Abstract

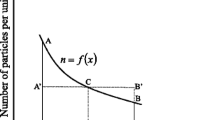

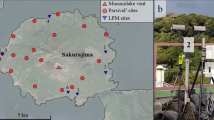

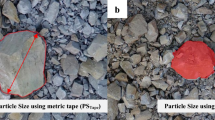

A number of methods and machines based on these methods have been developed to determine particle size. Image analysis has been used for many years to determine the particle size distribution of materials especially relatively coarse sized, in large quantities, or spread over a large area where screen analysis cannot be applied. The three-dimensional data supporting the classical digital image analysis method working with two-dimensional data were recently introduced to increase the accuracy of the analysis results. In this study, the piles formed by aggregate mixtures with known particle size distributions were scanned with terrestrial laser scanner to obtain point cloud data and then the particle size distributions of these piles were determined with the help of the algorithm given here. An important step of the algorithm used is to determine the local minimum points on the scan surfaces. Three different mathematical methods have been used at this stage. When the particle size distribution curves obtained by sieve analysis of the mixtures are taken into consideration, the most accurate result is obtained in the morphological reconstruction approach. It has been concluded that the particle size distributions of the aggregate piles can be reliably determined with the use of the point cloud data and the algorithm using that approach.

Similar content being viewed by others

References

Barkley T, Carter R (1999) Evaluation of optical sizing methods. Proc. 25th Ann. Conf. On explosives and blasting technique, Nashville, Tennessee, USA: 305–324

Bartley DA, Trousselle R (1998) Davey-tronic, digital detonator testing in a vibration sensitive environment. Proc. 24th Ann. Conf. On explosives and blasting technique, New Orleans, Louisiana, USA: 247–261

Bedair, A (1996) Digital image analysis of rock fragmentation from blasting. Ph.D. thesis, Department of Mining and Metallurgical Engineering, McGill University, Montreal, Quebec

Bouajila A, Bartolacci G, Koch N, Cayouette J and Cote C (2000) Toward the improvement of primary grinding productivity and energy investigation consumption efficiency. Mine to Mill 2000, Finland: 5

Chiappetta RF, Treleaven T, Smith JD (1998) History and expansion of the Panama Canal. Proc. 24th Ann. Conf. On explosives and blasting technique, New Orleans, Louisianna, USA: 1–34

Chung SH (1996) Experience in fragmentation control. Measurement of Blast Fragmentation, Ed by J.A. Franklin & T. Katsabanis. Rotterdam: Balkema: 247–252

Chung SH Noy MJ (1996) Experience in fragmentation control. Proceedings of the FRAGBLAST 5 workshop on measurement of blast fragmentation, Montreal, Quebec, Canada, 23–24 Aug., 1996: 247–252

Dahlhielm S (1996) Industrial applications of image analysis. The IPACS system. Measurement of Blast Fragmentation, Ed by J.A. Franklin & T. Katsabanis. Rotterdam: Balkema: 59–65

Dance A (2001) The importance of primary crushing in mill feed size optimization. SAG 2001: 13

Downs DC, Kettunen BE (1996) On-line fragmentation measurment utilizing the CIAS system. Proceedings of the FRAGBLAST 5 workshop on measurement of blast fragmentation, Montreal, Quebec, Canada, 23–24 Aug., 1996: 79–82

Elliott R, Ethier R, Levaque J, (1999) Lafarge Exshaw finer fragmentation study. Proc. 25th Ann. Conf. On explosives and blasting technique, Nashville, Tennessee, USA, Vol. II: 333–354

Eloranta J, Palangio T, Palangio TC, Workman l (2007) Size Matters on the Mesabi Range. Gen. Proc. 33rd Ann. Conf. of ISEE on Expl.& Blasting Tech., Jan. 28–31, Nashville,1: 387–399

Engin IC (2009) A practical method of bench blast-ing design for desired fragmentation based on digital image processing technique and Kuz-ram model. In J.A. Sanchidrian (ed.), Fragmentation by Blasting, Proc. of the 9th Int. Symp. on Rock Fragmentation by Blasting—Fragblast 9, Sept. 13–17, 2009, Granada, Spain: 257-264

Ethier R, Levaque JG, Wilson M (1999) Achieving finer fragmentation and proving the cost benefits. Fragblast 1999. Johannesburg, South Africa, Institute of Mining and Metallurgy: 99–102

Fernlund JMR (2005a) Image analysis method for determining 3-D size distribution of coarse aggregates. Bull Eng Geol Environ 64:159–166

