Abstract

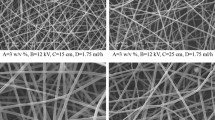

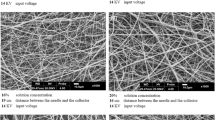

In this research study, a photo-electrospinning device was designed and manufactured to produce nanofibres (NFs) by using an optical polymerization method. For this purpose, an electrospinning machine was designed and optimized. Various parameters such as voltage, speed of collector and distance were investigated on the uniformity and diameter of polycaprolactone fibres. Therefore, a Taguchi experimental design was used to optimize the diameter of the fibres. Nine experiments were conducted using scanning electron microscopy to study the surface morphology of the obtained fibres. The best conditions for producing NFs include: voltage \(=\) 15 V, speed of collector \(=\) 600 rpm and distance \(=\) 20 cm.

Similar content being viewed by others

References

Yu Z, Xu C, Yuan K, Gan X, Zhou H, Wang X et al 2018 Ceram. Int.44 9454

Kikuchi T, Nishinaga O, Nakajima D, Kawashima J, Natsui S, Sakaguchi N et al 2014 Sci. Rep.4 7411

Al-Saleh M H and Sundararaj U 2009 Carbon47 2

Ozkan T, Naraghi M and Chasiotis I 2010 Carbon48 239

Liu C, Tan Y, Liu Y, Shen K, Peng W, Niu X et al 2016 J. Energy Chem.25 587

Na K H, Kim W T, Park D C, Shin H G, Lee S H, Park J et al 2018 Thin Solid Films660 358

Pal D B, Singh P and Mishra P K 2017 J. Alloys Compd.694 10

Cramariuc B, Cramariuc R, Scarlet R, Rozemarie Manea L, Lupu L and Cramariuc O 2013 J. Electrostat.71 189

Kong L and Ziegler G R 2014 Food Hydrocolloids36 20

Gee S, Johnson B and Smith A L 2018 J. Membr. Sci.563 804

Nakhowong R and Chueachot R 2017 J. Alloys Compd.715 390

Panda P K 2013 Ceram. Int.39 4523

Zu-Sheng H, Ling-Hua T, Xiao-Miao C, Fa-Yin J, San-Jiu Y and Fu-Ming X 2011 Mater. Lett.65 1079

Subbiah T, Bhat G S and Tock R W 2005 J. Appl. Polym. Sci.96 557

Beigmoradi R, Samimi A and Mohebbi-Kalhori D 2018 Polymer143 271

Oktay B, Kayaman-Apohan N and Erdem-Kuruca S 2014 Mater. Sci. Eng.64 012011

Karuppuswamy P, Reddy Venugopal J, Navaneethan B, LuwangLaiva A and Ramakrishna S 2015 Mater. Lett.141 180

Yao Y, Wei H, Wang J, Lu H, Leng J and Hui D 2015 Composites, Part B83 264

Doustgani A, Vasheghani-Farahani E, Soleimani M and Hashemi-Najafabadi S 2012 Composites, Part B43 1830

Liu S, He Z, Xu G and Xiao X 2014 Mater. Sci. Eng. C44 201

Zhang H, Niu Q, Wang N, Nie J and Ma G 2015 Eur. Polym. J.71 440

Niu Q, Zeng L, Mu X, Nie J and Ma G 2016 J. Ind. Eng. Chem.34 337

Gupta P, Scott T R, Long T E and Wilkes G L 2004 Macromolecules37 9211

Wang H, Feng Y, An B, Zhang W, Sun M, Fang Z et al 2012 J. Mater. Sci.: Mater. Med.23 1499

Sohrabi M R, Mirzabeygi V and Davallo M 2018 Spectrochim. Acta, Part A201 306

Mou Y, Zhou L, You X, Lu Y, Chen W and Zhao X 2017 Chemom. Intell. Lab. Syst.160 13

Kavaklioglu K 2018 J. Build. Eng.18 467

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Madani, F., Didekhani, R., Sohrabi, M.R. et al. Modelling experimental parameters for fabrication of nanofibres using Taguchi optimization by an electrospinning machine. Bull Mater Sci 43, 159 (2020). https://doi.org/10.1007/s12034-020-02138-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02138-y