Abstract

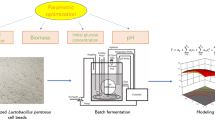

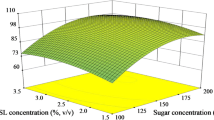

In this study, Box-Behnken design was applied to optimize the initial concentrations of 4 cations for L-lactic acid production from fructose by homologous batch fermentation of Lactobacillus pentosus cells. The optimum initial cation concentrations were obtained as 6.542 mM Mg2+, 3.765 mM Mn2+, 2.397 mM Cu2+, and 3.912 mM Fe2+, respectively. The highest L-lactic acid yield and productivity were obtained as 0.935 ± 0.005 g/g fructose and 1.363 ± 0.021 g/(L × h), respectively, with a maximum biomass concentration of 7.97 ± 0.17 g/L. The effectiveness of the optimization by Box-Behnken design was confirmed based on the small errors between predicted results and experimental results shown as 0.3%, − 0.2%, and − 1.2%, respectively. The quadratic models with high accuracy and reliability can be applied to mathematically forecasted the fermentation performance. After the optimization, the lactic acid yield and productivity were significantly improved by 3.7% and 21.0%, respectively.

Similar content being viewed by others

Data Availability

All data and materials are available.

Abbreviations

- ANOVA:

-

Analysis of variance

- ATCC:

-

American Type Culture Collection

- DOE:

-

Design of experiment

- EMP:

-

EmbdenMeyerhoff-Parnas

- LA:

-

Lactic acid

- LAB:

-

Lactic acid bacteria

- MRS:

-

de Man, Rogosa and Sharpe

- 1H NMR:

-

Proton nuclear magnetic resonance

- OD:

-

Optical density

- PEP:

-

Phosphoenolpyruvate

- PK:

-

Pentose phosphoketolase

- PLA:

-

Polylactic acid

- RSM:

-

Response surface methodology

References

Laopaiboon, P., Thani, A., Leelavatcharamas, V., & Laopaiboon, L. (2010). Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresource Technology, 101(3), 1036–1043. https://doi.org/10.1016/j.biortech.2009.08.091.

Zhao, Z., Xie, X., Wang, Z., Tao, Y., Niu, X., Huang, X., Liu, L., & Li, Z. (2016). Immobilization of Lactobacillus rhamnosus in mesoporous silica-based material: an efficiency continuous cell-recycle fermentation system for lactic acid production. Journal of Bioscience and Bioengineering, 121(6), 645–651. https://doi.org/10.1016/j.jbiosc.2015.11.010.

Abdel-Rahman, M. A., Tashiro, Y., & Sonomoto, K. (2013). Recent advances in lactic acid production by microbial fermentation processes. Biotechnology Advances, 31(6), 877–902. https://doi.org/10.1016/j.biotechadv.2013.04.002.

Li, Y., & Cui, F. (2010). Microbial lactic acid production from renewable resources. In O. Singh & S. Harvey (Eds.), Sustainable Biotechnology. Dordrecht: Springer. https://doi.org/10.1007/978-90-481-3295-9_11.

Cronewitz, T., Munir, M., Schneider, B., & Sentko, A. (2000). Fructose. In Ullmann's Encyclopedia of Industrial Chemistry. https://doi.org/10.1002/14356007.a12_047.

Bustos, G., Moldes, A. B., Cruz, J. M., & Domínguez, J. M. (2005). Influence of the metabolism pathway on lactic acid production from hemicellulosic trimming vine shoots hydrolyzates using Lactobacillus pentosus. Biotechnology Progress, 21(3), 793–798. https://doi.org/10.1021/bp049603v.

Zhu, Y., Wang, Z., & Zhang, L. (2019). Optimization of lactic acid fermentation conditions for fermented tofu whey beverage with high-isoflavone aglycones. LWT, 111, 211–217. https://doi.org/10.1016/j.lwt.2019.05.021.

