Abstract

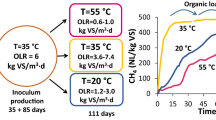

Thermophilic dry methane fermentation is advantageous for feedstock with high solid content. Distillation residue with 65.1 % moisture content was eluted from ethanol fermentation of kitchen waste and subjected to thermophilic dry methane fermentation, after adjusting the moisture content to 75 %. The effect of carbon to nitrogen (C/N) ratio on thermophilic dry methane fermentation was investigated. Results showed that thermophilic dry methane fermentation could not be stably performed for >10 weeks at a C/N ratio of 12.6 and a volatile total solid (VTS) loading rate of 1 g/kg sludge/d; however, it was stably performed at a C/N ratio of 19.8 and a VTS loading rate of 3 g/kg sludge/d with 83.4 % energy recovery efficiency. Quantitative PCR analysis revealed that the number of bacteria and archaea decreased by two orders of magnitude at a C/N ratio of 12.6, whereas they were not influenced at a C/N ratio of 19.8. Microbial community analysis revealed that the relative abundance of protein-degrading bacteria increased and that of organic acid-oxidizing bacteria and acetic acid-oxidizing bacteria decreased at a C/N ratio of 12.6. Therefore, there was accumulation of NH4 + and acetic acid, which inhibited thermophilic dry methane fermentation.

Similar content being viewed by others

References

Balat, M., Balat, H., & Oz, C. (2008). Progress in bioethanol processing. Progress in Energy and Combustion Science, 34, 551–573.

Balat, M. (2011). Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energy Conversion and Management, 52, 858–875.

De Oliveira, M. E. D., Vaughan, B. E., & Rykiel, E. J. (2005). Ethanol as fuel: energy, carbon dioxide balances, and ecological footprint. Bioscience, 55, 593–602.

Balat, M., & Balat, H. (2009). Recent trends in global production and utilization of bio-ethanol fuel. Applied Energy, 86, 2273–2282.

Tao, J., Yu, S. R., & Wu, T. X. (2011). Review of China’s bioethanol development and a case study of fuel supply, demand and distribution of bioethanol expansion by national application of E10. Biomass and Bioenergy, 35, 3810–3829.

Rabelo, S. C., Carrere, H., Maciel Filho, R., & Costa, A. C. (2011). Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept. Bioresource Technology, 102, 7887–7895.

Nishimura, H., Tan, L., Sun, Z. Y., Tang, Y. Q., Kida, K., & Morimura, S. (2016). Efficient production of ethanol from waste paper and the biochemical methane potential of stillage eluted from ethanol fermentation. Waste Management, 48, 644–651.

Koike, Y., An, M. Z., Tang, Y. Q., Syo, T., Osaka, N., Morimura, S., & Kida, K. (2009). Production of fuel ethanol and methane from garbage by high-efficiency two-stage fermentation process. Journal of Bioscience and Bioengineering, 108, 508–512.

Owamah, H. I., Dahunsi, S. O., Oranusi, U. S., & Alfa, M. I. (2014). Fertilizer and sanitary quality of digestate biofertilizer from the co-digestion of food waste and human excreta. Waste Management, 34, 747–752.

Li, Y. F., Nelson, M. C., Chen, P. H., Graf, J., Li, Y., & Yu, Z. (2015). Comparison of the microbial communities in solid-state anaerobic digestion (SS-AD) reactors operated at mesophilic and thermophilic temperatures. Applied Microbiology and Biotechnology, 99, 969–980.

Wang, Y. F., Tan, L., Wang, T., Sun, Z. Y., Tang, Y. Q., & Kida, K. (2016). Production of ethanol from kitchen waste by using flocculating Saccharomyces cerevisiae KF-7. Environmental Technology. doi:10.1080/09593330.2016.1192224.

Nelson, M. C., Morrison, H. G., Benjamino, J., Grim, S. L., & Graf, J. (2014). Analysis, optimization and verification of Illumina-generated 16S rRNA gene amplicon surveys. PloS One, 9, e94249.

Sun, Z. Y., Zhang, J., Zhong, X. Z., Tan, L., Tang, Y. Q., & Kida, K. (2016). Production of nitrate-rich compost from the solid fraction of dairy manure by a lab-scale composting system. Waste Management. doi:10.1016/j.wasman.2016.03.002.

Kida, K., Morimura, S., & Sonoda, Y. (1993). Accumulation of propionic acid during anaerobic treatment of distillery wastewater from barley-shochu making. Journal of Fermentation and Bioengineering, 75, 213–216.

Takaki, M., Tan, L., Murakami, T., Tang, Y. Q., Sun, Z. Y., Morimura, S., & Kida, K. (2015). Production of biofuels from sweet sorghum juice via ethanol–methane two-stage fermentation. Industrial Crops and Products, 63, 329–336.

Tan, L., Sun, Z. Y., Okamoto, S., Takaki, M., Tang, Y. Q., Morimura, S., & Kida, K. (2015). Production of ethanol from raw juice and thick juice of sugar beet by continuous ethanol fermentation with flocculating yeast strain KF-7. Biomass and Bioenergy, 81, 265–272.

Buswell, A., & Mueller, H. (1952). Mechanism of methane fermentation. Industrial and Engineering Chemistry, 44, 550–552.

