Abstract

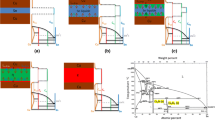

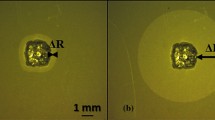

Finite element method is utilized to solve the diffusion equation and model the diffusion driven growth of a pre-existing spherical gas bubble in molten tin at the solder/substrate interface for reflow time of 120 s and temperature of 250 °C. The gibbs free energy change required for determining the equilibrium concentration at liquid solder/gas bubble boundary was calculated using the thermodynamic polynomial coefficients. The rate of change of radius, as function of concentration flux, is calculated using the lagrangian mesh update methodology. With an initial diameter of 20 μm, the bubble growth is calculated as a function of contact angle. When the wetting angle is varied from a value of 30° to 135°, the numerical calculation has yielded the final sizes for the bubble to change from 62.87 μm to 82.8 μm respectively. The effect of wetting transition in the growth of bubble was studied by the in-situ observation of bubble dynamics through synchrotron radiation imaging technique. The scanning electron microscopy images of the morphologies of intermetallic compounds influenced by growing bubble in Sn/Cu solder joint and bubble pictures obtained through synchrotron radiation are utilized to get the experimental size of the bubble. The mean experimental bubble diameter has been obtained as 76.39 μm. The growing bubble inhibits the growth of intermetallic compound at its vicinity and thereby reduces the strength of solder joints.

Similar content being viewed by others

References

T. L Lewis, C. O. Ndiaya, and J. R.Wilcox, IPC APEX EXPO2012 Tech. Conf. Proc., p.747, IPC-Association Connecting Electronic Industries, San Diego, California, USA (2012).

R. F. Aspandiar, J. Surf. Mt. Technol. 19, 28 (2006).

W. B. O’Hara and N.-C, Lee, Solder. Surf. Mt. Technol. 7-3, 44 (1995).

S. Lee, H. M. Zhou, and D. F. Baldwin, Modelling Simul. Mater. Sci. Eng. 18, 065005 (2010).

M. Theriault, J. Uner, and A. Rahn, Handbook of Lead-Free Solder Technology for Microelectronic Assemblies (eds. K. J. Puttlitz and K. A. Stalter), pp.15(1-22), C. R. C. Press (2004).

V. Lyakhovsky, S. Hurwitz, and O. Navon, Bull Volcanol. 58, 19 (1996).

J. Fradera and S. Cuesta-Lopez, Fusion Eng. Des. 88, 3215 (2013).

L. Qu, H. T. Ma, H. J. Zhao, A. Kunwar, and N. Zhao, Appl. Surf. Sci. 305, 133 (2014).

S. Karagadde, S. Sundarraj, and P. Dutta, Scripta Mater. 61, 216 (2009).

Salome Team, Salome: The Open Source Integration Platform for Numerical Simulation, http://www.salome-platform.org (accessed September 23, 2014).

A. Ribes and C. Caremoli, 31st Annual International Computer Software and Applications Conference (COMPSAC 2007), p.553, IEEE Computer Society (2007).

E. M. Sacris and N. A. D. Parlee, Metall. Trans. 1, 3377 (1970).

N. Zhao, X. M. Pan, D. Q. Yu, H. T. Ma, and L. Wang, J. Electron. Mater. 38, 828 (2009).

T. Gancarz, W. Gasior, and H. Henein, Int. J. Thermophys. 34, 250 (2013).

T. Gancarz, Z. Moser, W. Gasior, J. Pstrus, and H. Henein, Int. J. Thermophys. 32, 1210 ( 2011).

X. Hu, Y. Wang, L. Guo, and Z. Cao, Advances in Condensed Matter Physics, 2014, 970891 (2014).

R. Sasikumar, M. J. Walker, S. Savithri, and S. Sundarraj, Modelling Simul. Mater. Sci. Eng. 16, 035009 (2008).

G. R. Jiang, Y. X. Li, and Y. Liu, Trans. Nonferrous Met. Soc. China 21, 1130 (2011).

A. K. Khurana, H. Chen, and C. G. Wall, Chem. Eng. Comm. 165, 199 (1998).

J. O. Suh, K. N. Tu, and N. Tamura, JOM, 63 (2006).

S. Xu, S. Wu, Y. Mao, P. An, and P. Gao, China Foundry 3, 275 (2006).

W. C. Gardiner Jr. (Ed), Combustion Chemistry, pp.455–473, Springer, New York, USA (1984).

A. Burcat, Prof. Burcat’s Thermodynamic Data, http://garfield. chem.elte.hu/Burcat/burcat.html (accessed April 21, 2014).

D. Goodwin, Cantera: Chemical Kinetics Software Package. California Institute for Technology - Caltech, www.cantera.org (accessed August 27, 2013).

Elmer Team at CSC-IT Center for Science Ltd., Elmer, https:// www.csc.fi/web/elmer/elmer (accessed January 5, 014).

E. Jarvinen, P. Raback, M. Lyly, and J.-P. Salenius, Med. Eng. Phys. 30, 917 (2008).

J. Ahrens, B. Geveci, and C. Law, Visualization Handbook (eds. C. D. Hansen and C. R. Johnson), p.717, Elsevier (2005).

U. Ayachit, The ParaView Guide: A Parallel Visualization Application, pp.131–212, Kitware (2015).

M. Ramiasa, J. Ralston, R. Fetzer, and R. Sedev, Advances in Colloid and Interface Science 206, 275 (2014).

D Bonn, J. Eggers, J. Endekeu, J. Meunier, and E. Rolley, Rev. Mod. Phys. 81, 739 (2009).

D. Ertas and M. Kardar, Phys. Rev. E 49, R2532-1(1994).

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s12540-016-0005-8.

Rights and permissions

About this article

Cite this article

Kunwar, A., Ma, H., Sun, J. et al. Modeling the diffusion-driven growth of a pre-existing gas bubble in molten tin. Met. Mater. Int. 21, 962–970 (2015). https://doi.org/10.1007/s12540-015-4528-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4528-1