Abstract

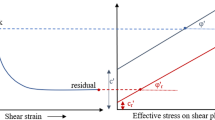

Data analytics are becoming important to better characterize the material behavior. In this study, over 3000 data from the laboratory studies and literature for the field soils were analyzed to quantify the relationship between the density, natural moisture content, shear strength, deviatoric shear stress at failure (3-dimension stress) with the liquid limit (LL). With the increase in the construction of wells, tunnels, piles, and storage facilities, there is interest in determining the safety of soils under multiaxial loading. The range of liquid limit (LL) for the soil investigated varied from 20 to 60%. The ranges of the dry density (γd) and the natural moisture content (MC) for the soils varied from 1.2 to 2.6 g/cm3 and 13 to 56% respectively. The statistical distribution of the data collected varied from normal distribution to Weibull distribution. Vipulanandan correlation model correlated some of the physical properties of the soils. Vipulanandan failure model was used to the failure stresses for the soil and compared to the Mohr-Coulomb failure model and other failure models. Based on the coefficient of determination and root mean square error, the Vipulanandan failure model predicted the results more reliable than the other models. Vipulanandan failure model also predicted the maximum shear strength limit and maximum second deviatoric stress invariant for the soil, whereas none of the other models predicted the maximum shear tolerance for the soil investigated. With the Vipulanandan failure model, the maximum shear strength predicted for the soil was 57 kPa. The maximum second deviatoric stress invariant for the soil in the LL range of 20 and 60% varied from 44 to 30 kPa.

Similar content being viewed by others

References

Ahmed C, Mohammed A, Tahir A (2020a) Geostatistics of strength, modeling and GIS mapping of soil properties for residential purpose for Sulaimani City soils, Kurdistan Region, Iraq. Mod Earth Syst Environ 6:1–15. https://doi.org/10.1007/s40808-020-00715-y

Ahmed C, Mohammed A, Saboonchi A (2020b) ArcGIS mapping, characterisations and modelling the physical and mechanical properties of the Sulaimani City soils, Kurdistan Region, Iraq. Geomech Geoeng:1–14. https://doi.org/10.1080/17486025.2020.1755464

Anantanasakul P, Yamamuro JA, Lade PV (2012) Three-dimensional drained behavior of normally consolidated anisotropic kaolin clay. Soils Found 52(1):146–159. https://doi.org/10.1016/j.sandf.2012.01.014

Arulrajah A, Bo MW (2008) Characteristics of Singapore marine clay at Changi. Geotech Geol Eng 26(4):431–441. https://doi.org/10.1007/s10706-008-9179-2

Bilgin Ö, Mansour E (2013) Variability of soil properties and reliability of empirical equations on soil settlement predictions. In Foundation Engineering in the Face of Uncertainty: Honoring Fred H. Kulhawy, Proceeding, pp 298–307, https://doi.org/10.1061/9780784412763.024

Bowles JE (1998) Foundation analysis and design. McGraw-Hill Book Company, New York 800 pp

Cerato AB (2001) Influence of specific surface area on geotechnical characteristics of fine-grained soils. Unpublished MSc Thesis, Department of Civil and Environmental Engineering, University of Massachusetts, Amherst, Massachusetts

Chang C, Haimson B (2012) A failure criterion for rocks based on true triaxial testing. In The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007-2014, pp 259–262. Springer, Cham, https://doi.org/10.1007/978-3-319-07713-0_24.

Das B (2011) Principles of Foundation Engineering, Cengage Learning, Stamford, Connecticut, 794 pp.

Degirmenci N, Okucu A, Turabi A (2017) Application of phosphogypsum in soil stabilization. Build Environ 42(9):3393–3398. https://doi.org/10.1016/j.buildenv.2006.08.010

Fredlund DG, Rahardjo H, Gan JKM (1987) Non-linearity of strength envelope for unsaturated soils. In Proc. 6th Int. Conf. Expansive Soils, New Delhi, Vol. 1, pp 49–54

Ganji PK (2006) Statistical correlations of geotechnical properties, undrained shear strength, Texas Cone Penetrometer (TCP) blow count values with depth of Houston clayey soil, Masters Thesis, Department of Civil and Environmental Engineering, University of Houston, Houston, Texas.

