Abstract

Previous analytical studies show that most of Northern Italian glass has been heavily recycled and that mixing of natron and plant ash glass was occurring (Verità and Toninato 1990; Verità et al. 2002; Uboldi and Verità 2003; Andreescu-Treadgold and Henderson 2006; Silvestri and Marcante 2011). The re-use of “old Roman glass” has been interpreted as stagnation in glass trade from the primary production areas. However, the reintroduction of plant ash glass on sites such as Torcello, Nogara, and in Lombardy at the same time as it was reintroduced in the Levant, strongly indicates long-distance contacts with the Levant at least from the eighth century CE. This paper addresses the key issue of recycling by focusing on the compositional nature of glass traded and reworked in Northern Italy after the seventh century CE set in a broad Mediterranean context by analysing major, minor, and trace elements in eighty-nine glass samples (seventh to the eleventh century AD) from the glass workshop of Piazza XX Settembre, Comacchio. Five major previously proposed compositional groups of glass have been identified from Comacchio (Levantine Apollonia and Jalame types, HIMT, Foy-2, and plant ash glass). The impact of recycling and mixing practices in Comacchio glass is also discussed with the help of known recycling markers and selected ratios (major and trace elements). The mixing between Levantine, HIMT, and plant ash glass is highlighted and end-members of potential natron to natron mixing compositional groups have been identified. The compositional nature of plant ash glass from Northern Italy is discussed in light of their trace element content and production areas.

Similar content being viewed by others

Introduction

From the Roman to the Early Medieval period, large tank furnaces located in Egypt (Nenna 2014) and in the Levant (Gorin-Rosen 2000; Tal et al. 2004) were producing raw glass which was cut into pieces, and at a later time traded to the numerous secondary production centres distributed throughout the Roman Empire. This mainly centralised system allowed glass not only to be distributed efficiently but also to it kept the primary production centres close to where the raw materials (sand and natron) could be sourced resulting in a relative standardisation of the final composition.

The connection between primary and secondary workshops located in early medieval Western Europe has not been fully explored because few comparable analytical data sets (especially trace elements) have been published for Western European glass dated from the seventh century CE onwards. Moreover, the impact that secondary glass-working centres had on modifying the original base composition, including recycling, has not been fully investigated.

Previous studies suggest that recycling was greatly impacting glass production in the Italian Peninsula (Mirti et al. 2000, 2001; Uboldi and Verità 2003; Silvestri and Marcante 2011; Schibille and Freestone 2013). Recycling of “old” natron glass is most likely the result of a restriction on the supply from the primary area of production. This seems very plausible, but the nature and the role of glass in the economy needs to be addressed further, by characterising compositionally both natron and plant ash compositions traded in Northern Italy. This will help to better understand the circulation of “old” Roman natron glass versus the other compositions of a more recent production. As a result of trace elements analysis becoming increasingly more common (Henderson et al. 2016; Cholakova et al. 2016; Phelps et al. 2016; Schibille et al. 2016a, b; Ceglia et al. 2017 amongst others) it should be possible to investigate this further. A key question is, was the glass traded and worked in Northern Italy more similar to old natron glass already circulating in the Northern Italian territory such as at Aquileia (Gallo et al. 2014) and Classe (Maltoni et al. 2015) or was it indeed fresh glass imported from contemporary production areas such as Apollonia or Bet Eli’ezer (Phelps et al. 2016)?

The reasons for such a shift in composition have been attributed to the decline in the availability of natron in the Levant (Henderson 2002; Whitehouse 2002; Shortland et al. 2006; Henderson et al. in press) due to both long and short-term factors (political instability in the Delta region, discontinued trade, climate fluctuation and the rise of the Abbasid caliphate) which led to Egyptian primary production facilities stopping by the ninth century CE. Since the eighth century, at the same time this shift was occurring, the occurrence of plant ash glass is also apparent in Northern Italy (Verità and Toninato 1990, Verità et al. 2002; Uboldi and Verità 2003, Andreesu-Treadgold and Henderson 2006; Silvestri and Marcante 2011), but unfortunately, no further detailed characterisation of this material has been done till now.

The presence of plant ash glass and its mixing with natron glass has only been discussed in terms of possible tesserae production in Constantinople for use at Torcello (Andreescu-Treadgold and Henderson 2006); mixing of the glasses in Constantinople has been suggested. Does the contemporaneous introduction of plant ash glass in Italy and the Middle East mean that there was a direct trading connection between Northern Italy and the Middle East?

In order to move the debate forward concerning Late Antique and Early Medieval glass production and use in Italy, in this paper we present new scientific analyses and interpretations for glass from the secondary production site of Comacchio, Italy using electron probe microanalysis (EPMA) and laser ablation-inductively coupled plasma mass spectrometry (LA-ICP-MS). Firstly, the compositional nature of Comacchio glass will be discussed. Secondly, these results will be compared with coeval Northern Italian materials and with well-dated glass materials from primary production areas. This will make it possible to test hypotheses about the provenance of each recipe worked in Comacchio between the seventh and eleventh century CE and potentially to link the Northern Italian area with the Levant through production models and glass trade. The impact of recycling on the original “base” recipes will also be assessed.

Archaeological context and samples

Archaeological context

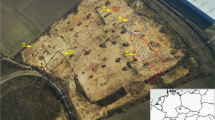

The site of Comacchio is located in the northern part of the Italian Peninsula (Fig. 1): on one side Comacchio faces the Adriatic Sea (and therefore is connected to the Mediterranean) and to the other, it is connected to the Po Plain by a widespread river network. Its borderline location was key to its commercial success (Gelichi 2017). The role of Comacchio as a key Northern Italian trading centre is clearly stated in the Liutprand capitulary (Montanari 1986), an eighth century port tax that offers indirect evidence of the type of goods that were available at the site at the time (Gelichi 2017): in addition to local goods, the people of Comacchio had access also to non-local products (such as oil and garum), potentially even some of oriental origin (such as pepper). Ceramics give indirect evidence for trade from southern Italy and the eastern Mediterranean to Comacchio: a flat-bottomed unglazed ware of local production specifically made for river transportation (Negrelli 2012) is almost exclusively associated with globular amphorae in deposits from the eighth and part of the ninth century in Comacchio (Gelichi 2017).

The importance of Comacchio as a Late Antique and Early Medieval trading centre is also demonstrated by the recovery of the port structures and warehouses of Villaggio San Francesco (80.000 m2), Comacchio’s dedicated harbour area, which became a transfer point between the inland Po Plain waterways (towards Pavia and Milan) and the Adriatic/Mediterranean Sea routes (Gelichi 2012; Gelichi 2017).

An Italian archaeological team under the scientific direction of Professor Sauro Gelichi from Ca′ Foscari University of Venice, and Dr. Luigi Malnati, from the “Soprintendenza dei Beni Culturali dell’Emilia Romagna” investigated the area beside the Cathedral of San Cassiano (DMS 44°41'44.8"N 12°10'53.7"E; Comacchio Cathedral and Piazza XX Settembre) containing the remains of a craft workshop with both evidence of metal and glass-working. Two preliminary reports have been published since then (Gelichi et al. 2008; Gelichi 2009); followed by two more reviews in recent years (Gelichi et al. 2012; Gelichi 2017). The workshop was a significantly sized building (8 × 4 m, c. 120 m2) combining wooden elements with brickwork and foundations made from brick rubble (Fig. 2). Four chronological phases were identified between the sixth to the eleventh centuries CE for the building (Gelichi et al. 2012), but the workshop was active only between the second half of the seventh and the beginning of the eighth centuries CE (Gelichi 2017, 155).

The presence of a kiln together with many vessel fragments, glass-working debris, glass-working crucibles with molten glass attached to their base, leave no doubt that at least glass-working had occurred in the workshop. After this period, the kiln was not in use: glass-working activities might have been moved elsewhere to supply material for the building of the new cathedral but, at the moment, there is no evidence where (Gelichi et al. 2012). During the eighth century, a substantial reorganisation of the area occurred: all the workshop’s activities ceased, and the area was converted into a cemetery. In the same period a church and a palace, possibly connected with the presence of a bishop, were erected alongside the cemetery.

