Abstract

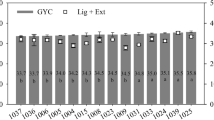

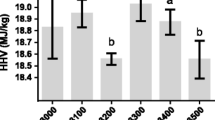

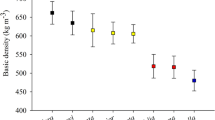

About 11% of the world’s primary energy consumption comes from biomass. However, a continuing material deficit indicates the need to find suitable timber for use as bioenergy. In this context, this study aims to determine some chemical and energetic properties, wood density, and fiber features of 10 Hevea brasiliensis clones, including Eucalyptus tereticornis and E. pellita species, to understand how the characteristics of studied woods might interfere with higher heating value (HHV) and determine if these woods and their residues would present potential for bioenergy. In general, HHV results corroborate those in the literature, e.g., E. pellita (16,502 kJ kg−1) lower value, and MT45 H. brasiliensis clone (19,757 kJ kg−1) higher value, and woods with higher extractive contents and lignin content, but lower holocellulose content, of wood pulp, in addition to denser woods with longer fibers and thicker walls, are woods considered to have higher heating values and, hence, indicated as potential woods for use in bioenergy. However, it is suggested that wood characteristics should be analyzed together to determine the most suitable material for use in bioenergy since a high value of one factor influencing HHV would not, in and of itself, establish suitability of the wood for bioenergy. Nonetheless, all wood samples could have their waste exploited for bioenergy since they range from 16,502 kJ kg−1 in E. pellita to 19,757 kJ kg−1 in the MT45 clone of H. brasiliensis.

Similar content being viewed by others

References

Vale AT, Gentil LV (2008) Produção e uso energético de biomassa e resíduos agroflorestais. Tecnologias aplicadas ao setor madeireiro III Jerônimo Monteiro-ES 12:196–246. https://doi.org/10.5902/198050981702

Silva MG, Numazawa S, Araujo MM, Nagaishi TYR, Galvão GR (2007) Carvão de resíduos de indústria madeireira de três espécies florestais exploradas no município de Paragominas, PA. Acta Amazonica 2007 37(1):61–70. https://doi.org/10.1590/S0044-59672007000100007

Nahuz M (2007) Atividades industriais, usos e aplicações de madeiras no Brasil, com ênfase em Pinus e Eucalyptus. Tecnologias aplicadas ao setor madeireiro Jerônimo Monteiro–ES:159–208

IEA. Instituto de Economia Agrícola (2014) Metodologia de custos operacionais de rentabilidade e procedimentos do estudo, produção planta / ano. Available at: <http://www.iea.sp.gov.br/out/LerTexto.php?codTexto=13598>>. Access on 27/ago/2017

Gonçalves ECP, da Seringueira SCT (2010) A cultura da seringueira para o Estado de São Paulo. Campinas, CATI (Manual, 72), 90p

Martins A L (2010) Produção de mudas de qualidade: fundamental para formação do seringal. Casa da Agricultura, São Paulo, ano 13, n. 4: 14-15

Schneider VE, Peresin D, Trentin A C, Bortolin T A, Sambuichi R H R (2012) Diagnóstico dos Resíduos Orgânicos do Setor Agrossilvopastoril e Agroindústrias Associadas, Relatório de pesquisa. Brasília, DF: IPEA. Available at: <http://hbjunior19.files. wordpress.com/2012/11/120917_relatorio_residuos_organicos.pdf>. Access on: dez. 2012

Dias AC, Arroja L (2012) Environmental impacts of eucalypt and maritime pine wood production in Portugal. J Clean Prod 37:368–376. https://doi.org/10.1016/j.jclepro.2012.07.056

Quirino WF, Vale AT, Andrade AD, Abreu VLS, Azevedo ADS (2005) Poder calorífico da madeira e de materiais ligno-celulósicos. Revista da madeira 89(100):e106

Gurgel-Garrido LMA, Siqueira ACMF, Cruz SF, Romanelli RC, Ettori LG, Crestana CSM, Sato AS (1997) Programa de melhoramento genético florestal do Instituto Florestal. IF Série Registros 18:1–53

