Abstract

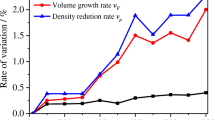

Variations in the mechanical properties (compressive strength, elastic modulus, tensile strength, and fracture toughness) of granite were analyzed as functions of temperature. It was found that above 200 °C, tensile strength and fracture toughness tended to decrease with temperature, while variations in the compressive strength and elastic modulus demonstrated decreasing trends when the heating temperature exceeded 400 °C. The temperature ranges of room temperature—200 and above 600 °C—corresponded to an undamaged state and strongly/completely damaged state, respectively. It is suggested that 400 °C might be a critical threshold of thermal damage to granite. Based on results of statistical tests, a sharp decrease in mechanical properties can be recognized, accompanied by a drastic growth in peaking strain and acoustic emission rate. This phenomenon may be associated with the α/β phase transition of quartz.

Similar content being viewed by others

References

Aditya S, Nandi TK, Pal SK, Majumder AK (2017) Pre-treatment of rocks prior to comminution – A critical review of present practices[J]. Int J Min Sci Technol 27(2):339–348

Alm O, Jaktlund LL, Kou SQ (1985) The influence of microcrack density on the elastic and fracture mechanical properties of Stripa granite. Phys Earth Planet Inter 40:161–171

BauerS J, JohnsonB (1979). Effects of slow uniform heating on the physical properties of the Westerly and Charcoal granites. In proceedings of the 20th U.S. Symposium on rock mechanics, 4–6, June, Austin, Texas, pp7–18

Chen Y, Wang CY (1980) Thermally induced acoustic emission in Westerly granite. Geophys Res Lett 7(12):1089–1092

Chen YL, Ni J, Shao W, Azzam R (2012) Experimental study on the influence of temperature on the mechanical properties of granite under uni-axial compression and fatigue loading. Int J Rock Mech Min 56:62–66

Du SJ, Liu H, Zhi HT, Chen HH (2004) Testing study on mechanical properties of post-high-temperature granite (in Chinese). Chin J Rock Mech Eng 23(14):2359–2364

Dutton SP, Loucks RG (2010) Diagenetic controls on evolution of porosity and permeability in lower Tertiary Wilcox sandstones from shallow to ultradeep (200–6700 m) burial, Gulf of Mexico Basin, USA. Mar Petrol Geol 27(8):1775–1787. https://doi.org/10.1016/j.marpetgeo.2009.12.010

Etienne FH, Poupert R (1989) Thermally induced microcracking in granites: characterization and analysis. Int J Rock Mech Min Sci 26(2):125–134. https://doi.org/10.1016/0148-9062(89)90001-6

Fredrich JT, Wong T (1986) Micromechanics of thermally induced cracking in three crustal rocks. J Geophys Res 91(B12):12743–12754 764

Glover PWJ, Baud P, Darot M et al (1995) α/β phase transition in quartz monitored using acoustic emissions. Geophys J Int 120:775–782

Hajpál M, Török Á (2004) Mineralogical and colour changes of quartz sandstones by heat. Environ Geol 46:311–322

Heuze FE (1983) High-temperature mechanical, physical and thermal properties of granitic rocks—a review. Int J Rock Mech Min Sci Geomech Abstr 20(1):3–10. https://doi.org/10.1016/0148-9062(83)91609-1

Jason DP, Carlson SR, Young RP, Hutchins DA (1993) Ultrasonic imaging and acoustic emission monitoring of thermally induced microcracks in Lac du Bonnet granite. J Geophys Res Solid Earth 98(B12):22231–22243

Kou SQ (1987) Effect of thermal cracking damage on the deformation and failure of granite (in Chinese). Acta Mech Sin 19(6):550–557

Liang B, Gao HM, Lan YW (2005) Theoretical analysis and experimental study on relation between rock permeability and temperature (in Chinese). Chinese J Rock Mech Eng 24(12):53–58

Nasseri MHB, Schubnel A, Young RP (2007) Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly granite. Int J Rock Mech Min Sci 44:601–616

Nasseri MHB, Tatone BSA, Grasselli G, Young RP (2009) Fracture toughness and fracture roughness interrelationship in thermally treated Westerly granite. Pure Appl Geophys 166(5-7):801–822. https://doi.org/10.1007/s00024-009-0476-3

Rao GMN, Murthy CR (2001) Dual role of microcracks: toughening and degradation. Can J Earth Sci 38(2):427–440

Roddy DJ, Younger PL (2010) Underground coal gasification with CCS: a pathway to decarbonising industry. Energy Environ Sci 3(4):400–407. https://doi.org/10.1039/b921197g

Rutqvist J, Wu YS, Tsang CF, Bodvarsson G (2002) A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Int J Rock Mech Min Sci 39(4):429–442. https://doi.org/10.1016/S1365-1609(02)00022-9

Shafiei A, Dusseault MB (2013) Geomechanics of thermal viscous oil production in sandstones. J Pet Sci Eng 103:121–139. https://doi.org/10.1016/j.petrol.2013.02.001

Somerton WH, Boozer GD (1961) A method of measuring thermal diffusivities of rocks at elevated temperatures. AICHE J 7(1):87–90. https://doi.org/10.1002/aic.690070121

Sun Q, Zhang ZZ, Xue L, Zhu SY (2013) Physical-mechanical properties variation of rock with phase transformation under high temperature. (in Chinese). Chin J Rock Mech Eng 32(5):935–942

Sun Q, Zhang WQ, Xue L et al (2015) Thermal damage pattern and thresholds of granite. Environ Earth Sci 74(3):2341–2349. https://doi.org/10.1007/s12665-015-4234-9

Sundberg J, Back PE, Christiansson R, Hökmark M, Ländell M, Wrafter J (2009) Modelling of thermal rock mass properties at the potential sites of a Swedish nuclear waste repository. Int J Rock Mech Min Sci 46(6):1042–1054. https://doi.org/10.1016/j.ijrmms.2009.02.004

WangGD (2003). Experiment research on the effects of temperature and viscoelastoplastic analysis of Beishan granite (in Chinese). Xi’an: master. Thesis, Xi’an institue of science and technology

Xi DY (1994) Physical characteristics of mineral phase transition in the granite (in Chinese). Acta Mineral Sin 14(3):223–227

Xi DY (1995) Physico-mechanical property changes associated with mineral phase transition in granite. Chin J Geochem 14(3):250–255

Xu XC, Liu QS (2000) A preliminary study on basic mechanical properties for granite at high temperature (in Chinese). Chin J Geotech Eng 22(3):332–335

Yin TB (2012) Study on dynamic behavior of rocks considering thermal effect (in Chinese). Changsha: Ph.D. Thesis, Central south university

Zhao F, Cai M (2007) Influence of high temperature on anchoring system of cable bolts at stope hanging wall (in Chinese). J Liaoning Tech Univ 26:524–526

Zhi LP, Xu JY, Liu ZQ, Liu S, Chen TF (2012) Research on ultrasonic characteristics and Brazilian splitting-tensile test of granite under post-high temperature (in Chinese). Rock Soil Mech 33(s1):61–66

Zhu HH, Yan ZG, Deng T et al (2006) Testing study on mechanical properties of tuff, granite and breccia after high temperatures (in Chinese). Chin J Rock Mech Eng 25(10):1945–1950

Funding

This research was supported by “the Fundamental Research Funds for the Central Universities” (no. 2017XKZD07) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Sun, Q. & Pan, X. Variation of mechanical properties of granite after high-temperature treatment. Arab J Geosci 11, 43 (2018). https://doi.org/10.1007/s12517-018-3395-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3395-8