Abstract

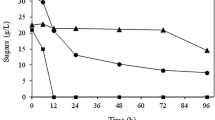

Apple pomace, an abundant accessible source of carbohydrate platform chemicals, is refractory to cellulase degradation because of the main barrier problem of pectin constitute. A rapid and portable method for the coproduction of pectin and fermentable sugars was developed using the pretreatment of acetic acid, followed by enzymatic hydrolysis. Compared with pectinase, acetic acid pretreatment provided the highest pectin yield of 19.1% and the highest enzymatic hydrolysis yield from apple pomace. The acidic pretreated apple pomace cellulose was easily and completely hydrolyzed into fermentable sugars. More than 98.2% conversion of cellulose was achieved in a batch hydrolysis using a cellulase loading of 25 FPU/g cellulose and 10% total solids without any special strategies. A mass balance analysis showed that 95.5 g pectin and 110.2 g fermentable sugars were produced from 500-g oven-dried apple pomace. The integrated process is suggestive of environment-friendly and recyclable methods for the industrial utilization of apple pomace.

Similar content being viewed by others

References

Wang, X., & Lü, X. (2014). Characterization of pectic polysaccharides extracted from apple pomace by hot-compressed water. Carbohydrate Polymers, 102, 174–184.

Wikiera, A., Mika, M., Starzyńska-Janiszewska, A., & Stodolak, B. (2016). Endo-xylanase and endo-cellulase-assisted extraction of pectin from apple pomace. Carbohydrate Polymers, 142, 199–205.

Parmar, I., & Rupasinghe, H. P. V. (2013). Bio-conversion of apple pomace into ethanol and acetic acid : enzymatic hydrolysis and fermentation. Bioresource Technology, 130, 613–620.

Vendruscolo, F., Albuquerque, P. M., Streit, F., Esposito, E., & Ninow, J. L. (2008). Apple pomace: a versatile substrate for biotechnological applications. Critical Reviews in Biotechnology, 28(1), 1–12.

Rafein, M., Hirata, S., & Ali, M. (2015). Hydrothermal pretreatment enhanced enzymatic hydrolysis and glucose production from oil palm biomass. Bioresource Technology, 176, 142–148.

Bonnin, E., Grangé, H., Lesage-meessen, L., Asther, M., & Thibault, J. (2000). Enzymic release of cellobiose from sugar beet pulp , and its use to favour vanillin production in Pycnoporus cinnabarinus from vanillic acid. Carbohydrate Polymers, 41(2), 143–151.

Liew, S. Q., Chin, N. L., & Yusof, Y. A. (2014). Extraction and characterization of pectin from passion fruit peels. Agriculture and Agricultural Science Procedia, 2, 231–236.

Liu, G., Zhang, Q., Li, H., Qureshi, A. S., Zhang, J., Bao, X., & Bao, J. (2018). Dry biorefining maximizes the potentials of simultaneous saccharification and co-fermentation for cellulosic ethanol production. Biotechnology and Bioengineering, 115(1), 60–69.

Zhang, H., Zhou, X., Xu, Y., & Yu, S. (2017). Production of xylooligosaccharides from waste xylan, obtained from viscose fiber processing, by selective hydrolysis using concentrated acetic acid. Journal of Wood Chemistry and Technology, 37, 1–9.

Luo, J., Xu, Y., & Fan, Y. (2018). Upgrading pectin production from apple pomace by acetic acid extraction. Applied Biochemistry and Biotechnology, 187, 1300–1311.

Fischer, M., & Amadò, R. (1994). Changes in the pectic substances of apples during development and postharvest ripening. Part 1: analysis of the alcohol-insoluble residue. Carbohydrate Polymers, 25(3), 161–166.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., & Crocker, D.(2012). Determination of Structural Carbohydrates and Lignin in Biomass, Laboratory Analytical Procedure (LAP): Technical Report NREL/TP-510-42618. National Renewable Energy Laboratory (NREL), U.S. Dept. of Energy, Golden, CO.

Chen, L., Zhu, J., Baez, C., Kitin, P., & Elder, T. J. (2016). Highly thermal-stable and functional cellulose nanocrystals and nanofibrils produced using fully recyclable organic acids. Green Chemistry, 18(13), 3835–3843.

Caffall, K. H., & Mohnen, D. (2009). The structure, function, and biosynthesis of plant cell wall pectic polysaccharides. Carbohydrate Research, 344(14), 1879–1900.

Han, Q., Jin, Y., Jameel, H., Chang, H., Phillips, R., & Park, S. (2014). Autohydrolysis pretreatment of waste wheat straw for cellulosic ethanol production in a co-located straw pulp mill. Applied Biochemistry and Biotechnology, 175, 1193–1210.

Zykwinska, A. W. (2005). Evidence for in vitro binding of pectin side chains to cellulose. Plant Physiology, 139(1), 397–407.

Spagnuolo, M., Crecchio, C., Pizzigallo, M. D. R., & Ruggiero, P. (1997). Synergistic effects of cellulolytic and pectinolytic enzymes in degrading sugar beet pulp. Bioresource Technology, 60(3), 215–222.

Van Dyk, J. S., Gama, R., Morrison, D., Swart, S., & Pletschke, B. I. (2013). Food processing waste: problems, current management and prospects for utilisation of the lignocellulose component through enzyme synergistic degradation. Renewable and Sustainable Energy Reviews, 26, 521–531.

Zhang, H., Xu, Y., & Yu, S. (2017). Co-production of functional xylooligosaccharides and fermentable sugars from corncob with effective acetic acid prehydrolysis. Bioresource Technology, 234, 343–349.

Yapo, B. M. (2009). Pectin quantity, composition and physicochemical behaviour as influenced by the purification process. Food Research International, 42(8), 1197–1202.

Kumar, L., Arantes, V., Chandra, R., & Saddler, J. (2012). The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility. Bioresource Technology, 103(1), 201–208.

Beukes, N., & Pletschke, B. I. (2011). Effect of alkaline pre-treatment on enzyme synergy for efficient hemicellulose hydrolysis in sugarcane bagasse. Bioresource Technology, 102(8), 5207–5213.

Hendriks, A. T. W. M., & Zeeman, G. (2009). Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresource Technology, 100(1), 10–18.

Hodge, D. B., Karim, M. N., Schell, D. J., & Mcmillan, J. D. (2008). Soluble and insoluble solids contributions to high-solids enzymatic hydrolysis of lignocellulose. Bioresource Technology, 99(18), 8940–8948.

Ismail, N. S. M., Ramli, N., Hani, N. M., & Meon, Z. (2012). Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malaysiana, 41, 41–45.

Olver, B., Van Dyk, J. S., Beukes, N., & Pletschke, B. I. (2011). Synergy between EngE, XynA and ManA from Clostridium cellulovorans on corn stalk, grass and pineapple pulp substrates. Biotechnology, 4, 187–192.

Funding

The research was supported by the National Natural Science Foundation of China (31370573). Also, the authors gratefully acknowledge financial support from the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, J., Xu, Y. Comparison of Biological and Chemical Pretreatment on Coproduction of Pectin and Fermentable Sugars from Apple Pomace. Appl Biochem Biotechnol 190, 129–137 (2020). https://doi.org/10.1007/s12010-019-03088-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03088-w