Samples

Eighty-nine samples chosen for this study are dated between the first half of the seventh to the eleventh century CE. Given that Comacchio was a secondary production site, for most of the samples (n = 77), it was possible only to give a basic typological classification (see Fig. 3), while 12 out of 89 are undiagnostic fragments. In Fig. 4, a diagram illustrating the relationship between chronology and typology in the Comacchio dataset is shown. According to Gelichi (2017, 155), it is not possible to establish with certainty when and for how long the workshop was active, but a range of seventy years (second half of the seventh to the first quarter of the eighth century CE) has been suggested. It is evident that not all samples belonged to the active phase of the workshop: only a group of seven samples falls within this chronological range.

Chronological phases (stratigraphical unit) vs object type in Comacchio–Piazza XX Settembre glass. Full chronology is reported in Appendix A

The rest of the samples are instead dated to the phase pre-dating this one (first half to middle seventh century CE, n = 56) and some are contemporary with the construction of the Early Medieval Church (eighth century into ninth century CE, n = 18). Only eight samples date to the later phases (nineth and eleventh centuries CE). Twenty glass fragments associated with glass-working activities (wasters or crucibles) are dated to before the active phase of the workshop. On the other hand, ten fragments from the same typological group are dated to the later phase (Fig. 4); most likely these are residual fragments from the workshop activity since no other glass-working structure has been found dating to after the first quarter of the eighth century CE. Alternatively, these fragments could be imported vessels.

The full dataset description and typology is reported in Appendix A. The majority of Comacchio fragments are blue or green coloured (n = 63, different hues). The remaining are olive green (n = 5), dark blue (3), colourless (n = 7), yellow (n = 3), and light grey (n = 2). Only Com96, a goblet fragment, is decorated with multiple trails of white glass. Four samples (wasters, tesserae, and crucible layer) are opaque red and only two are opaque white (one tessera plus a decorative filament).

Methods

EMPA

The standard protocol for EMPA analysis described in detail by Henderson (1988, 78–79) was followed in this study. Analysis of a selection of Comacchio samples fragments of 1–2 mm was performed using a JEOL JXA-8200 electron microprobe then in the Microanalysis Research Facility of the Archaeology department of Nottingham University, UK. The system is equipped with four wavelength-dispersive X-ray spectrometers with LIF, TAP, PETJ, and LIFH crystals, a single energy-dispersive X-ray spectrometer and both secondary- and backscattered detectors. The remaining samples from Comacchio were analysed with a Cameca SX100 microprobe located at the Open University.

Carbon coating was applied to the polished surface to prevent localised charging and any resulting distortion and deflection of the electron beam, as suggested by Henderson (1988). Three analyses were carried out on each sample at a 20-kV accelerating voltage and a 50-nA incident beam current with a 50-μm defocused electron beam. A defocused beam is used to reduce the effect of the migration of alkalis and other volatile elements within the samples. The counting time was 30 s on the peak (20 s for sodium) and 20 s on the background (10 s for sodium). The EPMA-WDS was calibrated against a series of certified minerals, pure metal, and synthetic standards. Analytical results were corrected using a commercial ZAF program for the matrix. Results are reported in Appendix D. In total, 26 elements were determined: sodium, copper, titanium, zinc, aluminium, iron, calcium, tin, arsenic, manganese, antimony, nickel, magnesium, chlorine, potassium, cobalt, barium, lead, sulphur, chromium, vanadium, silicon, zirconium, phosphorus, and strontium.

Accuracy and precision of both sets of analyses have been checked by comparing them with Corning B standard analyses, which was analysed at the start and at the end of each analytical session, for a total of ten for the first set of analyses, and twenty-two for the second set. Averaged values for Corning B and our measured values plus accuracy and standard deviations are reported in Appendix B for both sets of analyses, together with the standard deviation for each element. The precisions of SiO2, Al2O3, Na2O, K2O, CaO, MgO, FeO, MnO, and CuO are ideal (RSD < 5%). For minor elements, the RSD is above 5% but below 20% aside from V2O5 in the first set. In the second set, the precision of all aforementioned major oxides is ideal (RSD < 5%), except TiO2. For minor elements, the RSDs are above 5% but below 20%, apart from SnO2, BaO, NiO, CoO, and V2O5.

For the majority of oxides, the measured value was within 20% of the quoted value for both the first and second sets of analyses, and most are much lower, and therefore the values can be considered acceptable. Overall, for four oxides (PbO, BaO, V2O5, and SO3) the error was in excess of this level and these results have to be considered as a semi-quantitative; BaO and V2O5 were close to minimum levels of detection or not detected. The following elements were sought but not detected in the first set: SnO2 and As2O5.

LA-ICP-MS

A total of sixty-two samples were selected for LA-ICP-MS analysis based on three parameters: chronology, artefact type, and colour. The same blocks as prepared for EMPA were used for LA-ICP-MS analysis. Prior to LA-ICP-MS analysis, the carbon coating was cleaned off the blocks by rubbing a tissue soaked in dilute acid over the surface for a few seconds. The laser ablation unit was a NewWave (Electro Scientific Industries, Inc.) UP193 nm excimer system. The sample was placed in a two-volume ablation cell with a 0.8 L min−1 He flow. In addition to the sample block, NIST glass standards SRM610 and 612 were placed in the chamber. The laser was normally fired at 10 Hz for 45 s using a beam diameter of 75 μm. Fluence and irradiance as measured by the internal monitor were typically 3 J/cm2 and 0.85 GW/cm2 respectively. Prior to introduction into the ICPMS the He flow was mixed, via a Y-junction, with a 0.85 L min−1 Ar and 0.04 L min−1 N2 gas flows supplied by a Cetac Aridus desolvating nebuliser. The Aridus allowed introduction of ICPMS tuning solutions and optimisation of the Aridus sweep gas (nominal 4 L min−1 Ar). During solid analysis by the laser, the Aridus only aspirated air. The ICPMS used in this study was an Agilent 7500cs series instrument. Data were collected in a continuous time resolved analysis (TRA) fashion, the dwell time for each of the 47 isotopes was 30 ms, giving a time interval of 1.5 s for each sweep. Prior to laser firing a period of at least 120 s of ‘gas blank’ was collected, then 3 ablations being made on the SRM610; 3 ablations on the SRM612; 3 ablations on each sample and finally 3 ablations on the SRM610. The SRM610 was used to calibrate the system whilst the SRM612 was used as a quality control (QC) material; aggregated results for each element-isotope concentration are given in Appendix B. Quoted values of NIST SRM612 are presented in Appendix B (two analytical sessions). Data reduction was performed using “Iolite” v2.5 LA-ICP-MS software and any subsequent calculations in Excel spreadsheets. Calculated and relative standard deviations are presented to check the precision and accuracy of the measurements, which appears to be sound: the precision of most elements is good for both sessions (< 5 RDS%), while the accuracies for all the elements ranged between − 2 and + 1%, which are considered within the range of quantitative results.

Results

This section has been divided into three parts to better discuss the EMPA and LA-ICP-MS results. In the first part, Comacchio compositional patterns will be discussed in light of major, minor, and trace element data together with comparisons with other known 1st-millennium glass compositions. Secondly, the impact of recycling and mixing processes over the Comacchio glass groups will be discussed by looking at specific recycling (Co, Cu, Sn, and Pb) and other trace elements markers. Finally, the production and circulation of glass after the seventh century CE in Northern Italy will be discussed in light of these results. When not specified, results are reported as averaged values.

Glass classification and raw materials

Electron Microprobe and trace elements results are given in Appendix D. The compositions here described are typical of the glass production of the 1st millennium CE, where SiO2, Na2O, CaO, and Al2O3 are the most characteristic major and minor element oxides. Based on K2O and MgO contents (Fig. 5), the majority of samples analysed are natron-type soda-silica-lime glasses, typical of the 1st millennium CE (low potassium and magnesium oxides < 1.5 wt%).Only three samples (Com21, 22, and 23) with higher contents of both oxides (> 2.2 wt%) being classified as plant ash glasses.

A small group of samples (n = 13, 1 mosaic tessera, one goblet, and the rest either wasters or crucibles layers) shows relatively higher contents of either K2O or MgO (respectively over 1.5 wt% and 2 wt%), which suggests the incorporation of contaminants from the fuel ash (Paynter 2008). The relatively higher MgO content (< 2 wt%) in three red opaque natron samples (Com38, 92, and 94) can be justified if we suggest the presence of a reducing agent, such as charcoal (Henderson 1991 Boschetti et al. 2016, 309). One white tessera (Com91) shows elevated MgO content (3.93 wt%). Higher MgO contents paired with low K2O in opaque white mosaic tesserae is not unusual (Henderson 1991); it has been suggested that plant ash could have been used to make the base glass, or potentially the addition of plant ash to natron glass (Boschetti et al. 2016, 308).