Gregory GH, Baryun A (2010) Correlation of fully-softened shear strength of clay soil with index properties phase I (No. FHWA-OK-10-04). Oklahoma. Dept. of Transportation. Planning and Research Division

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186. https://doi.org/10.1016/S1365-1609(97)80069-X

Joseph D (2010) Testing and modeling of proppant particles, pavements and retaining walls, Master’s Thesis, Department of Civil and Environmental Engineering, University of Houston, Houston, Texas

Kim M (2007) Testing and modeling of large cone penetrometer in clay soils, Doctoral dissertation, Department of Civil and Environmental Engineering, University of Houston, Houston, Texas

Liu MD, Carter JP (2003) General strength criterion for geomaterials. Int J Geomech 3(2):253–259. https://doi.org/10.1061/(ASCE)1532-3641(2003)3:2(253)

Liu J, Shi B, Jiang H, Huang H, Wang G, Kamai T (2011) Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng Geol 117(1-2):114–120. https://doi.org/10.1016/j.enggeo.2010.10.011

Lytton R, Aubeny C, Bulut R (2005) Design procedure for pavements on expansive soils. Texas Transportation Institute, Texas A and M University System

Mahmood W, Mohammed A (2019) New Vipulanandan pq model for particle size distribution and groutability limits for sandy soils. J Test Eval 48(5). https://doi.org/10.1520/JTE20180606.

Mohammed AS (2014) Characterization and modeling of polymer-treated and nano particle modified sulfate contaminated soils, drilling muds, and hydraulic fracturing fluids under groundwater, doctoral dissertation, Department of Civil and Environmental Engineering, University of Houston, Houston, Texas

Mohammed AS (2017) Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt J Pet 26(3):791–802. https://doi.org/10.1016/j.ejpe.2016.10.018

Mohammed AS (2018a, pp. 267-281) Property correlations and statistical variations in the geotechnical properties of (CH) clay soils. Geotech Geol Eng 36(1):1–15. https://doi.org/10.1007/s10706-017-0325-6

Mohammed AS (2018b) Electrical resistivity and rheological properties of sensing bentonite drilling muds modified with lightweight polymer. Egypt J Pet 27(1):55–63. https://doi.org/10.1016/j.ejpe.2017.01.002

Mohammed AS (2018c) Vipulanandan models to predict the electrical resistivity, rheological properties and compressive stress-strain behavior of oil well cement modified with silica nanoparticles. Egypt J Pet 27(4):1265–1273. https://doi.org/10.1016/j.ejpe.2018.07.001

Mohammed AS (2019) Vipulanandan models to predict the mechanical properties, fracture toughness, pulse velocity and ultimate shear strength of shale rocks. Geotech Geol Eng 37(2):625–638. https://doi.org/10.1007/s10706-018-0633-5

Mohammed CVA Characterizing the index properties, free swelling, stress–strain relationship, strength and compacted properties of polymer treated expansive CH clay soil using Vipulanandan models. https://doi.org/10.1007/s10706-020-01387-2.

Mohammed A Vipulanandan model for the rheological properties with ultimate shear stress of oil well cement modified with nanoclay. https://doi.org/10.1016/j.ejpe.2017.05.007

Mohammed A, Mahmood W (2018a) Vipulanandan failure models to predict the tensile strength, compressive modulus, fracture toughness and ultimate shear strength of calcium rocks. Int J Geotech Eng:1–11. https://doi.org/10.1080/19386362.2018.1468663

Mohammed A, Mahmood W (2018b) Statistical variations and new correlation models to predict the mechanical behavior and ultimate shear strength of gypsum rock. Open Eng 8(1):213–226. https://doi.org/10.1515/eng-2018-0026

Mohammed AS, Vipulanandan C (2014) Compressive and tensile behavior of polymer treated sulfate contaminated CL soil. Geotech Geol Eng 32(1):71–83. https://doi.org/10.1007/s10706-013-9692-9

Mohammed A, Vipulanandan C (2015) Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. Geotech Geol Eng 33(4):1099–1114. https://doi.org/10.1007/s10706-015-9890-8

Mohammed A, Salih A, Raof H (2020) Vipulanandan constitutive models to predict the rheological properties and stress–strain behavior of cement grouts modified with metakaolin. J Test Eval 48(5):20180271. https://doi.org/10.1520/JTE20180271

Puppala A, Mohammad L, Allen A (1996) Engineering behavior of lime-treated Louisiana subgrade soil. Transportation Research Record: Journal of the Transportation Research Board, (1546):24–31, https://doi.org/10.1177/0361198196154600103

Qadir W, Ghafor K, Mohammed A (2019) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Advances in Civil Engineering, Article ID 7013908, https://doi.org/10.1155/2019/7013908

Randolph M, Gourvenec S (2011) Offshore geotechnical engineering. Spon Press, New York, 528 pp

Sharma RP, Verma NC (1997) Tensile strength of compacted clay by disc bending test. In Proceedings of The International Conference on Soil Mechanics and Foundation Engineering-International Society For Soil Mechanics and Foundation Engineering Vol 1, pp 197–200

Shen ZJ (1995) Summary on the failure criteria and yield functions in Chinese. Chin J Geotech Eng 17(2):1–9. https://doi.org/10.1016/S1674-5264(09)60076-4

