Abstract

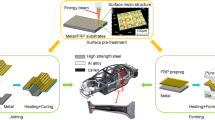

In this article, a newly developed method for forming metal sheets together with long fiber-reinforced thermoplastics (LFT) to hybrid parts is presented. The idea of combining two different materials in one part is nothing new, but most of the existing processes use at least separate production techniques for each material and an additional joining operation. The special characteristic of this new process is realized by a combined forming tool for both sheet metal and LFT to create a hybrid part with only one necessary and simultaneously executed process step. Besides contact to the punch, the metal sheet is also formed by the molten LFT material, which behaves like a hydraulic fluid in hydroforming processes. With this method, it is possible to reduce the thickness of sheet metal components by adding a LFT reinforcement structure. The interface connection between the metal sheet and LFT is realized by using a bonding agent, which is previously applied to the metal sheet via coil or powder coating. To achieve this hybrid forming process, new tool and sealing concepts have been developed and the corresponding process parameters were identified and optimized. As a result, the innovative process offers a cost- and time-efficient solution for multi-material lightweight design.

Similar content being viewed by others

References

Zhang S, Danckert J (1998) Development of hydro-mechanical deep drawing. J Mater Process Technol 83(1-3):14–25. https://doi.org/10.1016/S0924-0136(98)00039-9

Siegert K, Haeussermann M, Loesch B, Rieger R (2000) Recent developments in hydroforming technology. J Mater Process Technol 98(2):251–258. https://doi.org/10.1016/S0924-0136(99)00206-X

Schemme M (2008) LFT – development status and perspectives. Plastics, Additives & Compounding 10(2):38–43. https://doi.org/10.1016/S1464-391X(08)70060-6

Tatara R (2017) 14 – compression molding. In: Applied plastics engineering handbook, Second edn. Elsevier, Amsterdam, pp 291–320

Buerkle E, Sieverding M, Mitzler J (2003) Spritzgiessverarbeitung von langfaser-verstärktem PP. Kunststoffe 3/2003. Carl Hanser Verlag, München, pp 47–50

Starke J (2016) Carbon Composites in Automotive Structural Applications. EuCIA. Composites and Sustainability, Brussels

Ehrenstein G (2004) Handbuch Kunststoff-Verbindungstechnik. Carl Hanser Verlag, München

Hussain M, Rauscher B, Tekkaya A (2008) Wirkmedienbasierte Herstellung hybrider Metall-Kunststoff-Verbundbauteile mit Kunststoffschmelzen als Druckmedium. Mater Werkst 39(9):585–672. https://doi.org/10.1002/mawe.200800333

Zorn W, Albert A, Drossel W, Raithel D, Nendel W (2014) Fertigung von Metall / Kunststoff-Verbundbauteilen. Wt Werkstatttechnik online, vol 104. Springer-VDI-Verlag, Düsseldorf, pp 614–619

Landgrebe D, Kraeusel V, Rautenstrauch A, Albert A, Wertheim R (2016) Energy-efficiency in a hybrid process of sheet metal forming and polymer injection moulding. Procedia CIRP 40:109–114. https://doi.org/10.1016/j.procir.2016.01.068

Schild J, Ch H (2016) Integriertes Tiefziehen im Spritzgiessprozess. In: 28. Internationales Kolloquium Kunststofftechnik, Shaker, Aachen, pp 709–720

Landgrebe D, Kraeusel V, Rautenstrauch A, Awiszus (2017) Energy-Efficiency and Robustness in a Hybrid Process of Hydroforming and Polymer Injection Molding, vol 8. Procedia Manufacturing, pp 746–753. https://doi.org/10.1016/j.promfg.2017.02.096

N.N. (2017) Lightweight plastic components for car body. https://www.elringklinger.de/de/node/3246. Accessed 12 December 2017

Wehmeyer R (2012) Herstellung von Kunststoff / Metall-Bauteilen mit integrierter Umformung im Spritzgiessprozess. PHD thesis. RWTH Aachen University

Kellner P, Froeschle M, Steinbach K (2014) Die 3D-Hybridtechnologie: Eine neu-artige Stahl-GFK-Hybridbauweise für hoechstbelastete Karosseriestrukturen, vol 18. Internationales Dresdener Leichtbausymposium, Dresden

Modler N, Adam F, Maass J (2015) Intrinsic lightweight steel-composite hybrids for structural components. Materials Science Forum 825–826:401–408. https://doi.org/10.4028/www.scientific.net/MSF.825-826.401

Fang X (2014): patent DE102014004359A1, Deutsches Patent- und Markenamt

NN (2016) Hoechste Waermeeinwirkung per Infrarot. Sonderdruck K Zeitung Ausgabe, vol 7. Giesel Verlag, Hannover

Risthaus M (2017) VESTAMELT® Hylink adhesion promoter (technical information). http://adhesives-sealants.evonik.com/sites/lists/RE/DocumentsAC/FlyerVESTAMELTHylink.pdf. Accessed 30 June 2017

Acknowledgments

This research is supported by the Federal Ministry of Education and Research (BMBF) in the context of a project named “MultiForm” and supervised by the Project Management Agency Karlsruhe (PTKA) at the Karlsruhe Institute of Technology (KIT). We want to express our gratitude to BMBF and PTKA for the support. Additionally, we thank our industrial project partners Weber Fibertech, voestalpine Automotive Components Schwäbisch Gmünd, Sprick Technologies and SimpaTec as well as Altair Engineering, Bond-Laminates, Evonik and Volkswagen for providing technology consulting and supports.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, X., Kloska, T. Hybrid forming of sheet metals with long Fiber-reinforced thermoplastics (LFT) by a combined deep drawing and compression molding process. Int J Mater Form 13, 561–575 (2020). https://doi.org/10.1007/s12289-019-01493-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-019-01493-4