A plot of Fe2O3/Al2O3 and Fe2O3/TiO2 has been used to highlight the differences in sand sources in natron glasses and to discriminate HIMT from Foy-2 groups together with comparative data (Fig. 6). The same plot has been used with success in the past (Ceglia et al. 2015).

Fe2O3/TiO2 against Fe2O3/Al2O3 ratios for (A) Comacchio glass by assigned compositional group and (B) comparative data from Foy et al. 2003, Schibille et al. 2016b; Ceglia et al. 2017—non-recycled data. All the major groups separate except for the “intermediate” composition which falls between the Levantine and Foy-2 samples

Based on major, minor, and trace elements, six groups have been identified: two different types of Levantine glass, Foy-2, plant ash, HIMT, and a mixed natron-based composition (here classified as “intermediate”).

To discriminate between the samples, we present three markers associated with the sand and lime sources (Fig. 7A, B), Ceglia and co-workers recently used the same markers to discriminate between their compositions in Late Antique glass from Cyprus (Ceglia et al. 2017). Zr, Ce, and La concentrations are all markers for the different silica sources used in first-millennium glass. The ratio of Sr and CaO describes the carbonate (shell, etc) fraction introduced through sand in natron glass and plants in plant ash glasses. It should be mentioned that manganese-bearing minerals also contribute to the final strontium concentration (Meisser et al. 1999; Gallo et al. 2014).

(A) Zr/SiO2 vs. Ce/La ratios by assigned compositional group to investigate the silica source; (B) Zr/SiO2 vs. Sr/CaO ratios to investigate the lime component in Comacchio glass–Piazza XX Settembre. Both ratios reveal the mixed nature of the intermediate compositions since almost all samples fall between the range of Foy-2 and Levantine A and B group

In Figs. 8 and 9, the trace elements patterns for natron groups normalised to the upper continental crust composition (Kamber et al. 2005) are given. Table 1 summarises the compositions of what we consider to be “pristine” or not recycled glasses presented in this work together with comparative data from different sources. Recycling and mixing processes will be discussed in the “Recycling and mixing section”. Individual sample results are shown in Appendix D.

Levantine–Apollonia type (Levantine A, n= 12) and Jalame type (Levantine B, n = 5)

Originally used by Freestone and colleagues (Freestone et al. 2000) to indicate, ‘Levantine I’, more recently it has been suggested as a term to describe the production area of the Levant (Phelps et al. 2016). At the same time, it has been suggested that the name of the production site should be used to differentiate between similar sub-compositions (e.g. Apollonia vs. Jalame type). In this paper, we will follow these guidelines. Levantine glass is characterised by high silica sand with high feldspar and minimal other minerals introducing low Fe2O3, TiO2, and Zr values and high Al2O3. In the same glass, CaO contents of over 7 wt% positively correlated with high Sr concentrations (> 400 mg/kg) suggests that lime added to the melt in the form of shells present in coastal sands rather than in limestone (Wedepohl and Baumann 2000; Freestone et al. 2003). Na2O/SiO2 vs. CaO/Al2O3 ratios (Fig. 10) can help in distinguishing two main Levantine groups, Levantine A (n = 12) and Levantine B (n = 5), which includes almost all blue-green Comacchio samples save for one olive green and two colourless samples (Com34, Com59, and Com60 respectively).

Na2O/SiO2 vs. CaO/Al2O3 bi-plot demonstrating (A) the separation between Levantine, HIMT, and plant ash groups; (B) the separation between Levantine groups Levantine A and Levantine B in Comacchio glass. The two Levantine groups show different Na2O/SiO2 ratios, which suggest the use of different raw materials and potentially different primary production centres. Comparative data from the three known primary production sites sixth–seventh century Apollonia (Phelps et al. 2016) and fourth century Jalame (Brill 1988)

The two groups can be differentiated according to their Na2O/SiO2 ratios (respectively ≤0.22 and ≥ 0.25). CaO/Al2O3 ratios are also different in both groups (respectively 2.90 < and > 3.04), save only for Com15 and Com76 that shows a much higher ratio (3.49) compared to the other Levantine A samples and for Com16, which instead shows a lower one (2.55). Levantine A–Apollonia-type samples are dated from the first half of seventh century–early ninth century CE while Levantine B–Jalame type instead from the first half to the middle seventh century AD CE.

Both trace element–major oxide patterns show that the two groups are very closely related geochemically (Fig. 8B), with Levantine B showing overall higher trace element values, of Sr and V in particular that indicates the use of a different sand source. A difference in the average boron concentrations in both groups confirms what is already evidenced in Fig. 8B, that a different soda source (natron in this case) has been used to produce Levantine A (47.53 mg/kg) and B (81.54 mg/kg).

We can therefore state with confidence that both groups were made indeed in glass workshops located in the Levant with sand sourced from the same area, but that slightly different sources of natron and sand were used. When we compared both groups with other known Levantine compositions (Table 1), Levantine A is geochemically similar to Levantine Apollonia type produced in the Levant between the sixth and the seventh century CE (Freestone et al. 2000; Phelps et al. 2016) while the Levantine B composition is close to Jalame glass first recognised by Brill (Brill 1988) with overall higher soda (17.03 wt%), alumina (3.24 wt%), and lime (10.13 wt%) contents. Moreover, Levantine B is also similar with AQ2b Levantine low MnO glass found at Aquileia (Table 1) also dated to an earlier period (Gallo et al. 2014).

HIMT (n = 2)

Two samples (Com74 and Com75), both dated to the eighth–early ninth century CE, can be classified as HIMT (high Iron, Manganese, and Titanium) glasses as described for natron glass from Carthage (Freestone 1994) because of its lower lime content (5–6 wt%) associated with higher percentages of soda, iron, manganese, and titanium oxides. Over time, different names have been given to this glass type mainly produced between the fourth–seventh century CE (Foy et al. 2003; Foster and Jackson 2009; Ceglia et al. 2015; Ceglia et al. 2017). The origin of HIMT glass is still debated. The use of a sand rich in impurities linked with a non-marine source of lime (such as limestone) suggests Egypt as a potential area of production (Freestone et al. 2005). Its higher soda levels compared to Levantine glasses, has also been linked to a primary production workshop closer to Egyptian natron sources (Freestone et al. 2005; Nenna 2014). Recently Nenna (2014) suggested that HIMT could have been produced on the Mediterranean Sinai coast, but the precise workshops locations are not known. Both Com74 and Com75 have high MnO (2.26 wt%), Fe2O3 (2.25 wt%), TiO2 (0.56 wt%) contents along with low CaO (5.19 wt%) typical of HIMT glasses. In addition, Comacchio HIMT glasses also have overall high concentrations of trace elements, and in particular of V (65.45 mg/kg), Cr (72.18 mg/kg), and Zr (265.03 mg/kg). Both samples are olive green coloured. As seen in Table 1, Comacchio HIMT glass compositions are very close geochemically to other known HIMT compositions such as Foy-1 (Foster and Jackson 2009), HIMT/HIT (Schibille et al. 2016b) and HIMTa (Ceglia et al. 2015, 2017), but most of it with AQ1a third–fifth century glass material from Aquileia (Gallo et al. 2014).

Foy-2 (n = 4)

The Foy-2 group includes two compositions labelled originally by Foy and colleagues as Foy-2.1 and Foy-3.2 (Foy et al. 2003) produced between the fifth and seventh century CE: Foy-2.1 is dated to the sixth–seventh century CE while Foy-3.2 instead to the fifth century CE (Foy et al. 2003; Gallo et al. 2014; Maltoni et al. 2015; Cholakova et al. 2016; Schibille et al. 2016b; Ceglia et al. 2017). Even though they share numerous compositional similarities with the HIMT group, in recent years there is a general consensus that these two major compositions do not share the same geochemical origin based on a lack of correlation between Fe2O3, TiO2, and MnO concentrations and higher CaO and lower TiO2 concentrations when compared with HIMT glasses (Freestone et al. 2008; Gallo et al. 2014; Ceglia et al. 2015; Schibille et al. 2016a, b).