Koch, K., Wichern, M., Lübken, M., & Horn, H. (2009). Mono fermentation of grass silage by means of loop reactors. Bioresource Technology, 100, 5934–5940.

Ioelovich, M. (2014). Waste paper as promising feedstock for production of biofuel. Journal of Scientific Research and Reports, 3, 905–916.

Wang, X. S., Song, A. D., Li, L. P., Li, X. H., Zhang, R., & Bao, J. (2011). Effect of calcium carbonate in waste office paper on enzymatic hydrolysis efficiency and enhancement procedures. Korean Journal of Chemical Engineering, 28, 550–556.

Jiang, X., Hayashi, J., Sun, Z. Y., Yang, L., Tang, Y. Q., Oshibe, H., Osaka, N., & Kida, K. (2013). Improving gas production from protein-rich distillery wastewater by decreasing ammonia inhibition. Process Biochemistry, 48, 1778–1784.

Yenigün, O., & Demirel, B. (2013). Ammonia inhibition in anaerobic digestion: a review. Process Biochemistry, 48, 901–911.

Kida, K., Shigematsu, T., Kijima, J., Numaguchi, M., Mochinaga, Y., Abe, N., & Morimura, S. (2001). Influence of Ni2+ and Co2+ on methanogenic activity and the amounts of coenzymes involved in methanogenesis. Journal of Bioscience and Bioengineering, 91, 590–595.

Hania, W. B., Godbane, R., Postec, A., Hamdi, M., Ollivier, B., & Fardeau, M. L. (2012). Defluviitoga tunisiensis gen. Nov., sp. nov., a thermophilic bacterium isolated from a mesothermic and anaerobic whey digester. International Journal of Systematic and Evolutionary Microbiology, 62, 1377–1382.

Simankova, M. V., Chernych, N. A., Osipov, G. A., & Zavarzin, G. A. (1993). Halocella cellulolytica gen. Nov., sp. nov., a new obligately cnaerobic, halophilic, cellulolytic bacterium. Systematic and Applied Microbiology, 16, 385–389.

Murray, W. D. (1986). Acetivibrio cellulosolvensis a synonym for Acetivibrio cellulolyticus: emendation of the genus Acetivibrio. International Journal of Systemtic Bacteriology, 36, 314–316.

Kuhnert, P., Capaul, S. E., Nicolet, J., & Frey, J. (1996). Phylogenetic positions of Clostridium chauvoei and Clostridium septicurn based on 16S rRNA gene sequences. International Journal of Systemtic Bacteriology, 46, 1174–1176.

Jabari, L., Gannoun, H., Cayol, J. L., Hamdi, M., Fauque, G., Ollivier, B., & Fardeau, M. L. (2012). Characterization of Defluviitalea saccharophila gen. Nov., sp. nov., a thermophilic bacterium isolated from an upflow anaerobic filter treating abattoir wastewaters, and proposal of Defluviitaleaceae fam. Nov. International Journal of Systematic and Evolutionary Microbiology, 62, 550–555.

Huang, Y., Sun, Y., Ma, S., Chen, L., Zhang, H., & Deng, Y. (2013). Isolation and characterization of Keratinibaculum paraultunense gen. Nov., sp. nov., a novel thermophilic, anaerobic bacterium with keratinolytic activity. FEMS Microbiology Letters, 345, 56–63.

Chen, S., & Dong, X. (2005). Proteiniphilum acetatigenes gen. Nov., sp. nov., from a UASB reactor treating brewery wastewater. International Journal of Systemtatic and Evolutionary Microbiology, 55, 2257–2261.

Orlygsson, J., Krooneman, J., Collins, M. D., Pascual, C., & Gottschal, J. C. (1996). Clostridium acetireducens sp. nov., a novel amino acid-oxidizing, acetate-reducing anaerobic bacterium. International Journal of Systemtic Bacteriology, 46, 454–459.

McInerney, M. J., Bryant, M. P., Hespell, R. B., & Costerton, J. W. (1981). Syntrophomonas wolfei gen. Nov. sp. nov., an anaerobic syntrophic, fatty acid-oxidizing bacterium. Applied and Environmental Microbiology, 41, 1029–1039.

Schnurer, A., Schink, B., & Svensson, B. H. (1996). Clostridium ultunense sp. nov., a mesophilic bacterium oxidizing acetate in syntrophic association with a hydrogenotrophic methanogenic bacterium. International Journal of Systematic Bacteriology, 46, 1145–1152.

Dridi, B. d., Fardeau, M. L., Ollivier, B., Raoult, D., & Drancourt, M. (2012). Methanomassiliicoccus luminyensis gen. Nov., sp. nov., a methanogenic archaeon isolated from human faeces. International Journal of Systemtatic and Evolutionary Microbiology, 62, 1902–1907.

Pullammanappallil, P. C., Chynoweth, D. P., Lyberatos, G., & Svoronos, S. A. (2001). Stable performance of anaerobic digestion in the presence of a high concentration of propionic acid. Bioresource Technology, 78, 165–169.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, YL., Tan, L., Wang, TT. et al. Thermophilic Dry Methane Fermentation of Distillation Residue Eluted from Ethanol Fermentation of Kitchen Waste and Dynamics of Microbial Communities. Appl Biochem Biotechnol 181, 125–141 (2017). https://doi.org/10.1007/s12010-016-2203-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2203-8