Chen, C. C., Lan, C. C., Pan, C. L., Huang, M. Y., Chew, C. H., Hung, C. C., Chen, P. H., & Lin, H. T. V. (2019). Repeated-batch lactic acid fermentation using a novel bacterial immobilization technique based on a microtube array membrane. Process Biochemistry, 87, 25–32. https://doi.org/10.1016/j.procbio.2019.09.016.

Radosavljević, M., Pejin, J., Pribić, M., Kocić-Tanackov, S., Mladenović, D., Djukić-Vuković, A., & Mojović, L. (2020). Brewing and malting technology by-products as raw materials in L-(+)-lactic acid fermentation. Journal of Chemical Technology & Biotechnology, 95(2), 339–347. https://doi.org/10.1002/jctb.5878.

González-Leos, A., Bustos, M. G., Rodríguez-Castillejos, G. C., Durán, L. R., & Del Ángel, J. D. Á. (2020). Kinetics of lactic acid fermentation from sugarcane bagasse by lactobacillus pentosus. Revista Mexicana de Ingeniería Química, 19(1), 377–386. https://doi.org/10.24275/rmiq/Alim618.

Wu, C., Li, T., Qi, J., Jiang, T., Xu, H., & Lei, H. (2020). Effects of lactic acid fermentation-based biotransformation on phenolic profiles, antioxidant capacity and flavor volatiles of apple juice. LWT, 122, 109064. https://doi.org/10.1016/j.lwt.2020.109064.

Markkinen, N., Laaksonen, O., Nahku, R., Kuldjärv, R., & Yang, B. (2019). Impact of lactic acid fermentation on acids, sugars, and phenolic compounds in black chokeberry and sea buckthorn juices. Food Chemistry, 286, 204–215. https://doi.org/10.1016/j.foodchem.2019.01.189.

Garman, J., Coolbear, T., & Smart, J. (1996). The effect of cations on the hydrolysis of lactose and the transferase reactions catalysed by β-galactosidase from six strains of lactic acid bacteria. Applied Microbiology and Biotechnology, 46(1), 22–27. https://doi.org/10.1007/s002530050778.

Cocaign-Bousquet, M., Garrigues, C., Loubiere, P., & Lindley, N. D. (1996). Physiology of pyruvate metabolism in Lactococcus lactis. Antonie Van Leeuwenhoek, 70(2–4), 253–267. https://doi.org/10.1007/BF00395936.

Shockey, W. L., & Barta, A. L. (1991). Effect of salt on fermentation of alfalfa. 1. Treatment with potassium chloride. Journal of Dairy Science, 74(1), 155–159. https://doi.org/10.3168/jds.S0022-0302(91)78156-3.

Vriesekoop, F., Rasmusson, M., & Pamment, N. B. (2002). Respective effects of sodium and chloride ions on filament formation and growth and ethanol production in Zymomonas mobilis fermentations. Letters in Applied Microbiology, 35(1), 27–31. https://doi.org/10.1046/j.1472-765X.2002.01137.x.

McMurtrie, E. K., Johanningsmeier, S. D., Breidt Jr., F., & Price, R. E. (2019). Effect of brine acidification on fermentation microbiota, chemistry, and texture quality of cucumbers fermented in calcium or sodium chloride brines. Journal of Food Science, 84(5), 1129–1137. https://doi.org/10.1111/1750-3841.14600.

Deng, W., Wang, P., Wang, B., Wang, Y., Yan, L., Li, Y., Zhang, Q., Cao, Z., & Wang, Y. (2018). Transformation of cellulose and related carbohydrates into lactic acid with bifunctional Al (III)–Sn (II) catalysts. Green Chemistry, 20(3), 735–744. https://doi.org/10.1039/C7GC02975F.

Wang, J., Huang, J., Laffend, H., Jiang, S., Zhang, J., Ning, Y., Fang, M., & Liu, S. (2020). Optimization of immobilized Lactobacillus pentosus cell fermentation for lactic acid production. Bioresources and Bioprocessing, 7(1), 1–14. https://doi.org/10.1186/s40643-020-00305-x.