Four samples from the Comacchio dataset, three vessels (yellow) and one mosaic tessera (colourless), dated between the first half of the seventh and the tenth century CE can be classified as Foy-2, and more specifically to the 2.1 variant (Appendix D; Table 1). Comacchio Foy-2 is clearly separated from Levantine compositions based on its lower CaO (7.89 wt%) and higher Na2O (17.33 wt%), Al2O3 (2.60 wt%), Fe2O3 (1.26 wt%), and TiO2 (0.12 wt%) contents paired with higher Sr (696.22 mg/kg) and Zr (78.74 mg/kg) concentrations. The trace element patterns confirm an overall enrichment in trace elements such as V (35 mg/kg), La (8.91 mg/kg), Y (8.79 mg/kg), Cr (15.66 mg/kg), and Ba (413.79 mg/kg). The Comacchio Foy-2 average composition falls within the compositional range of several other Foy-2 glass fragments (Table 1) but in particular with both Foy-2.1 raw glass (Foy et al. 2003) and Foy-2 Byzantine glass weights (Schibille et al. 2016b).

Plant ash (n = 3)

Plant ash glass is characterised by higher MgO and K2O content and sometimes lower Al2O3 contents suggesting the use of crushed quartz pebbles or low-alumina sand as a SiO2 source (Henderson et al. 2004). As anticipated previously, three beaker fragments (Com21, Com22, and Com23), all dated between the tenth and eleventh century CE have both K2O and MgO values over 2.0 wt% paired with high P2O5 (0.28 wt%) and MnO over 1 wt%; these all being characteristics of plant ash glass reintroduced in the post-Roman period as illustrated by the eighth–ninth century CE industrial centre at al-Raqqa, northern Syria (Henderson et al. 2004).

Comacchio plant ash group is geochemically similar to both eleventh century CE plant ash groups from Raqqa (Henderson et al. 2004) and Tyre (Freestone 2002), and it is distinct from eighth–ninth century CE Raqqa plant ash glass because of its lower Na2O (11.25 wt%) and higher CaO (10.53 wt%) contents (Table 1).

Trace elements have been used recently to address the area of production of Islamic plant ash glasses from different regional production zones in the Levant, northern Syria, and in Iraq/Iran (Henderson et al. 2016) forming a decentralised production system. In addition to entering the glass via contaminant heavy minerals in the sand source, trace elements can enter the melt via the plant ash source, i.e. Li, Rb, and Cs substituting for K and Na in feldspars. Henderson et al. 2016 have also demonstrated clear discrimination between Levantine and non-Levantine (Northern Syria Iraqi and Iranian glasses) production based on both sand (Cr and Fe) and plant ash (Li, Cs, and K) markers for plant ash glass.

Comacchio Cr and Fe concentrations are presented in Fig. 11 together with comparative data from the eighth to the fourteenth century CE plant ash glass from the three production areas identified by Henderson and colleagues (Henderson et al. 2016). The Eastern samples have more Cr for a given amount of Fe compared with the Western ones. Based on these two sand markers, Comacchio plant ash glasses plot consistently in the Levantine plant ash area: they contain higher Fe concentrations (5448.67 mg/kg) compared with values of Cr (11. 98 mg/kg) together with all the other Levantine Islamic plant ash (Fig. 11).

Trace elements concentrations and ratios in plant ash glasses in Comacchio Piazza XX Settembre, comparison data after Henderson et al. 2016. (A) Fe vs Cr concentrations. (B) LI/K vs Cs/K ratios. C4 group plots consistently with glass from Beirut, Damascus, and Khirbat al Minya

Variations in Li/K ratios are determined by the local geodiversity: the Anti-Lebanon, Taurus, Zagros, and Elbrus mountain ranges contribute contribute to the geochemistry of rivers rivers such as the Barada, Euphrates, and Tigris; the Nile will influence the geochemistry of the Southern part of the Levantine coast (Henderson et al. 2016, 139). When Li/K and Cs/K ratios are considered, the same pattern as Fe-Cr is observed: Comacchio plant ash glasses show overall a lower Li/K ratio paired with variable Cs/K, consistent with the Western plant ash glass contrary to Eastern and Raqqa glasses that show instead an increase in the same ratio (Fig. 11). Considering their similarities in major, minor, and trace elements (Table 1; Fig. 11), Comacchio plant ash glasses produced at the primary glass-making site of Tyre (Lebanon), also included in the Western area of production (Henderson et al. 2016).

Intermediate composition (n = 63)

The largest group of samples in Comacchio glass (n = 63) is dated to the entire chronological span of glass samples (first half of seventh–eleventh century CE). It includes samples of different shades of blue-green (n = 50) dark blue (n = 4), colourless (n = 4) and all the red opaque samples (n = 5). The base glass of this group is similar to that of the Foy-2 compositional group, with higher Fe2O3 (1.24 wt%), TiO2 (0.12 wt%), MnO (0.68 wt%) paired with CaO (c.7 wt%), Al2O3 (c.2.68 wt%), and Na2O (c.17.49 wt%) when compared with the Levantine compositions (Table 1). If both Na2O/SiO2 and CaO/Al2O3 ratios are considered, there is some overlap between the intermediate composition and Levantine B groups that has an overall higher Na2O content compared with Levantine A (Fig. 10).

When Fe2O3/Al2O3 and Fe2O3/TiO2 ratios are taken into account (Fig. 6), both Levantine A and B groups separate from HIMT and Foy-2 glasses. On the other hand, the intermediate composition shows a variable range of both ratios (Fe2O3/Al2O3, 0.14–2.79, Fe2O3/TiO2, 3.47–47.28), which partially falls within the Foy-2 and partially between the latter and the Levantine composition.

Trace element patterns also confirm the hypothesis that the intermediate group is of mixed origin, falling in between Levantine and Foy-2 groups, with higher concentrations of V (21.94 mg/kg), Cr (22.80 mg/kg), Zr (65.86 mg/kg), and Hf (1.61 mg/kg).

Recycling and mixing processes

Many publications show that recycling was a common activity during Roman and Early Medieval times both in the Italian peninsula (Silvestri 2008; Silvestri et al. 2008; Silvestri and Marcante 2011; Schibille and Freestone 2013) and in the Mediterranean area (Jackson 2005; Duckworth et al. 2016; Jackson and Paynter 2016; Schibille et al. 2016a; Ceglia et al. 2017). Despite the recognition of recycling as a pervasive phenomenon in 1st millennium glass production, there is no clear list of criteria to help identify such practices. It is generally agreed that the presence of certain elemental markers (Co, Zn, Sn, Cu, Sb, and Pb) between 100 and 1000 mg/kg can be regarded as indicators of recycling. Below 100 mg/kg concentrations, glass was supposedly not recycled. In addition, the presence of both decolourisers Mn and Sb at the same time is also recognised as sign of recycling (Jackson 2005). To make glass colourless, Romans were using both Sb2O5 and MnO but there is no evidence for the addition ofboth to the same batch at the primary stage (Freestone 2015, 31); only that both compounds were introduced during recycling (Jackson 2005).

In Fig. 12, both recycling markers and decolourisers concentrations for each of the six main compositions (including the intermediate group of mixed based glass) have been plotted. The main criterion to distinguish non-recycled from recycled glass is the combined presence of recycling markers and both decolourisers for each composition. Levantine A and B show the overall lowest concentrations of recycling markers (Fig. 14) similar to concentrations assigned to Levantine I–Apollonia glass by Freestone and colleagues (Freestone et al. 2002, table 3, 267). Despite Both Levantine compositions having slightly higher MnO concentrations (117 and 145 mg/kg respectively), they still fall within the values of potentially non-recycled glass from the literature: the composition of five raw chunks from Apollonia recently analysed by Phelps et al. 2016) have an average MnO concentration of 191 mg/kg while non-recycled Levantine I from Cyprus (Ceglia et al. 2017) has 139 mg/kg.