Fernlund JMR (2005b) Image analysis method for determining 3-D shape of coarse aggregate. Cem Concr Res 35:1629–1637

Fernlund JMR (2005c) 3-D image analysis size and shape method applied to the evaluation of the Los Angeles test. Eng Geol 77:57–67

Fernlund JMR, Zimmerman RW, Kragic D (2007) Influence of volume/mass on grain-size curves and conversion of image—analysis size to sieve size. Eng Geo 90:124–137

Gallagher E (1976) Optoelectronic coarse particle size analysis for industrial measurement and control. Ph.D. thesis, University of Queensland, Dept. of Mining and Metallurgical Engineering

Hayakawaa Y, Oguchib T (2005) Evaluation of gravel sphericity and roundness based on surface-area measurement with a laser scanner. Comput Geosci 31:735–741

Kleine TH, Cameron AR (1996) Blast Fragmentation measurement using GoldSize. Proceedings of the FRAGBLAST 5 Workshop on Measurement of Blast Fragmentation, Montreal, Quebec, Canada, 23–24 Aug., 1996: 83–89

Ko YD, Shang H (2011) A neural network-based soft sensor for particle size distribution using distribution using image analysis. Powder Technol 212:359–366

Kwan AKH, Mora CF, Chan HC (1999) Particle shape analysis of coarse aggregate using digital image processing. Cem Concr Res 29:1403–1410

Lanaro F, Tolppanen P (2002) 3D characterization of coarse aggregates. Eng Geol 65:17–30

Lang TB (1990) Measurement of the size distribution of rock on a conveyor belt using machine vision. Ph.D. thesis, the Faculty of Engineering, University of the Witwatersrand, Johannesburg

Lee JRJ, Smith ML, Smith LN (2007) A new approach to the three-dimensional quantification of angularity using image analysis of the size and form of coarse aggregates. Eng Geol 91:254–264

Liao CW, Tarng YS (2009) On-line automatic optical inspection system for coarse particle size distribution. Powder Technol 189:508–513

Lin CL, Miller JD (1993) The development of a PC image-based on-line particle size analyzer. Minerals & Metallurgical Processing, No 2: 29–35

Lindqvist JE, Åkesson U (2001) Image analysis applied to engineering geology, a lit-erature review. Bull Eng Geol Environ 60:117–122

Lindström H (2010) Rock properties measurement using image processing. TRITA-LWR Master's thesis, 10: 28

Maerz NH (1998) Aggregate sizing and shape determination using digital image processing. Center for Aggregates Research (ICAR) sixth annual symposium proceedings, St. Louis, Missouri, April 19-20, 195–203

Maerz NH (2001) Automated online optical sizing analysis. SAG 2001: 250–269

Maerz NH (2004) Technical and computational aspects of the measurement of aggre-gate shape by digital image analysis. J Comput Civ Eng 18:10–19

Maerz NH, Palangio TW (2004) Post-muckpile, pre-primary crusher, automated blast fragmentation sizing. Fragblast 8(2):119–136

Maerz NH, Zhou W (1998) Optical digital fragmentation measuring systems - inherent sources of error. Fragblast 2(4):415–431

Maerz NH and Zhou W (2000) Calibration of optical digital fragmentation measuring systems,Fragblast, 4(2):126–138

Maerz NH, Palangio TC and Franklin JA (1996) WipFrag image based granulometry system. Proceedings of the FRAGBLAST 5 Workshop on Measurement of Blast Fragmentation, Montreal, Quebec, Canada, 23–24 Aug., 91–99

Maerz NH, Palangio TC, Palangio TW, Elsey K (2007) Optical sizing analysis of blasted rock: lessons learned. Vienna Conference Proceedings, P. Moser et al.: 75–82

McDermott C, Hunter GC, Miles NJ (1989) The application of image analysis to the measurement of blast fragmentation. Symp. Surface mining-future concepts, Nottingham University. Marylebone Press, Manchester, pp 103–108

Mora CF, Kwan AKH (2000) Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem Concr Res 30:351–358

Mora CF, Kwan AKH, Chan HC (1998) Particle size distribution analysis of coarse aggregate using digital image processing. Cem Concr Res 28(6):921–932

Nyberg L, Carlsson O, Schmidtbauer B (1982) Estimation of the size distribution of fragmented rock in ore mining through automatic image processing. Proc. IMEKO 9th World Congress, May, Vol. V/III: 293–301

Ozen M, Guler M (2014) Assessment of optimum threshold and particle shape parameter for the image analysis of aggregate size distribution of concrete sections. Opt Lasers Eng 53:122–132

