Abstract

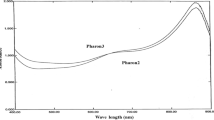

Humic acid can be produced by a Bacillus megaterium strain, AS019, using vinasse (sugarcane mill wastewater) at an optimal concentration of 12 °Bx. Using single factor and orthogonal experiments, the optimal culture conditions were determined: optimum inoculum size, 15%; initial pH, 6.0; culture time, 8 days; rotation speed, 180 rpm; and temperature, 28 °C. Under the optimal conditions, the humic acid production rate for the strain was 49.50 g/L. The results of characterization and infrared spectral analysis revealed that the produced humic acid contained a variety of reactive functional groups.

Similar content being viewed by others

References

Fein, J.B., J.F. Boily, K. Guclu, and E. Kaulbach. 1999. Experimental study of humic acid adsorption onto bacteria and Al-oxide mineral surfaces. Chemical Geology 162: 33–451.

Feng, Y.Q. 2005. Developmental direction of humic acid fertilizer in China and its applicable example. Chemical Fertilizer Design 43: 56–61.

Guan, P.F. 2005. The application of humic acid and humic fertilizer. Jilin Vegetables 5: 29–30.

Guo, B., and C.X. Zhu. 2005. Bio-active humic acid in environment remediation. Humic Acid 5: 3–8.

He, L.Q. 1999. Humic acid of research and application with biological technology, 115–164. Beijing: Chemical Industry Press.

Huang, J.F., Y.L. Zhao, J.X. Zhao, J.F. Jiao, and T.Y. Li. 2007. The extraction of humic acid and its component content determination. Sichuan Animal and Veterinary Sciences 5: 27–28.

Jesenak, K. 1982. The isolation of humic acid by means of extraction with 1 M sodium hydroxide solution. Acta Fac Rerum Nat Univ Comenianae Chim 30: 113–118.

Jiang, P.W., Z.J. Ma, and Z.P. Li. 2009. The technology of extraction of humic acid from lignite and its status in application research. China Mining Magazine 18: 356–359.

Khan, S.U. 1971. Distributio and characteristics of organic matter extracted from the black solonetzic and black chernozemic soils of Alberta: the humic acid fraction. Soil Science 112: 401–408.

Li, X.W., J.Y. Jin, and X.K. Ren. 2009. Application of humic fertilizer. Modernizing Agriculture 3: 30–31.

Liu, K.D. 1999. Status and prospect of application field of humic acid. Fine and Specialty Chemicals 20: 13–14.

Luan, J. 1995. The design and optimization method in modern experiment, 191–2011. Shanghai: Shanghai Jiaotong University Press.

Ranjbar, H., R. Shahryari, and V. Mollasadeghi. 2012. Production of wheat seeds with presence of humic fertilizer after anthesis drought condition. African Journal of Agricultural Research 7: 307–310.

Shahryari, R., A. Gadimov, E. Gurbanov, M. Valizadeh, and V. Mollasadeghi. 2011. Wheat genotypes response to terminal drought at presence of a humic fertilizer using stress tolerance. Advances in Environmental Biology 5: 166–168.

Shan, J.J., C.S. Zhang, and J.C. Zhang. 2005. Exploiting new resource of BFA by bio-technique. Humic Acid 2: 1–3.

Sposito, G., K.M. Holtzclaw, and J. Baham. 1976. Analytical properties of the soluble, metal-complexing fractions in sludge-soil mixtures: II. Comparative structural chemistry of fulvic acid. Soil Science Society of America Journal 40: 461–467.

Stevenson, F.J. 1994. Humus chemistry: genesis, composition, reactions. New York: Wiley.

Wang, R.X. 2000. Mathematical statistics, 120–158. Xi’an: Xi’an Jiaotong University Press.

Xu, E.G., and X.C. Zeng. 2004. Humic pesticide and its prospect of development. Humic Acid 2: 1–6.

Xu, Q.X., X.T. Chen, Z.J. He, and Z. Liu. 2005. Study of processing paper mill disuse materiel-wheal straw with zymogen dosage. Tianjin Agricultural Sciences 11 (4): 18–19.

Yang, M., H.B. Wang, and Y. Dai. 2002. Research on extractant of humic acid from humic soil and its infrared spectroscopy. Journal of Yunnan University for Nationalities (Natural Sciences Edition) 11: 573–574.

Zeng, X.C. 2005. Humic acid and source security of production food. Humic Acid 4: 1–10.

Funding

This work was supported in part by Guangxi Special Funds for Bagui Scholars (2013-03), Project of Guangxi Sugarcane Innovation team of National Modern Agriculture Industry Technology System (gjnytxgxcxtd-03).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, N., Deng, ZN., Wei, YW. et al. Production of Humic Acid by a Bacillus megaterium Strain Using Vinasse. Sugar Tech 20, 163–167 (2018). https://doi.org/10.1007/s12355-017-0554-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-017-0554-2