The plant ash glass analysed here also has low concentrations of all markers with the exception of Pb (97.22 mg/kg), which is higher when compared with the majority of plant ash glass Pb concentrations (Henderson et al. 2016, 145–6), but still below 100 mg/kg and therefore within the limits of non-recycled glass. Both HIMT and Foy-2 compositions have higher values in of all recycling markers, but still within or just above the 100 mg/kg limits (Fig. 14). Comacchio HIMT glass has lower Pb values (51.4 mg/kg) and Co (15.8 mg/kg) and similar Cu concentrations (89.2 mg/kg) when compared with the ‘verre brut’ Foy 1 (Foy et al. 2003, 83). Therefore, we can suggest that Comacchio HIMT does not show evident signs of recycling.

The average Foy-2 recycling marker values for Foy-2 in Comacchio glass is Co 9.6 mg/kg; Cu 68.8 mg/kg; Sn 13. 8 mg/kg; Pb 78.2 mg/kg. It is possible that Foy-2 has gone through moderate re-melting cycles since it contains above 100 mg/kg of both decolourisers (Sb 146.66 mg/kg; Mn 11,452.50 mg/kg). Supposedly non-recycled Foy-2 (Ceglia et al. 2017) also shows the occurrence at the same time of both decolourisers: if Foy-2 from Comacchio has indeed been re-melted, it has not been continuously recycled for a long period of time.

The intermediate composition shows concentrations of Co, Cu, Zn, Sn, and Pb significantly over 1000 mg/kg (Fig. 12), which indicates that such glass has undergone through repetitive recycling of glass involving different base compositions.

There is no clear way of establishing if mixing processes have occurred during glass-working but there is a general agreement that, when two or more glass compositions are mixed together, the result of this mix will be recognisable graphically because it lies directly between the two original end-members (Henderson et al. 2004, 451, 465; Freestone 2015, 29). A similar effect can be seen in Fig. 6 where the intermediate compositions fall on a mixing line of Fe2O3/Al2O3 and Fe2O3/TiO2.

Save the red opaque samples, which contain higher iron oxide (Fe2O3 > 2.0 wt%) introduced into the melt as a reducing agent to produce the red colour in the glass (Barber et al. 2009, 124), some potentially contaminated samples from the crucible with higher Al2O3 and Fe contents show an increment of both ratios (0.60 wt% and > 15 respectively). Experimental work by Paynter and co-workers (Paynter 2008) has shown that, during re-melting, glass absorbs different contaminants from clay crucibles or furnace linings such as aluminium, titanium, potassium, and iron oxides, hence the higher Fe2O3/Al2O3 and Fe2O3/TiO2 ratios. This will be particularly true when secondary workshops re-melt small quantities of glass in small crucibles, due to high crucible surface area to glass volume ratio. The contamination of fuel ash in intermediate compositions is reflected in the higher P2O5 values (c. > 0.10 wt%) which is higher than other Comacchio glass excluding the plant ash group, which are naturally richer in phosphorus (Henderson et al. 2004, Table 2, 453).

The mixed nature of the intermediate composition is clear in Fig. 7. Comacchio non-recycled compositions Levantine A, B, and HIMT separate well when all three ratios are considered (Table 2). Levantine A and B fall within both Levantine I non-recycled average ratios (Ceglia et al. 2017) for all markers: 0.61/0.70 for Zr/SiO2, 1.88/1.92 for Ce/La, and 49.19/47.74 for Sr/CaO respectively. Comacchio HIMT glass displays higher ratios values in all three markers (4.16 Zr/SiO2, 1.76 Ce/La, and 83.07 Sr/CaO respectively), but still in line with the non-recycled HIMTa average ratios suggested by Ceglia and co-workers (3.52 Zr/SiO2, 1.79 Ce/La, and 72.83 Sr/CaO respectively). The same can be said for the Foy-2 group except for one sample (Com85), which shows a much lower Ce/La ratio (1.29) when compared with the other three (1.56, 1.61, 1.77) and the average non-recycled Foy-2 ratio from Ceglia (1.68). Even though the content of Fe2O3 is higher in Com85, we decided not to classify it within the Foy-2 sub-group with a higher iron content described recently in the literature (Schibille et al. 2016b; Ceglia et al. 2017) because its iron oxide content still falls within the normal Foy-2 glass type (1.78 wt%).

The intermediate composition falls within Comacchio non-recycled groups Levantine (A and B) and Foy-2 with average ratios of ZrSiO2 (0.70) Ce/La (1.92) Sr/CaO (47.9) respectively. Moreover, the same group falls on a clear dilution line in Fig. 7B. We suggest therefore that Comacchio intermediate glass is the result of mixing heavily recycled glass with fresh non-recycled glass (Levantine A and B) or (Foy-2) glass with limited recycling. A similar hypothesis has been suggested for Nogara natron glass (Silvestri and Marcante 2011, 2517), which also falls close to the same range for all three makers values (1.12 Zr/SiO2, 1.75 Ce/La, and 64.7 Sr/CaO average ratios respectively).

Mixing between plant ash and natron glasses also occurred at Comacchio, albeit limited with certainty to few fragments. In Fig. 13, a plot of K2O and P2O5 is shown. Many of the intermediate samples showing relatively high contents of P2O5 (0.17 wt%) compared to the Comacchio sample assigned to non-recycled natron groups (Levantine A 0.09 wt%, Levantine B 0.12 wt%, Foy-2 0.12 wt%, HIMT 0.06 wt%). Increase in P2O5 in natron glass here may be linked with contamination from alkali-rich gases from repetitive melting cycles in the furnace (Paynter 2008, 290).

K2O vs. P2O5 bi-plot in Comacchio glass groups. Two clear dilution lines between the plant ash group and some Levantine A and intermediate composition samples demonstrates that limited mixing between natron and plant ash group was occurring. Moreover, most of the intermediate group show P2O5 > 0.10 wt%, which clearly indicates contamination from fuel ash (Paynter 2008)

Also in Fig. 13, a few samples from Levantine A (Com76 and 79) and the intermediate group (Com63, 36, 40) fall on one dilution line with the plant ash group: the intermediate samples date close to the period where the Comacchio furnace was active (first half of the seventh to the end of the eighth centuries CE) while the plant ash glass (tenth–eleventh century CE) and two Levantine A fragments (eighth century into ninth century CE) on the other hand belong to the later phase of the excavated area. One of the intermediate samples, Com14, also shows a high content of both K2O and P2O5: given its high Na2O content, we suggest that this sample might be a plant ash sample adulterated with a small quantity of natron glass.

Overall we suggest that the plant ash group was either imported and introduced in the melt during an earlier phase when the workshop was active (and therefore it would be residual glass) or that a similar plant ash composition was re-melted and mixed with natron in the workshop.

The Comacchio Workshop: Recycling or import of fresh glass?

From the data presented in this paper, a clear pattern emerges. First, we need to consider the relationship between the archaeological context, compositional groups, and chronology in the Comacchio dataset. As shown in Fig. 14, most of samples belong to the workshop area (80 vs. 9 samples respectively). On the other hand, 82 out of 89 samples (including wasters and glass-working indicators) are dated before or after the suggested active period of the excavated furnace, the second half of the seventh to the first quarter of the eighth century CE (Fig. 4).

Therefore, especially for the later phases, we cannot say with confidence that the glass was reworked at the furnace, but we can hypothesise that either another workshop was operating in the area (although there is no evidence for this) or that they could be residual from the workshop phase. This does not include vessel fragments, which might represent glass imports or stored cullet ready to be traded to or re-melted at another workshop.

With these factors in mind, one pattern emerges: both analytical results from Comacchio and comparison with other known compositions from the literature (Table 1) shows that both “old” and new compositions were circulating at Piazza XX Settembre between the early seventh and the eleventh century CE. The re-melting of the same glass composition as a sign of continuity of circulation has already been highlighted in the literature. For the natron glass from Nogara, the heavily recycled glass did not allow a closer comparison with recent data (Silvestri and Marcante 2011, 2516). Uboldi and Verità (2003) both identify HIMT and Levantine glass in their Medieval glass from Lombardy and suggested continuity of production, but no further classification was given. On the other hand, they suggest that the intermediate composition of their samples was a mixture of natron and plant ash glass and might be evidence for continuity of production and recycling throughout the natron-plant ash transition period. Mixing between plant ash and natron glass in Comacchio material is limited to very few samples (Fig. 13) but can also be considered evidence for continuity of production.