Sivaruban N (2008) Construction and maintenance issues related to transportation infrastructure. Master’s Thesis, Department of Civil and Environmental Engineering, University of Houston, Houston, Texas

Tang CS, Pei XJ, Wang DY, Shi B, Li J (2014) Tensile strength of compacted clayey soil. J Geotech Geoenviron 141(4):04014122. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001267

Tiwari B, Ajmera B (2011) A new correlation relating the shear strength of reconstituted soil to the proportions of clay minerals and plasticity characteristics. Appl Clay Sci 53(1):48–57. https://doi.org/10.1016/j.clay.2011.04.021

Tollenaar RN, van Paassen LA, Jommi C (2017) Experimental evaluation of the effects of pull rate on the tensile behavior of a clay. Appl Clay Sci 144:131–140. https://doi.org/10.1016/j.clay.2017.04.026

Turkoz M, Vural P (2013) The effects of cement and natural zeolite additives on problematic clay soils. Sci Eng Compos Mater 20(4):395–405. https://doi.org/10.1515/secm-2012-0104

Usluogullari OF, Vipulanandan C (2011) Stress-strain behavior and California bearing ratio of artificially cemented sand. J Test Eval 39(4):1–9. https://doi.org/10.1520/JTE103165

Vipulanandan C, Krishnan S (1990) Solidification/stabilization of phenolic waste with cementitious and polymeric materials. J Hazard Mater 24(2-3):123–136. https://doi.org/10.1016/0304-3894(90)87004-2

Vipulanandan C, Mohammed AS (2014) Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J Pet Sci Eng 122:38–47. https://doi.org/10.1016/j.petrol.2014.08.004

Vipulanandan C, Mohammed A (2015) XRD and TGA, swelling and compacted properties of polymer treated sulfate contaminated CL soil. J Test Eval 44(6):2270–2284. https://doi.org/10.1520/JTE20140280

Vipulanandan C, Mohammed A (2018) New Vipulanandan failure model and property correlations for sandstone, shale and limestone rocks. ASCE, GSP 295:365–376. https://doi.org/10.1061/9780784481585.036

Vipulanandan C, Ahossin Guezo YJ, Bilgin O (2007) Geotechnical properties of marine and deltaic soft clays, Proceedings (CD). Advances in Measurements and Modeling of Soil Behavior, GSP 173, ASCE, https://doi.org/10.1061/40917(236)5

Vipulanandan C, Vembu K, Gattu V (2018a) Highway bridge supported on ACIP piles in clay soils: instrumentation, monitoring and performance of service piles. ASCE, GSP 299:50–67. https://doi.org/10.1061/9780784481639.002

Vipulanandan C, Mohammed A, Samuel RG (2018b) Fluid loss control in smart bentonite drilling mud modified with nanoclay and quantified with Vipulanandan fluid loss Model, Offshore Technology Conference (OTC) 2018, OTC-28974-MS, https://doi.org/10.4043/28947-MS

Wang JJ, Zhu JG, Chiu CF, Zhang H (2007) Experimental study on fracture toughness and tensile strength of a clay. Eng Geol 94(1-2):65–75. https://doi.org/10.1016/j.enggeo.2007.06.005

Westerberg B, Müller R, Larsson S (2015) Evaluation of undrained shear strength of Swedish fine-grained sulphide soils. Eng Geol 188:77–87. https://doi.org/10.1016/j.enggeo.2015.01.007

Ye W, Zhang Y, Chen B, Zhou X, Xie Q (2010) Shear strength of an unsaturated weakly expansive soil. J Rock Mech Geotech Eng 2(2):155–161. https://doi.org/10.3724/SP.J.1235.2010.00155

Yılmaz I (2000) Evaluation of shear strength of clayey soils by using their liquidity index. Bull Eng Geol Environ 59(3):227–229. https://doi.org/10.1007/s100640000056

Yu MH, Zan YW, Zhao J, Yoshimine M (2002) A unified strength criterion for rock material. Int J Rock Mech Min Sci 39(8):975–989. https://doi.org/10.1016/S1365-1609(02)00097-7

Zhao XD, Zhou GQ, Tian QH (2009) Study on the shear strength of deep reconstituted soils. Min Sci Technol (China) 19(3):405–408

Funding

The study was supported by the Center for Innovative Grouting Materials (CIGMAT) and the Texas Hurricane Center for Innovative Technology (THC-IT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Vipulanandan, C., Mohammed, A. 3-dimension stresses and new failure model to predict behavior of clay soils in various liquid limit ranges. Arab J Geosci 14, 160 (2021). https://doi.org/10.1007/s12517-021-06553-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-06553-1