Abstract

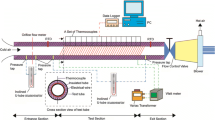

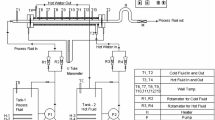

Enhancement techniques based on artificial roughness are used in numerous applications of heat exchangers. Heat exchange devices are essential components in complex engineering systems, such as industrial energy generation and energy conversion. In this study, a short helical plate was used to enhance heat transfer in a horizontal circular annulus tube. Experiments and CFD were performed to study the heat transfer effect of the helical plate, and Teflon and brass materials were used for the helical plate. Uniform heat flux was considered, and particle image velocimetry (PIV) was used for comparisons. The Nusselt number profiles increased steeply around the Teflon helical plate and decreased suddenly to 1.0 along the test section.

Similar content being viewed by others

References

B. B. Gupta, J. A. Howell, D. Wu and R. W. Field, A helical baffle for cross-flow microfiltration, J. of Membrane Science, 99 (1995) 31–42.

J. J. van Dijk, A. C. Hoffmann, D. Cheesman and J. G. Yates, The influence of horizontal internal baffles on the flow pattern in dense fluidized beds by X-ray investigation, Power Technology, 98 (3) (1998) 273–278.

S. Eiamsa-ard and P. Promvonge, Enhancement of heat transfer in a tube with regularly-spaced helical tape swirl generators, Solar Energy, 78 (4) (2005) 483–494.

M. M. Elias, I. M. Shahrul, I. M. Mahbubul, R. Saidur and N. A. Rahim, Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid, International J. of Heat and Mass Transfer, 70 (2014) 289–297.

B. Farajollahi, S. Gh. Etemad and M. Hojjat, Heat transfer of nanofluids in a shell and tube heat exchanger, InternationalJ. of HeatandMass Transfer, 53 (2010) 12–17.

A. Zamzamian, S. Nasseri Oskouie, A. Doosthoseini, A. Joneidi and M. Pazouki, Experimental investigation of forced convection heat transfer coefficient in nanofluids of A12O3/EG and CuO/EG in a double pipe and plate heat exchanger under turbulent flow, Experimental Thermal and Fluid Science, 35 (3) (2010) 495–502.

W. Duangthongsuk and S. Wongwises, Heat transfer enhancement and pressure drop characteristics of TiO2-water nanofluids in a double pipe counterflow heat exchanger, J. of Heat and Mass Transfer, 52 (2009) 2059–2067.

M. N. Pantzali, A. A. Mouza and S. V. Paras, Investigating the efficacy of nanofluids as coolant in plate heat exchanger (PHE), Chemical Engineering Science, 64 (14) (2009) 3290–3300.

H. Maddah, M. Alizadeh, N. Ghasemi and S. R. W. Arwi, Experimental study of A1203 water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes, International J. of Heat Transfer andMass Transfer, 78 (2014) 1042–1054.

T.-H. Chang, H.-S. Lee, K.-J. Oh, C.-H. Lee and D.-H. Doh, Velocity profiles between two baffles in a horizontal circular tube, J. of Thermal Science, 23 (6) (2014) 544–551.

T.-H. Chang, H.-S. Lee, K.-J. Oh and C.-H. Lee, Study on velocity profiles around the spiral baffle plates in a horizontal circular tube without inner tubes, The 13th Asian Symposium on Visualization, Novosibirsk, Russia, June 22–26 (2015).

T. H. Chang, K.-J. Oh, H.-S. Lee and C.-H. Lee, Study on velocity characteristics around continuous helical baffles with and without one inner tube, The 6th Asian Joint Workshop on Thermophysics and Fluid Science, Guilin, China, September 20–23 (2016).

M. M. Rashidi, M. Nasiri, M. S. Shadloo and Z. Yang, Entropy generation in a circular tube heat exchanger using nan-ofluids: Effects of different modeling approaches, Heat Transfer Engineering, 38 (9) (2017) 853–866.

H. Yang, J. Wen, X. Gu, K. Li, S. Wang and Y. Li, Improvements on flow distribution and heat transfer performance of plate-fin heat exchangers by qusai-S type header configuration, Heat Transfer Engineering, 38 (18) (2017) 1547–1560.

Acknowledgments

This research was supported by the ReSEAT program funded by the Ministry of Science, ICT and Future Planning through the National Research Foundation of Korea and the Korea Lottery Commission grants.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Recommended by Guest Editor Maenghyo Cho.

Tae-Hyun Chang is an Emeritus Professor at the Division of Mechanical Engineering at Kyungnam University in Korea. After his retirement from Kyungnam University, he has worked for the Korean Institute of Science and Technology Information as a Senior Research Fellow. His M.Sc. is from Dong A University in Korea and his Ph.D. from University of Wales (Swansea, UK). His field of interest is heat transfer enhancement in heat exchangers using several kinds of nanofluids.

Kwon-Soo Lee was educated at Yungnam University in Korea. He worked for Hyundai Rotem as a mechanical engineer. He obtained his Ph.D. at the Division of Mechanical Engineering at Kyungnam University in Korea. He currently works at the International University of Korea as a Professor. His major research field is convection heat transfer with and without swirl flow.

Ki-Won Chang is a Research Engineer at Dong Hwan Ind. Corp in Korea. He completed his M.S.(2007) at the Division of Mechanical Engineering at Kyungnam University in Korea. His research focus is on the design and development of air-conditioning systems of larger cars.

Sangmin Kim is a CFD engineer at Taesung Software & Engineering in South Korea. He received his Master’s degree from Chungnam National University in 2011. He has performed various field simulations since 2011 using ANSYS products. For ANSYS users, he is in charge of training, technical support, and consulting in Taesung Software & Engineering.

Chang-Hoan Lee is a Senior Researcher at the Korea Institute of Science and Technology Information, Seoul, South Korea. He received his Ph.D. in Mechanical Engineering from the University of Seoul in 2007 and M.S. in the same field from Yonsei University, South Korea. His current research focus is on the heat transfer of fluid mechanics, and the prediction of emerging technologies from science big data.

Rights and permissions

About this article

Cite this article

Chang, TH., Lee, KS., Chang, KW. et al. Heat transfer characteristics of a short helical plate in a horizontal circular tube. J Mech Sci Technol 33, 3613–3620 (2019). https://doi.org/10.1007/s12206-019-0701-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0701-7