Moreover, the Comacchio intermediate composition is also the result of continuous recycling of the same type of glass (Fig. 12) and of natron glass with natron glass mixing (Fig. 7); the presence of this intermediate composition for the whole dataset and time-span (Fig. 15) is definitely proof of re-use of the same glass over a long period of time.

The same can be said for other compositions, such as Levantine B and HIMT, which shows geochemical similarities with other Northern Italian materials (AQ2b and AQ1a respectively from Aquileia and Jalame glass) in circulation since at least the fourth century CE (but potentially even older).

As demonstrated by the low concentrations (< 100 mg/Kg) of recycling markers (Fig. 12), non-recycled–pristine glass of recent production was circulating in the form of either raw glass or glass artefacts in Comacchio and potentially also in Late Antique and Early Medieval Northern Italy. This is the case for Levantine A–Apollonia type, Foy-2, and plant ash groups found in Comacchio. Despite the limited number of fragments compared with the heavily recycled ones (16 against 89 samples), the presence of pristine glass fragments still indicates some trade of fresh glass to the Italian Peninsula. Recently, Phelps and co-workers (Phelps et al. 2016) revaluated glass production in the Levant between the seventh and the twelfth century CE. From their analysis, it emerges how Apollonia-type glass dominated the Levantine seventh century production, before the natron shortage occurred (Phelps et al. 2016, 63). Since we know that Apollonia furnaces stopped producing glass by the early eighth century (Phelps et al. 2016, 63), the hypothesis that some of the same unrecycled glass produced in the Levant might have been traded to Comacchio in form of raw glass or vessels (Levantine A) becomes plausible.

There is less clarity about the production of Foy-2 glass. A great obstacle in assessing the production of Foy-2 is that glass with similar compositional characteristics has been called many different names throughout the years (Freestone et al. 2000; Foster and Jackson 2009; Rosenow and Rehren 2014; Ceglia et al. 2015). If the sixth century date assigned to this composition in the recent literature (Cholakova et al. 2016; Schibille et al. 2016a, b; Ceglia et al. 2017) is correct, Foy-2 in Comacchio might be glass produced a century before. There is no reason why Foy-2 glass could not also reach Comacchio in its unrecycled form still in the seventh century CE; as for Foy-2 from Cyprus (Ceglia et al. 2017). Unfortunately, there are no direct comparisons for the Foy-2 composition amongst published Northern Italian glass compositions.

We cannot say with confidence that plant ash glass was reworked in the Comacchio furnace given that all three samples are dated to a later period (Fig. 15). Nonetheless, if our hypothesis about intermediate sample Com14 (middle seventh century CE—goblet) is correct, this would also imply that a similar plant ash composition was indeed circulating in Comacchio very close to the active phase of the furnace. This could also mean that plant ash glass might have been used in the workshop from an earlier period. If we assume that plant ash glass was also re-melted during the period while the furnace was active, the presence of plant ash glass together with mixing practices in Comacchio as well as in other Northern Italian archaeological contexts (Verità et al. 2002; Uboldi and Verità 2003) represents an important marker for trade with the Middle East, since it was occurring in parallel with its reintroduction in its primary production areas (Henderson et al. 2004). The trading parallel with eighth century globular amphorae of Aegean production found at Villaggio San Francesco (Negrelli 2012) also ties in well within the same narrative: Comacchio was not only was a place for receiving and redistributing long-distance goods (Gelichi 2017) such as oil, wine, and spices but it might have become a crucial nodal point to import fresh glass directly from the primary production sites in the Levant such as Bari was at the time in southern Italy.

Based on the circulation of compositions in Comacchio (Fig. 15), we can suggest a production model for the workshop itself. As already remarked, it is not possible to establish with certainty when and for how long the workshop was active: given that the majority of samples belong to a phase dated before the proposed period of activity of the workshop (Fig. 4), an earlier starting date for the workshop active phase might be suggested, extending to the first half of the seven century CE.

With this in mind, we suggest that a local reserve of “old” glass must have constituted the main supply where glass-workers could source glass to re-melt in the Comacchio workshop. This practice has shown to be the case either in the form of heavily recycled cullet (Silvestri and Marcante 2011) or mosaic tesserae added to colourless glass as described by Theophilus in the twelfth century account of medieval crafts “De Diversis Artibus” (Schibille and Freestone 2013, 9). This reserve of “old” heavily recycled glass (intermediate group) was mixed with pristine glass (Levantine A–Apollonia type; Foy-2; HIMT; plant ash glass) and therefore reintroduced in the production cycle. This production model will be similar to what has already been suggested for Nogara material (Silvestri and Marcante 2011, 2516–7).

Conclusions

At least five major chemical compositions were circulating between the seventh and the eleventh century CE at the Comacchio workshop: HIMT, Foy-2, two different Levantine compositions (Levantine A and B), and one plant ash from the Levant. The sand source, soda, and feldspar markers such as Si, Na, Zr, Ce, La, Sr, and Ca proved to be the most significant variables. In addition, one natron-based composition (renamed “intermediate”), was also recognised the in Comacchio dataset: this composition differs from the other natron-based ones for its elevated concentrations of recycling markers (Fig. 12) and for its “blurred” values when compared with the other natron glass groups.

Given that most of Comacchio glass was recovered from the workshop area (Fig. 14) and it is dated to the supposed active phase of the furnace (second half of the seventh–early eighth century CE) or immediately before (from the first half of the seventh century CE onwards), we can suggest not only that most glass (n = 80) was used in the workshop but also tentatively an earlier starting date for the workshop active phase, extending to the first half of the seven century CE. For the remaining glass (n = 9), we cannot make the same claim; it consists of very few samples.

The pattern emerging from both analytical results from Comacchio and a comparison with other known compositions from the literature (Table 1) shows that both “old” and compositions of more recent production were circulating at Piazza XX Settembre between the early seventh and the eleventh century CE. The circulation of “old” glass compositions such as the HIMT type comparable with AQ1a Aquileia (Gallo et al. 2014) and Levantine B–Jalame type comparable with AQ2b from Aquileia (Gallo et al. 2014) suggests continuity of circulation in Northern Italy at least from the third century CE up to the early ninth century CE. On the other hand, in the Comacchio dataset are compositions of more recent production that were traded from the Levant and the Middle East in form of raw glass or vessels, such as non-recycled Levantine A–Apollonia-type, Foy-2, and the plant ash groups. Because of access to both the Po river network in the west and to the Adriatic Sea in the east, Comacchio and its harbour, Villaggio San Francesco, might have also easily been redistribution centres for glass trade across Northern Italy.

For the first time, the provenance of Early Medieval plant ash glass in Veneto has been discussed in a broad context by considering trace elemental compositions and by comparing them with data from the Levant, Northern Syria, and the Middle East. The plant ash group does not match with northern Syrian production such as eighth–ninth century ce Raqqa (Henderson et al. 2004, 2016), but instead matches Fe/Cr, Li/K, and Cs/K plant ash-based glass ratios from the Levantine area of plant ash glass production (Henderson et al. 2016). Given the later date of Comacchio glass samples (tenth–eleventh century AD), the primary glass-making site of Tyre could be a good match for both compositionally and chronologically for the Comacchio plant ash group but equally other production centres like Damascus could be considered. This does not exclude the trade of plant ash glass from other production areas and additional trace elements analysis from other coeval datasets will definitely help the interpretation. Trade of plant ash glass was occurring at the same time in Southern Italy: two samples from Bari (eighth–eleventh century CE) provide the first clear evidence of the import of soda-rich plant ash glass from the Islamic east to Byzantine Southern Italy (Neri et al. 2019, 258). Considering that Comacchio was also under Byzantine control, it is not unreasonable to suggest plant ash (and maybe other pristine glass such as Levantine A–Apollonia type) could also have been traded through the same routes from the Levant from at least the middle seventh century CE.

If our hypothesis concerning the circulation and reworking of glass in Comacchio is correct, all major natron glass compositions were involved in heavy recycling practices at Comacchio workshop, minus the intermediate group, for which we suggest is the result of mixing reserves of heavily recycled glass with unrecycled glass such as the other untainted group worked at Comacchio. A similar hypothesis has already been suggested for Nogara glass (Silvestri and Marcante 2011), which shows similar Zr/SiO2, Ce/La, and Sr/CaO ratios (Table 2) when compared with the Comacchio intermediate Group A, revaluation of previous works, newly published research and future works on further Italian context will help assess the validity of such model.