Palangio TC, Maerz NH (1999) Case studies using the WipFrag image analysis system. FRAGBLAST 6, 6th Int. Symp. For Rock Fragmentation By Blasting, Johannesburg, South Africa: 117–120

Palangio TW, Palangio TC, Maerz NH, (2005) Advanced optical blast fragmentation sizing and tracking. 2005 European Fed. of Explosives Engineers Brighton Conf. Proc.: 259–267

Rao C, Tutumluer E, Stefanski JA (2001) Coarse aggregate shape and size properties using a new image analyzer. ASTM Journal of Testing and Evaluation 29:79–89

Roberts A (2001) Coarse aggregate shape and size properties using a new image analyzer. ASTM J. Test. Eval., 29: 79–89

Sarathy MO (2000) optimum blasting in surface mines—Major issues. Proc. Sem. on Blasting Objectives and Risk Management, Hyderabad, 13–14 July: 1–29

Schleifer J., Tessier B (2002) Fragmentation assessment using the FragScan system: quality of a blast, Fragblast, December 2002. Taylor & Francis, 6, 3–4: 321–331

Schwanghart W (2008) Curvature-MatLab function, Mathworks web https://www.mathworks.com/matlabcentral/fileexchange/19185-curvature/content/curvature.m. Accessed 08 June 2018

Surfer (2017) Surfer® User’s guide, contouring and 3D surface mapping for scientists and engineers. Golden Software

Tafesse S (2010) Physical properties of coarse particles in till coupled to bedrock composition based on new 3D image analysis method, TRITA-LWR.LIC 2047, Licentiate thesis

Tafesse S, Fernlund JMR, Bergholm F, Arvidsson M (2008) New method for 3-D size measurements of particles using image analysis. The 33rd International Geological Congress, Oslo, Norway

Tafesse S, Fernlund JMR, Bergholm F, Arvidsson M (2009) New methods to analyze glacial till clasts roundness and texture. The 27th IAS Meeting in Alghero, Italy

Tafesse S, Fernlund JMR, Bergholm F (2012) Digital sieving-Matlab based 3-D image analysis. Eng Geol 137-138:74–84

Taylor MA (2002) Quantitative measures for shape and size of particles. Powder Technol 124:94–100

Thomas GB Jr, Weir MD, Hass JR, Giordano FR (2004) Thomas' Calculus (11th edition), Pearson

Thurley, MJ (2002) Three dimensional data analysisfortheseparationandsizing of rockpiles in mining. Doctor of Philosophy Dissertation, MonashUniversity, Electrical&Computer Systems Engineering, 193

Thurley, MJ (2011) Automated online measurement of limestone particle size distributions using 3D range data, J. Process Control, Special Issue on Automation in Mining, Minerals and Metal Processing 21(2):254–262

Tutumluer E, Pan T, Carpenter SH (2005) Investigation of Aggregate Shape Effects on Hot Mix Performance Using an Image Analysis Approach. Civil Engineering Studies, Transportation Engineering University, Illinois, Urbana-Champaign

Wang WX (1995) Automatic image analysis of rock particles from a moving Conveyor Belt. Licentiate thesis. Dept. of Civil and Environmental Engineering, Royal Institute of Technology, Stockholm, Sweden

Wang W (2008) Rock Particle Image Segmentation and Systems, Pattern Recognition Techniques,Technology and Applications, Peng-Yeng Yin (Ed.), InTech, Vienna, Austria

Wang W, Bergholm F (1995) Moment based edge density for automatic size inspection. Proceedings of the 9th Scandinavian Conference on Image Analysis, Uppsala, Sweden

Zeng S, Wang Y, Wang WX (1992) Study on the techniques of photo -image analysis for rock fragmentation by blasting. Proc. for third period of Sino-Swedish joint research on science and technology of metallurgy. Publishing House of Metallurgical Industry, China: 103–115

Zhou H, Wu J, Zhang J (2010) Digital Image Processing: Part II, Bookboon

Acknowledgements

The funding was provided by The Scientific and Technological Research Council of Turkey to realize this study is gratefully acknowledged. The author is grateful to Dr. Norbert H. Maerz for his support in carrying out this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by: H. Babaie

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Engin, I.C. Comparison of the different mathematical methods performed in determining the size distribution of aggregates using LiDAR point cloud data and suggested algorithm. Earth Sci Inform 12, 365–380 (2019). https://doi.org/10.1007/s12145-019-00384-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12145-019-00384-1