Abstract

Purpose

Wet granulation is widely used in the pharmaceutical industry. This advantageous technology is capable of enhancing compression and powder handling, decreasing ingredient segregation, and promoting blend and content uniformity. Currently, a high level of interest exists in the continuous version of this technology, both by the US Food and Drug Administration (FDA), and by pharmaceutical manufacturers.

Methods

In this paper, a continuous high shear wet granulation process was examined based on a placebo formulation comprising 70% ∂-lactose monohydrate and 30% microcrystalline cellulose (Avicel® PH101). Granulation was then carried out in a continuous high shear mixer granulator, Glatt GCG 70. The impact of two process variables (rotation speed and liquid/solid (L/S) ratio) and two design parameters (blade configuration and nozzle position) were evaluated via an I-optimal design.

Results

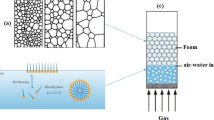

Multi-factor analysis of variance (ANOVA) indicated that rotation speed and L/S ratio dominated the granulation process and had the most significant effects on granule size distribution (GSD). The largest granule mass median diameter was obtained at the lowest rotation speed and highest L/S ratio. The granulation mechanism underlying this continuous process was examined using a wetting and nucleation regime map. For the cases studied here, the mechanical dispersion regime controlled the formation of granule nuclei, leading to a broad GSD and a limited growth ratio.

Similar content being viewed by others

References

Meng W, Kotamarthy L, Panikar S, Sen M, Pradhan S, Marc M, et al. Statistical analysis and comparison of a continuous high shear granulator with a twin screw granulator: effect of process parameters on critical granule attributes and granulation mechanisms. Int J Pharm. 2016;513(1–2):357–75.

Koynov S, Wang Y, Redere A, Amin P, Emady HN, Muzzio FJ, et al. Measurement of the axial dispersion coefficient of powders in a rotating cylinder: dependence on bulk flow properties. Powder Technol. 2016;292:298–306.

Faig JJ, Moretti A, Joseph LB, Zhang Y, Nova MJ, Smith K, et al. Biodegradable kojic acid-based polymers: controlled delivery of bioactives for melanogenesis inhibition. Biomacromolecules. 2016;

Oka S, Kašpar O, Tokárová V, Sowrirajan K, Wu H, Khan M, et al. A quantitative study of the effect of process parameters on key granule characteristics in a high shear wet granulation process involving a two component pharmaceutical blend. Adv Powder Technol. 2015;26(1):315–22.

Oka S, Emady H, Kašpar O, Tokárová V, Muzzio F, Štěpánek F et al. The effects of improper mixing and preferential wetting of active and excipient ingredients on content uniformity in high shear wet granulation. Powder Technol 2015; 278(0):266–277.

Ennis BJ. Agglomeration and size enlargement—session summary paper. Powder Technol. 1996;88(3):203–25.

Hapgood KP, Litster JD, Smith R. Nucleation regime map for liquid bound granules. AICHE j. 2003;49(2):350–61.

Iveson SM, Litster JD, Hapgood K, Ennis BJ. Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol. 2001;117(1–2):3–39.

Vervaet C, Remon JP. Continuous granulation in the pharmaceutical industry. Chem Eng Sci. 2005;60(14):3949–57.

Zhang Y, Chan JW, Moretti A, Uhrich KE. Designing polymers with sugar-based advantages for bioactive delivery applications. J Control Release. 2015;219:355–68.

Keleb EI, Vermeire A, Vervaet C, Remon JP. Twin screw granulation as a simple and efficient tool for continuous wet granulation. Int J Pharm. 2004;273(1–2):183–94.

Gamlen MJ, Eardley C. Continuous extrusion using a raker perkins Mp50 (multipurpose) extruder. Drug dev Ind Pharm. 1986;12(11–13):1701–13.

Lindberg NO, Tufvesson C, Olbjer L. Extrusion of an effervescent granulation with a twin screw extruder, Baker Perkins Mpf 50-D. Drug dev Ind Pharm. 1987;13(9–11):1891–913.

Djuric D, Kleinebudde P. Continuous granulation with a twin-screw extruder: impact of material throughput. Pharm dev Technol. 2010;15(5):518–25.

El Hagrasy AS, Hennenkamp JR, Burke MD, Cartwright JJ, Litster JD. Twin screw wet granulation: influence of formulation parameters on granule properties and growth behavior. Powder Technol. 2013;238:108–15.