Mixing between natron glass and plant ash glass was also occurring at the Comacchio workshop, even if limited to a very small number of samples. Even the later date of the plant ash group (tenth–eleventh century CE) suggests caution in interpreting the natron–plant ash mixing processes compared with the majority of Comacchio glass, dated before and during the period of workshop activity. The introduction at Comacchio of an earlier dated plant ash glass with a similar composition to plant ash in the late seventh–early eighth century CE at the time of the first workshop activity, is the strongest hypothesis, but currently, no plant ash material has been uncovered for that period in Comacchio.

The heavily recycled nature of the intermediate group also forces us to consider if there was insufficient availability of glass in Northern Italy. While unrecycled Levantine A–Apollonia-type and HIMT glasses stop being in circulation in Comacchio by the early ninth century CE, evidence for circulation of the heavily recycled intermediate glass type until late in the eleventh century in Comacchio suggests that Comacchio glass-workers were relying heavily on recycled glass until that date, and potentially used the same glass for the Bishop’s palace and the Church construction, albeit we cannot be sure the same glass was reworked in Piazza XX Settembre workshop.

These issues also emphasise even more the need for new comparable trace elemental data for glass from European, especially from seventh to ninth century CE Western European contexts. Further analytical work (Bertini et al. in prep.) will clarify the provenance of the raw materials used in Comacchio compositional groups.

References

Andreescu-Treadgold I, Henderson J, with Roe M (2006) Glass from the mosaics on the West Wall of Torcello’s Basilica. Arte Medievale 2:87–142

Barber DJ, Freestone IC, Moulding KM (2009) Ancient copper red glasses: investigation and analysis by microbeam techniques. In: Shortland A, Freestone IC, Rehren TH (eds) From mine to microscope. Advances in the Study of Ancient Technology. Oxbow Books, Oxford, pp 115–127

Boschetti C, Henderson J, Evans J, Leonelli C (2016) Mosaic tesserae from Italy and the production of Mediterranean coloured glass (4rd century BCE--4th century CE) . Part I: Chemical composition and technology Journal of Archaeological Science: Reports 7: 303–311 https://doi.org/10.1016/j.jasrep.2016.05.006

Brill RH (1988) Scientific investigation of the Jalame glass and related finds. In: Weinberg GD (ed) Excavations at Jalame: site of a glass factory in Roman Palestine. University of Missouri Press, Columbia, pp 257–293

Ceglia A, Cosyns P, Nys K, Terryn H, Thienpont H, Meulebroeck W (2015) Late antique glass distribution and consumption in Cyprus: a chemical study. J Archaeol Sci 61:213–222. https://doi.org/10.1016/j.jas.2015.06.009

Ceglia A, Cosyns P, Schibille N, Meulebroeck W (2017) Unravelling provenance and recycling of late antique glass from Cyprus with trace elements. Archaeol Anthropol Sci 11:279–291. https://doi.org/10.1007/s12520-017-0542-1

Cholakova A, Rehren T, Freestone IC (2016) Compositional identification of 6th c. AD glass from the lower danube. J Archaeol Sci Rep 7:625–632. https://doi.org/10.1016/j.jasrep.2015.08.009

Duckworth CN, Mattingly DJ, Chenery S, Smith VC (2016) End of the line? Glass bangles, technology, recycling, and trade in Islamic North Africa. J Glass Stud 58:135–169

Foster HE, Jackson CM (2009) The composition of ‘naturally coloured’ late Roman vessel glass from Britain and the implications for models of glass production and supply. Journal of Archaeological Science 36 (2):189–204 https://doi.org/10.1016/j.jas.2008.08.008

Foy D, Picon M, Vichy M, Thirion-Merle V (2003) Caracterisation des verres de la fin de l’antiquite en mediterranee occidentale: l’emergence de nouveaux courants commerciaux. In: Foy D, Nenna MD (eds) ÉChanges et commerce du verre dans le monde antique, Actes du colloque de l’Association Française pour l’Archéologie du Verre, Maison de l’Orient et de la Méditerranée. Jean Pouilloux, Aix-en-Provence et Marseille, pp 41–85

Freestone IC (1994) Appendix: chemical analysis of ‘raw’ glass fragments. In: Hurst HR (ed) Excavations at Carthage, vol II, 1. The circular harbour, north side. The site and finds other than pottery. British Academy Monographs in Archaeology 4. Oxford University Press, Oxford, p 290

Freestone IC (2015) The recycling and reuse of roman glass: analytical approaches. J Glass Stud 78(3):1–12

Freestone IC (2002) Composition and affinities of glass from the furnaces on the island site, Tyre. Journal of Glass Studies 44: 67–76.

Freestone IC, Gorin-Rosen Y, Hughes MJ (2000) Primary glass from Israel and the production of glass in late antiquity and the early islamic period. In: Marie-Dominique N (ed) La route du verre. Ateliers primaires et secondaires du second millénaire av. J.-C. au Moyen Âge, Maison de l’Orient et de la Méditerranée. Jean Pouilloux, Lyon, 65–83

Freestone IC, Ponting M, Hughes MJ (2002) The origins of Byzantine glass from Maroni Petrera, Cyprus. Archaeometry 44(2):257–272. https://doi.org/10.1111/1475-4754.t01-1-00058

Freestone IC, Leslie K, Thirlwall M, Gorin-Rosen Y (2003) Strontium isotopes in the investigation of early glass production: Byzantine and early Islamic glass from the near east. Archaeometry 45:1932

Freestone IC, Wolf S, Thirlwall M (2005) The production of HIMT glass: elemental and isotopic evidence. Annales du 16ème Congrès de l’Association Internationale pour l’Histoire du Verre, London, pp 153–157

Freestone IC, Hughes MJ, Stapleton CP (2008) The composition and production of Anglo-Saxon glass. In: Evison VI (ed) Catalogue of Anglo-Saxon glass in the British museum. British Museum, London, pp 29–46

Gallo F, Silvestri A, Molin G (2014) Glass from the Archaeological Museum of Adria (North-East Italy): new insights into Early Roman production technologies. J Archaeol Sci 40:2589–2605. https://doi.org/10.1016/j.jas.2013.01.017

Gelichi S (2009) L’isola del vescovo. Gli scavi intorno alla Cattedrale di Comacchio. Edizioni All’Insegna del Giglio, Firenze

Gelichi S (2017) Comacchio: A liminal community in a nodal point during the Early Middle Ages. In: Gelichi S, Gasparri S (eds) Venice and its Neighbours from the 8th to 11th Century. Brill, Leiden, pp 142–167. https://doi.org/10.1163/9789004353619_009

Gelichi S, Calaon D, Grandi E, Lora S, Negrelli C (2008) Uno scavo scomposto. Un accesso alla storia di Comacchio attraverso le indagini presso la Cattedrale. In: Gelichi S (ed) Missioni archeologiche e progetti di ricerca e scavo dell'Università Ca' Foscari-Venezia. VI Giornata di studio. Università Ca' Foscari di Venezia, Venezia, pp 167–178

Gelichi S, Calaon D, Grandi E, Negrelli C (2012) The history of a forgotten town: Comacchio and its archaeology. In: Gelichi S, Hodges R (eds) From one sea to another: trading places in the European and Mediterranean Early Middle Ages, International Conference, Comacchio, 27th–29th March 2009. Brepols, Turnhout, pp 169–206

Gorin-Rosen Y (2000) The ancient glass industry in Israel—summary of the finds and new discoveries. In: Nenna M-D (ed) La route du verre Ateliers primaires et secondaires du second millénaire av. J.C. au Moyen Âge. Maison de l’Orient Méditerranéen. Jean Pouilloux, Lyon, pp 49–63

Henderson J (1988) Electron probe microanalysis of mixed-alkali glasses. Archaeometry 30:77–91. https://doi.org/10.1111/j.1475-4754.1988.tb00436.x

Henderson J (1991) Chemical characterization of Roman glass vessels, enamels and tesserae. In: Vandiver PB, Druzik J, Wheeler GS (eds) Materials issues in art and archaeology II. Materials Research Society Symposium Proceedings, Vol. 185. Materials Research Society, Pittsburgh, pp 601–608

Henderson J (2002) Tradition and experiment in 1st millennium AD glass production – the emergence of early Islamic glass technology in late antiquity. Acc Chem Res 35:594–602. https://doi.org/10.1021/ar0002020

Henderson J, McLoughlin SD, McPhail DS (2004) Radical changes in Islamic glass technology: evidence for conservatism and experimentation with new glass recipes from early and middle Islamic Raqqa, Syria. Archaeometry 46:439–468. https://doi.org/10.1111/j.1475-4754.2004.00167.x

Henderson J, Chenery S, Faber E, Kröger J (2016) The use of electron probe microanalysis and laser ablation-inductively coupled plasma-mass spectrometry for the investigation of 8th-14th century plant ash glasses from the Middle East. Microchem J 128:134–152. https://doi.org/10.1016/j.microc.2016.03.013

Henderson J, Chenery S, Faber EW, Kröger J (in press) Political and technological changes, glass provenance and a new glass production model along the west Asian Silk Road. In Florian Klimscha (ed.), Berlin Studies of the Ancient World volume 67, Berlin: edition Topoi.