Holzgrabe, U. (2010). Quantitative NMR spectroscopy in pharmaceutical applications. Progress in Nuclear Magnetic Resonance Spectroscopy, 57(2), 229–240. https://doi.org/10.1016/j.pnmrs.2010.05.001.

Buyondo, J. P., & Liu, S. (2013). Unstructured kinetic modeling of batch production of lactic acid from hemicellulosic sugars. Journal of Bioprocess Engineering and Biorefinery, 2(1), 40–45. https://doi.org/10.1166/jbeb.2013.1037.

Cazor, A., Deborde, C., Moing, A., Rolin, D., & This, H. (2006). Sucrose, glucose, and fructose extraction in aqueous carrot root extracts prepared at different temperatures by means of direct NMR measurements. Journal of Agricultural and Food Chemistry, 54(13), 4681–4686. https://doi.org/10.1021/jf060144i.

Wang, J., Huang, J., Jiang, S., Zhang, J., Zhang, Q., Ning, Y., Fang, M., & Liu, S. (2020). Parametric optimization and kinetic study of l-lactic acid production by homologous batch fermentation of Lactobacillus pentosus cells. Biotechnology and Applied Biochemistry. https://doi.org/10.1002/bab.1994.

Martinez, F. A. C., Balciunas, E. M., Salgado, J. M., González, J. M. D., Converti, A., & de Souza Oliveira, R. P. (2013). Lactic acid properties, applications and production: a review. Trends in Food Science & Technology, 30(1), 70–83. https://doi.org/10.1016/j.tifs.2012.11.007.

Gao, C., Ma, C., & Xu, P. (2011). Biotechnological routes based on lactic acid production from biomass. Biotechnology Advances, 29(6), 930–939.

Agrawal, D. C., Yadav, A., Kesarwani, R., Srivastava, O. N., & Kayastha, A. M. (2020). Immobilization of fenugreek β-amylase onto functionalized graphene quantum dots (GQDs) using Box-Behnken design: its biochemical, thermodynamic and kinetic studies. International Journal of Biological Macromolecules, 144, 170–182. https://doi.org/10.1016/j.ijbiomac.2019.12.033.

Wang, J., Huang, J., Guo, H., Jiang, S., Zhang, J., Ning, Y., Fang, M. and Liu, S., (2020). Optimization of immobilization conditions for Lactobacillus pentosus cells. Bioprocess and Biosystems Engineering, pp.1-9. https://doi.org/10.1007/s00449-020-02305-9

Lu, Z., Fleming, H. P., Mc Feeters, R. F., & Yoon, S. A. (2002). Effects of anions and cations on sugar utilization in cucumber juice fermentation. Journal of Food Science, 67(3), 1155–1161. https://doi.org/10.1111/j.1365-2621.2002.tb09469.x.

Archibald, F. S., & Fridovich, I. (1981). Manganese and defenses against oxygen toxicity in Lactobacillus plantarum. Journal of Bacteriology, 145(1), 442–451.

Lyttleton, J. W. (1960). Stabilization by manganous ions of ribosomes from embryonic plant tissue. Nature, 187(4742), 1026–1027.

Vardanyan, Z., & Trchounian, A. (2012). Fe (III) and Fe (II) ions different effects on Enterococcus hirae cell growth and membrane-associated ATPase activity. Biochemical and Biophysical Research Communications, 417(1), 541–545. https://doi.org/10.1016/j.bbrc.2011.11.159.

Costas, M., Mehn, M. P., Jensen, M. P., & Que, L. (2004). Dioxygen activation at mononuclear nonheme iron active sites: enzymes, models, and intermediates. Chemical Reviews, 104(2), 939–986. https://doi.org/10.1021/cr020628n.

Xu, E., Wu, Z., Jiao, A., & Jin, Z. (2018). Effect of exogenous metal ions and mechanical stress on rice processed in thermal-solid enzymatic reaction system related to further alcoholic fermentation efficiency. Food Chemistry, 240, 965–973. https://doi.org/10.1016/j.foodchem.2017.08.033.