Cordeiro I, Secco R (2015) Hevea in Lista de Espécies da Flora do Brasil. Jardim Botânico do Rio de Janeiro. Available at: <http://floradobrasil.jbrj.gov.br/jabot/floradobrasil/FB22704>. Access on: 10/02/2019

Brink M (2008) Eucalyptus tereticornis Sm. In: Louppe D, Oteng-Amoako AA, Brink M (eds) Plant Resources of Tropical Africa, 7:262–274

Fern K, Fern A, Morris R, (2014) Useful tropical plants database. Available at: http://tropical.theferns.info/ access on: 10/02/2019

Santos HD, Jacomine PKT, Anjos LD, Oliveira VD, Oliveira JD, Coelho MR, Cunha TD (2006) Sistema brasileiro de classificação de solos. Rio de Janeiro 412

Zanata M (2009) Efeito do manejo na qualidade do solo e da água em microbacias hidrográficas, Batatais, SP. 2009. xiii, 79 f. Dissertação (mestrado) - Universidade Estadual Paulista, Faculdade de Ciências Agrárias e Veterinárias. Available at: <http://hdl.handle.net/11449/96987> Access on: 10/02/2019

American Society for Testing and Materials. D5865–98: standard test method for gross calorific value of coal and coke. Philadelphia, 1998. 10p

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. In: Ross R. (ed.). Wood handbook – wood as an engineering material. 100th ed. Madison: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, 2010. p. 4-1-4-19

Ruzin SE (1999) Plant microtechnique and microscopy, vol 198. Oxford University Press, New York

Wheeler EA, Baas P, Gasson PE (Eds.) (1989) IAWA list of microscopic features for hardwood identification, 219–332

Ratnasingam J, Scholz F (2009) Rubberwood: an industrial perspective. World Resources Institute, p 74

Franz FPK, Kuenzi EW, Stamm AJ (1975) Principles of wood science and technology. Springer-Verlag

Phyllis ECN (2012) Database for biomass and waste. Energy Research Centre of the Netherlands. Avaible in: https://phyllis.nl/

Alakangas E (2005) Properties of wood fuels used in Finland. VTT Processes, Project report PRO2/P2030/05 (Project C5SU00800), Technical Research Centre of Finland, Jyväskylä

Huhtinen, M. (2006). Wood biomass as a fuel. Finland. Available at: https://www.hnee.de/_obj/CD8F42A0-B396-40E7-9F36 FF60A55DEFF7/outline/5Eures_- WoodPropertiesPDF.pdf

Dietenberger M, Hasburgh L (2016) Wood products thermal degradation and fire. Reference Module in Materials Science and Materials Engineering:1–8

Telmo C, Lousada J (2011) Heating values of wood pellets from different species. Biomass Bioenergy 35:2634–2639. https://doi.org/10.1016/j.biombioe.2011.02.043

Cardoso, DBOS (2019) Bowdichia in Flora do Brasil 2020 em construção. Jardim Botânico do Rio de Janeiro. Available at: <http://floradobrasil.jbrj.gov.br/reflora/floradobrasil/FB22835>. Access on: 05 Fev. 2019

Tan AG (1989) Pyrolysis of rubberwood-a laboratory study. J Trop For Sci 1(3):244–254

Werther J, Saenger M, Hartge EU, Ogada T, Siagi Z (2000) Combustion of agricultural residues. Prog Energy Combust Sci 26(1):1–27. https://doi.org/10.1016/S0360-1285(99)00005-2

Müzel SD, De Oliveira KA, Hansted FAS, Prates GA, Goveia D (2014) Wood calorific power from Eucalyptus grandis and Hevea brasiliensis species. Revista Brasileira de Engenharia de Biossistemas 8(2):166–172

Pereira JCD, Sturion JA, Higa AR, Higa RCV, Shimizu JY (2000) Características da madeira de algumas espécies de eucalipto plantadas no Brasil. Embrapa Florestas, Colombo, 113p

Kumar R, Pandey KK, Chandrashekar N, Mohan S (2010) Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J For Res 21(4):514–516. https://doi.org/10.1007/s11676-010-0108-x

