Abstract

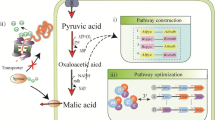

Recently, malic acid has gained attention due to its potential application in food, pharmaceutical, and medical industries. In this study, the synthetic scaffold complex strategy was employed between the two key enzymes pyruvate kinase (PykF) and malic enzyme (SfcA); SH3 ligand was attached to PykF, and the SH3 domain was attached to the C-terminus of ScfA. Synthetic scaffold systems can organize enzymes spatially and temporally to increase the local concentration of intermediates. In a flask culture, the recombinant strain harboring scaffold complex produced a maximum concentration of 5.72 g/L malic acid from 10 g/L glucose. The malic acid production was significantly increased 2.1-fold from the initial culture period. Finally, malic acid production was elevated to 30.2 g in a 5 L bioreactor from recombinant strain XL-1 blue.

Similar content being viewed by others

References

Bressler, E., Pines, O., Goldberg, I., & Braun, S. (2002). Conversion of fumaric acid to L-malic by sol-gel immobilized Saccharomyces cerevisiae in a supported liquid membrane bioreactor. Biotechnology Progress, 18, 445–450.

Chi, Z., Wang, Z. P., Wang, G. Y., Khan, I., & Chi, Z. M. (2016). Microbial biosynthesis and secretion of l-malic acid and its applications. Critical Reviews in Biotechnology, 36(1), 99–107.

Dong, X., Chen, X., Yuanyuan, Q., Wang, Y., Wang, L., Qiao, W., & Liu, L. (2016). Metabolic engineering of Escherichia coli W3110 to produce L-malic acid. Biotechnology and Bioengineering, 114, 656–664.

Duan, X., Chen, J., & Wu, J. (2013). Optimization of pullulanase production in Escherichia coli by regulation of process conditions and supplement with natural osmolytes. Bioresource Technology, 146, 379–385.

Dueber, J. E., Wu, G. C., Malmirchegini, G. R., Moon, T. S., Petzold, C. J., Ullal, A. V., Prather, K. L. J., & Keasling, J. D. (2009). Synthetic protein scaffolds provide modular control over metabolic flux. Nature Biotechnology, 27, 753–759.

Moon, S. Y., Hong, S. H., Kim, T. Y., & Lee, S. Y. (2008). Metabolic engineering of Escherichia coli for the production of malic acid. Biochemical Engineering Journal, 40, 312–320.

Moon, T. S., Dueber, J. E., Shiue, E., & Prather, K. L. (2010). Use of modular, synthetic scaffolds for improved production of glucaric acid in engineered E. coli. Metabolic Engineering, 27, 298–305.

Neubauer, A., Soini, J., Bollok, M., Zenker, M., Sandqvist, J., Myllyharju, J., & Neubauer, P. (2007). Fermentation process for tetrameric human collagen prolyl 4-hydroxylase in Escherichia coli: Improvement by gene optimisation of the PDI/β subunit and repeated addition of the inducer anhydrotetracycline. Journal of Biotechnology, 128(2), 308–321.

Pham, V. D., Lee, S. H., Park, S. J., & Hong, S. H. (2015). Production of gamma-aminobutyric acid from glucose by introduction of synthetic scaffolds between isocitrate dehydrogenase, glutamatesynthase and glutamate decarboxylase in recombinant Escherichia coli. Journal of Biotechnology, 207, 52–57.

Roa Engel, C. A., Straathof, A. J., Zijlmans, T. W., Van Gulik, W. M., & Van der Wielen, L. A. (2008). Fumaric acid production by fermentation. Applied Microbiology Biotechnology, 78, 379–389.

Rosenberg, M., Mikova, H., & Kristofikova, L. (1999). Formation of L-malic acid by yeasts of the genus dipodascus. Letters in Applied Microbiology, 29, 221–223.

Sambrook, J., & Russell, D. W. (2001). Molecular cloning: a laboratory manual, 3rd edn. New York: Cold Spring Harbor Laboratory Press.

Somasundaram, S., Tran, T. K. N., Ravikumar, S., & Hong, S. H. (2017). Introduction of synthetic protein complex between Pyrococcus horikoshii glutamate decarboxylase and Escherichia coli GABA transporter for the improved production of GABA. Biochemical Engineering Journal, 120, 1–6.

Stols, L., & Donnelly, M. I. (1997). Production of succinic acid through overexpression of NAD1-dependent malic enzyme in an Escherichia coli mutant. Applied and Environmental Microbiology, 63, 2695–2701.

Wang, Y., & Yu, O. (2012). Synthetic scaffolds increased resveratrol biosynthesis in engineered yeast cells. Journal of Biotechnology, 157, 258–260.

Werpy, T., & Petersen, G. (Eds.). (2004). Top value added chemicals from biomass. Volume I: results of screening for potential candidates from sugars and synthesis gas. Washington: US department of Energy, produced by Pacific Northwest National Laboratory (PNNL) and National Renewable Energy Laboratory (NREL).

Ye, X., Honda, K., Morimoto, Y., Okano, K., & Ohtake, H. (2013). Direct conversion of glucose to malic acid by synthetic metabolic engineering. Journal of Biotechnology, 164, 34–40.

Zelle, R. M., De Hulster, E., Van Winden, W. A., De Waard, P., Dijkema, C., Winkler, A. A., Geertman, J. M., Van Dijken, J. P., Pronk, J. T., & Van Maris, A. J. (2008). Malic acid production by Saccharomyces cerevisiae: engineering of pyruvate carboxylation, oxaloacetate reduction, and malic acid export. Applied and Environmental Microbiology, 74(9), 2766–2777.

Zhang, X., Wang, X., Shanmugam, K. T., & Ingram, L. O. (2011). L-malic acid production by metabolically engineered Escherichia coli. Applied and Environmental Microbiology, 77, 427–434.

Zhao, A., Hu, X., Li, Y., Chen, C., & Wang, X. (2016). Extracellular expression of glutamate decarboxylase B in Escherichia coli to improve gamma-aminobutyric acid production. Applied and Industrial Microbiology and Biotechnology Express, 6, 55.

Acknowledgements

This work was supported by a grant from the Next-Generation BioGreen 21 Program (SSAC, grant number: PJ01111601), Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interests

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Somasundaram, S., Eom, G.T. & Hong, S.H. Efficient Malic Acid Production in Escherichia coli Using a Synthetic Scaffold Protein Complex. Appl Biochem Biotechnol 184, 1308–1318 (2018). https://doi.org/10.1007/s12010-017-2629-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2629-7