Thompson MR, Sun J. Wet granulation in a twin-screw extruder: implications of screw design. J Pharm Sci-Us. 2010;99(4):2090–103.

Hapgood KP, Litster JD, Biggs SR, Howes T. Drop penetration into porous powder beds. J Colloid Interf Sci. 2002;253(2):353–66.

Pandey P, Tao J, Chaudhury A, Ramachandran R, Gao JZ, Bindra DS. A combined experimental and modeling approach to study the effects of high-shear wet granulation process parameters on granule characteristics. Pharm dev Technol. 2013;18(1):210–24.

Badawy SIF, Narang AS, LaMarche K, Subramanian G, Varia SA. Mechanistic basis for the effects of process parameters on quality attributes in high shear wet granulation. Int J Pharm. 2012;439(1–2):324–33.

Ritala M, Holm P, Schaefer T, Kristensen HG. Influence of liquid bonding strength on power-consumption during granulation in a high shear mixer. Drug dev Ind Pharm. 1988;14(8):1041–60.

Iveson SM, Litster JD. Liquid-bound granule impact deformation and coefficient of restitution. Powder Technol. 1998;99(3):234–42.

Iveson SM, Neil PW. Brittle to plastic transition in the dynamic mechanical behavior of partially saturated granular materials. J Appl Mech-T Asme. 2004;71(4):470–5.

Tardos GI, Khan MI, Mort PR. Critical parameters and limiting conditions in binder granulation of fine powders. Powder Technol. 1997;94(3):245–58.

Iveson SM, Litster JD. Growth regime map for liquid-bound granules. AICHE j. 1998;44(7):1510–8.

Pathare PB, Bas N, Fitzpatrick JJ, Cronin K, Byrne EP. Effect of high shear granulation process parameters on the production of granola cereal aggregates. Biosyst Eng. 2011;110(4):473–81.

Wang SL, Ye GH, Heng PWS, Ma MX. Investigation of high shear wet granulation processes using different parameters and formulations. Chem Pharm Bull. 2008;56(1):22–7.

Ohno I, Hasegawa S, Yada S, Kusai A, Moribe K, Yamamoto K. Importance of evaluating the consolidation of granules manufactured by high shear mixer. Int J Pharm. 2007;338(1–2):79–86.

Liu LX, Litster JD, Iveson SM, Ennis BJ. Coalescence of deformable granules in wet granulation processes. AICHE j. 2000;46(3):529–39.

Plank R, Diehl B, Grinstead H, Zega J. Quantifying liquid coverage and powder flux in high-shear granulators. Powder Technol. 2003;134(3):223–34.

Kayrak-Talay D, Litster JD. A priori performance prediction in pharmaceutical wet granulation: testing the applicability of the nucleation regime map to a formulation with a broad size distribution and dry binder addition. Int J Pharm. 2011;418(2):254–64.

Kayrak-Talay D, Dale S, Wassgren C, Litster J. Quality by design for wet granulation in pharmaceutical processing: assessing models for a priori design and scaling. Powder Technol. 2013;240:7–18.

Litster JD, Hapgood KP, Michaels JN, Sims A, Roberts M, Kameneni SK. Scale-up of mixer granulators for effective liquid distribution. Powder Technol. 2002;124(3):272–80.

Chan EL, Reynolds GK, Gururajan B, Salman AD, Hounslow MJ. Blade-granule bed stress in a cylindrical high-shear granulator: variability studies. Chem Eng Technol. 2012;35(8):1435–47.

Litster JD, Hapgood KP, Michaels JN, Sims A, Roberts M, Kameneni SK, et al. Liquid distribution in wet granulation: dimensionless spray flux. Powder Technol. 2001;114(1–3):32–9.

Ax K, Feise H, Sochon R, Hounslow M, Salman A. Influence of liquid binder dispersion on agglomeration in an intensive mixer. Powder Technol. 2008;179(3):190–4.

Schaafsma SH, Vonk P, Kossen NWF. Fluid bed agglomeration with a narrow droplet size distribution. Int J Pharm. 2000;193(2):175–87.

Acknowledgements

The authors would like to acknowledge the financial support from National Science Foundation Engineering Research Center on Structured Organic Particulate Systems.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, W., Oka, S., Liu, X. et al. Effects of Process and Design Parameters on Granule Size Distribution in a Continuous High Shear Granulation Process. J Pharm Innov 12, 283–295 (2017). https://doi.org/10.1007/s12247-017-9288-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-017-9288-7