Lachowicz H, Sajdak M, Paschalis-Jakubowicz P, Cichy W, Wojtan R, Witczak M (2018) The influence of location, tree age and forest habitat type on basic fuel properties of the wood of the silver birch (Betula pendula Roth.) in Poland. BioEnergy Research, 1–14. https://doi.org/10.1007/s12155-018-9926-z

Günther B, Gebauer K, Barkowski R, Rosenthal M, Bues CT (2012) Calorific value of selected wood species and wood products. Eur J Wood Wood Prod 70(5):755–757. https://doi.org/10.1007/s00107-012-0613-z

Bufalino L, de Paula PT, Couto AM, Nassur OAC, de Sá VA, Trugilho PF, Mendes LM (2012) Caracterização química e energética para aproveitamento da madeira de costaneira e desbaste de cedro australiano. Pesquisa Florestal Brasileira 32(70):129–121. https://doi.org/10.4336/2012.pfb.32.70.13

Castro JF, Parra C, Yáñez-S M, Rojas J, Teixeira Mendonça R, Baeza J, Freer J (2013) Optimal pretreatment of Eucalyptus globulus by hydrothermolysis and alkaline extraction for microbial production of ethanol and xylitol. Ind Eng Chem Res 52(16):5713–5720. https://doi.org/10.1021/ie301859x

Demirbaş A (2001) Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers Manag 42(11):1357–1378. https://doi.org/10.1016/S0196-8904(00)00137-0

Gomes Costa T, Bianchi ML, de Paula Protásio T, Trugilho PF, Júnior Pereira A (2014) Qualidade da madeira de cinco espécies de ocorrência no cerrado para produção de carvão vegetal. Cerne, 20(1). https://doi.org/10.1590/S0104-77602014000100005

Gani A, Naruse I (2007) Efeito do conteúdo de celulose e lignina sobre as características de pirólise e de combustão para diversos tipos de biomassa. Renew Energy 32(4):649–661. https://doi.org/10.1016/j.renene.2006.02.017

Neto Oliveira SND, Reis Ferreira MDG, Neves Lima JC (2003) Produção e distribuição de biomassa em Eucalyptus camaldulensis Dehn em resposta à adubação e ao espaçamento Revista Árvore, 27(1)

Artemio CP, Maginot NH, Serafín CU, Rahim FP, Guadalupe RQJ, Fermín CM (2018) Physical, mechanical and energy characterization of wood pellets obtained from three common tropical species. PeerJ 6:e5504. https://doi.org/10.7717/peerj.5504

Hoadley RB (2000) Understanding wood: a craftsman’s guide to wood technology. Taunton press

Naji HR, Sahri MH, Nobuchi T, Bakar ES (2013) Radial variation of wood cell features under different stocking densities management of two new clones of rubberwood (Hevea brasiliensis). J Wood Sci 59(6):460–468. https://doi.org/10.1007/s10086-013-1357-z

Sreevani P, Rao RV (2013) Variation in basic density, fibre and vessel morphology of Eucalyptus tereticornis Sm. clones. Int J Sci Technol Res 2(7):99–102

Lukmandaru G, Zumaini UF, Soeprijadi D, Nugroho WD, Susanto M (2016) Chemical properties and fiber dimension of Eucalyptus pellita from the 2nd generation of progeny tests in Pelaihari, South Borneo, Indonesia. J Korean Wood Sci Technol 44(4):571–588. https://doi.org/10.5658/WOOD.2016.44.4.571

Acknowledgments

The authors thank Sonia G. Campião and Juraci A. Barbosa from the Instituto Florestal, São Paulo, Brasil; Erick P. Amorim from the Programa de Pós-Graduação em Planejamento e Uso de Recursos Renováveis - UFSCAR/Sorocaba, Brasil; and Regina M. Buch from the Laboratório de Química, Celulose e Energia, Escola Superior de Agricultura Luiz de Queiroz (ESALQ) and Universidade de São Paulo (USP), Piracicaba, Brasil, for laboratory assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Menucelli, J.R., Amorim, E.P., Freitas, M.L.M. et al. Potential of Hevea brasiliensis Clones, Eucalyptus pellita and Eucalyptus tereticornis Wood as Raw Materials for Bioenergy Based on Higher Heating Value. Bioenerg. Res. 12, 992–999 (2019). https://doi.org/10.1007/s12155-019-10041-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-019-10041-6