Zhang, D. Jones, S. Yue, P.D. Lee, J.R. Jones, C.J. Sutcliffe, E. Jones, Mater. Sci. Eng. C (2013). https://doi.org/10.1016/j.msec.2013.05.050

R. Singh, P.D. Lee, T.C. Lindley, R.J. Dashwood, E. Ferrie, T. Imwinkelried, Acta Biomater. (2009). https://doi.org/10.1016/j.actbio.2008.06.014

M.C. Varley, S. Neelakantan, T.W. Clyne, J. Dean, R.A. Brooks, A.E. Markaki, Acta Biomater. (2016). https://doi.org/10.1016/j.actbio.2016.01.041

M.R. Dias, P.R. Fernandes, J.M. Guedes, S.J. Hollister, J. Biomech. (2012). https://doi.org/10.1016/j.jbiomech.2012.01.019

M.D.M. Innocentini, R.K. Faleiros, R. Pisani Jr., I. Thijs, J. Luyten, S. Mullens, J. Porous Mater. (2010). https://doi.org/10.1007/s10934-009-9331-2

E.A. Nauman, K.E. Fong, T.M. Keaveny, Ann. Biomed. Eng. (1999). https://doi.org/10.1114/1.195

L. Olmos, T. Takahashi, D. Bouvard, C.L. Martin, L. Salvo, D. Bellet, M. Di Michiel, Philos. Mag. (2009). https://doi.org/10.1080/14786430903150225

C.L. Lin, J.D. Miller, Powder Technol. (2005). https://doi.org/10.1016/j.powtec.2005.04.031

L. Olmos, C.L. Martin, D. Bouvard, D. Bellet, M. Di Michiel, J. Am. Ceram. Soc. (2009). https://doi.org/10.1111/j.1551-2916.2009.03037.x

L. Olmos, D. Bouvard, L. Salvo, D. Bellet, M. Di Michiel, J. Mater. Sci. (2014). https://doi.org/10.1007/s10853-014-8117-3

S.A. Saltykov, Stereometrische Metallographie Metallurgizdat (VEB, Leipzig, 1974)

A. Marmottant, L. Salvo, C.L. Martin, A. Mortensen, J. Eur. Ceram. Soc. (2008). https://doi.org/10.1016/j.jeurceramsoc.2008.03.041

A. Vagnon, J.P. Rivière, J.M. Missiaen, D. Bellet, M. Di Michiel, C. Josserond, D. Bouvard, Acta Mater. (2008). https://doi.org/10.1016/j.actamat.2007.11.008

X.Y. Cheng, S.J. Li, L.E. Murr, Z.B. Zhang, Y.L. Hao, R. Yang, F. Medina, R.B. Wicker, J. Mech. Behav. Biomed. Mater. (2012). https://doi.org/10.1016/j.jmbbm.2012.10.005

D. Bouvard, F.F. Lange, Acta Metall. Mater. (1991). https://doi.org/10.1016/0956-7151(91)90041-X

J.X. Lu, B. Flautre, K. Anselme, P. Hardouin, A. Gallur, M. Descamps, B. Thierry, J. Mater. Sci. Mater. Med. (1999). https://doi.org/10.1023/A:1008973120918

R.A. Perez, G. Mestres, Mater. Sci. Eng. C (2016). https://doi.org/10.1016/j.msec.2015.12.087

D.J. Griffon, M.R. Sedighi, D.V. Schaeffer, J.A. Eurell, A.L. Johnson, Acta Biomater. (2006). https://doi.org/10.1016/j.actbio.2005.12.007

E. Arzt, Acta Metall. (1982). https://doi.org/10.1016/0001-6160(82)90028-1

L.J. Gibson, M.F. Ashby, Cellular Solids: Structure and Properties, 2nd edn. (Cambridge University Press, Cambridge, 1999), p. 175

R. Singh, P.D. Lee, T.C. Lindley, C. Kohlhauser, C. Hellmich, M. Bram, T. Imwinkelried, R.J. Dashwood, Acta Biomater. (2010). https://doi.org/10.1016/j.actbio.2009.11.032

I. Farias, L. Olmos, O. Jimenez, H.J. Vergara-Hernández, D. Bouvard, P. Gárnica, M. Flores, Mater. Res. Ibero. Am. J. (2017). https://doi.org/10.1590/1980-5373-mr-2017-0510

M.J. Grimm, J.L. Williams, J. Biomech. (1997). https://doi.org/10.1016/S0021-9290(97)00016-X

F.J. O’Brien, B.A. Harley, M.A. Waller, I.V. Yannas, L.J. Gibson, P.J. Prendergast, Technol. Health Care 15(1), 3 (2007)

C.M. Murphy, M.G. Haugh, F.J. O’Brien, Biomaterials (2010). https://doi.org/10.1016/j.biomaterials.2009.09.063

K. Kieswetter, Z. Schwartz, D.D. Dean, B.D. Boyan, Crit. Rev. Oral Biol. Med. (1996). https://doi.org/10.1177/10454411960070040301

Acknowledgements

The authors would like to thank to the CIC of the UMSNH and ECOS M15P01 for the financial support and the facilities provided for the development of this study. We would also like to thank the Laboratory “LUMIR” Geosciences of the UNAM, Juriquilla, for the 3D image acquisition and processing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olmos, L., Bouvard, D., Cabezas-Villa, J.L. et al. Analysis of Compression and Permeability Behavior of Porous Ti6Al4V by Computed Microtomography. Met. Mater. Int. 25, 669–682 (2019). https://doi.org/10.1007/s12540-018-00223-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-00223-w