Jackson CM (2005) Making colourless glass in the Roman period. Archaeometry 47(4):763–780. https://doi.org/10.1111/j.1475-4754.2005.00231.x

Jackson CM, Paynter S (2016) A great big melting pot: exploring patterns of glass supply, consumption and recycling in Roman Coppergate, York. Archaeometry 58(1):68–95. https://doi.org/10.1111/arcm.12158

Kamber BS, Greig A, Collerson KD (2005) A new estimate for the composition of weathered young upper continental crust from alluvial sediments, Queensland, Australia. Geochim Cosmochim Acta 69:1041–1058. https://doi.org/10.1016/j.gca.2004.08.020

Maltoni S, Chinni T, Vandini M, Cirelli E, Silvestri A, Molin G (2015) Archaeological and archaeometric study of the glass finds from the ancient harbour of Classe (Ravenna-Italy): new evidence. Herit Sci 3:13–19. https://doi.org/10.1186/s40494-015-0034-5

Meisser N, Perseil EA, Brugger J, Chiappero PJ (1999) Strontiomelane, SrMn 4+6Mn3+2O16, a new mineral species of the cryptomelane group from St. Marcel-Praborna, Aosta Valley, Italy. Can Mineral 37(3):673–678

Mirti P, Lepora A, Sagui L (2000) Scientific analysis of seventh-century glass fragments from the Crypta Balbi in Rome. Archaeometry 42:359–374. https://doi.org/10.1111/j.1475-4754.2000.tb00887.x

Mirti P, Davit P, Gulmini M, Saguì L (2001) Glass fragments from the Crypta Balbi in Rome: the composition of eighth-century fragments. Archaeometry 43(4):491–502. https://doi.org/10.1111/1475-4754.00032

Montanari M (1986) Il Capitolare di Liutprando: note di storia dell’economia e dell’alimentazione. In: La civiltà comacchiese e pomposiana dalle origini preistoriche al tardo medioevo: atti del Convegno Nazionale di Studi Storici, Comacchio 17-19 Maggio 1984. La Nuova Alfa edizioni, Bologna, pp 461–475

Negrelli C (2012) Towards a definition of early medieval pottery: amphorae and other vessels in the northern Adriatic between the 7th and the 8th centuries. In: Gelichi S, Hodges R (eds) From one sea to another: trading places in the European and Mediterranean Early Middle Ages, International conference, Comacchio, 27th–29th March 2009. Turnhout, Brepols, pp 394–415. https://doi.org/10.1484/M.SCISAM-EB.1.101100

Nenna MD (2014) Egyptian glass abroad: HIMT glass and its markets. In: Keller D, Price J, Jackson CM (eds) Neighbours and successors of Rome: traditions of glass production and use in Europe and the Middle East in the later 1st millennium AD. Oxbow Books, York, pp 177–193 https://doi.org/10.2307/j.ctvh1dq24.22

Neri E, Schibille N, Pellegrino M, Nuzzo D (2019) A Byzantine connection: Eastern Mediterranean glasses in medieval Bari. J Cult Herit 38:253–260. https://doi.org/10.1016/j.culher.2018.11.009

Paynter S (2008) Experiments in the reconstruction of roman wood-fired glassworking furnaces: waste products and their formation processes. J Glass Stud 50:271–290 https://www.jstor.org/stable/24191332

Phelps M, Freestone IC, Gorin-Rosen Y, Gratuze B (2016) Natron glass production and supply in the late antique and early medieval Near East: the effect of the Byzantine-Islamic transition. J Archaeol Sci 75:57–71. https://doi.org/10.1016/j.jas.2016.08.006

Rosenow D, Rehren T (2014) Herding cats: Roman to late antique glass groups from Bubastis, northern Egypt. J Archaeol Sci 49:170–184. https://doi.org/10.1016/j.jas.2014.04.025

Schibille N, Freestone IC (2013) Composition, Production and Procurement of Glass at San Vincenzo al Volturno: An Early Medieval Monastic Complex in Southern Italy. PLoS ONE 8 (10):e76479 https://doi.org/10.1371/journal.pone.0076479

Schibille N, Meek A, Tobias B, Entwistle C, Avisseau-Broustet M, Da Mota H, Gratuze B (2016a) Comprehensive chemical characterisation of byzantine glass weights. PLoS One 11(12):e0168,289. https://doi.org/10.1371/journal.pone.0168289

Schibille N, Sterrett-Krause A, Freestone IC (2016b) Glass groups, glass supply and recycling in Late Roman Carthage. Archaeol Anthropol Sci 9:1223–1241. https://doi.org/10.1007/s12520-016-0316-1

Shortland A, Schachner L, Freestone IC, Tite M (2006) Natron as a flux in the early vitreous materials industry: sources, beginnings and reasons for decline. J Archaeol Sci 33(4):521–530

Silvestri A (2008) The coloured glass of Iulia Felix. J Archaeol Sci 35:1489–1501

Silvestri A, Marcante A (2011) The glass of Nogara (Verona): a “window” on production technology of mid-Medieval times in Northern Italy. J Archaeol Sci 38(10):2509–2522. https://doi.org/10.1016/j.jas.2011.03.014

Silvestri A, Molin G, Salviulo G (2008) The colourless glass of Iulia Felix. J Archaeol Sci 35:331–341

Tal O, Jackson-Tal RE, Freestone IC (2004) New evidence of the production of raw glass at late Byzantine Apollonia-Arsuf, Israel. J Glass Stud 46:51–66

Uboldi M, Verità M (2003) Scientific analyses of glasses from Late Antique and Early Medieval archaeological sites in northern Italy. Journal of Glass Studies 45:115–137

Verità M, Renier A, Zecchin S (2002) Chemical analyses of ancient glass findings excavated in the Venetian lagoon. Journal of Cultural Heritage 3:261–271 https://doi.org/10.1016/S1296-2074(02)01235-9

Verità M, Toninato T (1990) A comparative analytical investigation on the origins of the Venetian glassmaking. Rivista della Stazione sperimentale del vetro 20:169–176

Wedepohl KH, Baumann A (2000) The use of marine molluskan shells for roman glass and local raw glass production in the Eifel area (western Germany). Naturwissenschaften 87:129–132 https://doi.org/10.1007/s001140050690

Whitehouse D (2002) The transition from natron to plant ash in the Levant. J Glass Stud 44:193–196

Acknowledgements

The research presented was undertaken as part of a PhD project funded by a grant from the AHRC - Arts and Humanities Research Council of Great Britain (1524974) awarded to Camilla Bertini. LA-ICP-MS analyses were funded by the joint BGS-Nottingham Univ., Centre for Environmental Geochemistry. Samples from Comacchio were obtained with the kind permission the Soprintendenza dei Beni Culturali dell’Emilia Romagna, Italy. We would like to thank Professor Gelichi for his extremely valuable comments on this manuscript; Dr. Edward Faber of the Microanalysis Research Facility, the University of Nottingham, for assistance in preparing the samples; and Dr. Ferri and Dr. Grandi for the assistance with the identification and dating of the samples. Simon Chenery published with permission from the Director of the British Geological Survey.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM1

(XLSX 130 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bertini, C., Henderson, J. & Chenery, S. Seventh to eleventh century CE glass from Northern Italy: between continuity and innovation. Archaeol Anthropol Sci 12, 120 (2020). https://doi.org/10.1007/s12520-020-01048-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-020-01048-8