Poyner, R. R., Laughlin, L. T., Sowa, G. A., & Reed, G. H. (1996). Toward identification of acid/base catalysts in the active site of enolase: comparison of the properties of K345A, E168Q, and E211Q variants. Biochemistry, 35(5), 1692–1699. https://doi.org/10.1021/bi952186y.

Lew, L. C., Choi, S. B., Tan, P. L., & Liong, M. T. (2014). Mn2+ and Mg2+ synergistically enhanced lactic acid production by Lactobacillus rhamnosus FTDC 8313 via affecting different stages of the hexose monophosphate pathway. Journal of Applied Microbiology, 116(3), 644–653. https://doi.org/10.1111/jam.12399.

Lüthi, D., Günzel, D., & McGuigan, J. A. (1999). Mg-ATP binding: its modification by spermine, the relevance to cytosolic Mg2+ buffering, changes in the intracellular ionized Mg2+ concentration and the estimation of Mg2+ by 31P-NMR. Experimental Physiology, 84(2), 231–252. https://doi.org/10.1111/j.1469-445X.1999.01799.x.

Sissi, C., & Palumbo, M. (2009). Effects of magnesium and related divalent metal ions in topoisomerase structure and function. Nucleic Acids Research, 37(3), 702–711. https://doi.org/10.1093/nar/gkp024.

Raccach, M. (1985). Manganese and lactic acid bacteria. Journal of Food Protection, 48(10), 895–898.

Holm, R. H., Kennepohl, P., & Solomon, E. I. (1996). Structural and functional aspects of metal sites in biology. Chemical Reviews, 96(7), 2239–2314. https://doi.org/10.1021/cr9500390.

Ye, T., Li, X., Zhang, T., Su, Y., Zhang, W., Li, J., Gan, Y., Zhang, A., Liu, Y., & Xue, G. (2018). Copper (II) addition to accelerate lactic acid production from co-fermentation of food waste and waste activated sludge: understanding of the corresponding metabolisms, microbial community and predictive functional profiling. Waste Management, 76, 414–422. https://doi.org/10.1016/j.wasman.2018.03.028.

Mrvčić, J., Butorac, A., Šolić, E., Stanzer, D., Bačun-Družina, V., Cindrić, M., & Stehlik-Tomas, V. (2013). Characterization of Lactobacillus brevis L62 strain, highly tolerant to copper ions. World Journal of Microbiology and Biotechnology, 29(1), 75–85. https://doi.org/10.1007/s11274-012-1160-9.

Raccach, M., & Marshall, P. S. (1985). Effect of manganese ions on the fermentative activity of frozen-thawed lactobacilli. Journal of Food Science, 50(3), 665–668. https://doi.org/10.1111/j.1365-2621.1985.tb13768.x.

Contributions

Jianfei Wang, Shaoming Jiang, and Shijie Liu are the primary contributors of this work. Jiaqi Huang and Huanyu Guo provided important technical support for experiments and manuscript preparation. Xudong Bi, Maolin Hou, Xingyu Chen, Shibo Hou, Hebei Lin, Yuming Lu, Hujie Lv, Jinyue Qiao, and Ruiyi Yang participated in this study and supported in the manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that they have no conflict of interest.

Ethical Approval

The contents in this paper are the results of independent research. All data and pictures are authentic and reliable. In addition to the references already indicated in the text, the research results of this paper do not include any content of copyright enjoyed by others. This paper is not submitted to more than one journal for simultaneous consideration. All data and results shown in this paper has not been published.

Consent to Participate

Not applicable.

Consent to Publish

The publication of the paper has been agreed by the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Jiang, S., Huang, J. et al. Optimization of Initial Cation Concentrations for L-Lactic Acid Production from Fructose by Lactobacillus pentosus Cells. Appl Biochem Biotechnol 193, 1496–1512 (2021). https://doi.org/10.1007/s12010-021-03492-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-021-03492-1