Abstract

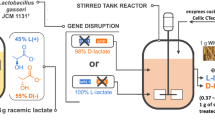

The present study aims at comparing the performances of three Lactobacillus reuteri strains (DSM 20016, DSM 17938, and ATCC 53608) in producing 3-hydroxypropionic acid (3-HP) from glycerol and at exploring inhibition phenomena during this bioconversion. Differences were highlighted between the three strains in terms of 3-HP production yield, kinetics of substrate consumption, and metabolite production. With a maximal productivity in non-optimal conditions (free pH) around 2 g.L−1.h−1 of 3-HP and 4 g.L−1.h−1 of 3-hydroxypropionaldehyde (3-HPA) depending on the strain, this study confirmed the potential of L. reuteri for the biotechnological production of 3-HP. Moreover, the molar ratios of 3-HP to 1,3-propanediol (1,3-PDO) obtained for the three strains (comprised between 1.25 and 1.65) showed systematically a higher 3-HP production. From these results, the DSM 17938 strain appeared to be the most promising strain. The impact of glycerol bioconversion on the bacteria’s physiological state (a decrease of around 40 % in DSM 17938 cells showing an enzymatic activity after 3 h) and survival (total loss of cultivability after 2 or 3 h depending on the strains) was revealed and discussed. The effect of each metabolite on L. reuteri DSM 17938 was further investigated, displaying a drastic inhibition caused by 3-HPA, while 3-HP induced lower impact and only at acidic pH.

Similar content being viewed by others

References

da Silva, G. P., Mack, M., & Contiero, J. (2009). Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol. Adv., 27, 30–39.

Pagliaro, M., Ciriminna, R., Kimura, H., Rossi, M., & Della Pina, C. (2009). Recent advances in the conversion of bioglycerol into value-added products. Eur. J. Lipid. Sci. Technol., 111, 788–799.

Bozell, J. J., & Petersen, G. R. (2010). Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green. Chem., 12, 539–554.

Zhang, D., Hillmyer, M. A., & Tolman, W. B. (2004). A new synthetic route to poly[3-hydroxypropionic acid] (P[3-HP]): ring-opening polymerization of 3-HP macrocyclic esters. Macromol., 37, 8198–8200.

Andreeßen, B., Lange, A. B., Robenek, H., & Steinbüchel, A. (2010a). Conversion of glycerol to poly(3-hydroxypropionate) in recombinant Escherichia coli. Appl. Microbiol. Biotechnol., 76, 622–626.

Andreeßen, B., & Steinbüchel, A. (2010b). Biosynthesis and biodegradation of 3-hydroxypropionate-containing polyesters. Appl. Environ. Microbiol., 76, 4919–4925.

Heinrich, D., Andreeßen, B., Madkour, M. H., Al-Ghamd, M. A., Shabbaj, I. I., & Steinbüchel, A. (2013). From waste to plastic: synthesis of poly(3-hydroxypropionate). Appl. Environ. Microbiol., 79, 3582–3589.

Gokarn, R.R., Selifonova, O.V., Jessen, H.J., Steven, J.G., Selmer, T., & Buckel, W. (2002). 3-hydroxypropionic acid and other organic compounds. Patent application no. PCT/US2002/42418 A2 (Cargill, Inc.).

Tsobanakis, P., Meng, X., & Abraham, T.W. (2009). Methods of manufacturing derivatives of beta-hydroxylic acids. Patent application no.PCT/US2009/0298144 A1 (Cargill, Inc.).

Lilga, M.A., White, J.F., Holladay, J.E., Zacher, A.H., Muzatko, D.S., & Orth, R.J. (2010). Method for conversion of β-hydroxy carbonyl compounds. Patent application no. PCT/US2007/687661 B2 (Battelle Memorial Institute).

Della Pina, C., Falletta, E., & Rossi, M. (2011). A green approach to chemical building blocks. The case of 3-hydroxypropanoic acid. Green. Chem, 13, 1624–1632.

Arceo, E., Marsden, P., Bergman, R. G., & Ellman, J. A. (2009). An efficient didehydroxylation method for the biomass-derived polyols glycerol and erythritol. Mechanistic studies of a formic acid-mediated deoxygenation. Chem. Commun., 23, 3357–3359.

Luo, L. H., Seo, J. W., Baek, J. O., Oh, B. R., Heo, S., Hong, W. K., Kim, D. H., & Kim, C. H. (2011). Identification and characterization of the propanediol utilization protein PduP of Lactobacillus reuteri for 3-hydroxypropionic acid production from glycerol. Appl. Microbiol. Biotechnol., 89, 697–703.

Kumar, V., Ashok, S., & Park, S. (2013a). Recent advances in biological production of 3-hydroxypropionic acid. Biotechnol. Adv., 31, 945–961.

Dishisha, T., Pereyra, L. P., Pyo, S. H., Britton, R. A., & Hatti-Kaul, R. H. (2014). Flux analysis of the Lactobacillus reuteri propanediol-utilization pathway for production of 3-hydroxypropionaldehyde, 3-hydroxypropionic acid and 1,3-propanediol from glycerol. Microb. Cell Fact., 13, 76–85.

Ashok, S., Raj, S. M., Rathnasingh, C., & Park, S. (2011). Development of recombinant Klebsiella pneumoniae ΔdhaT strain for the co-production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol. Appl. Microbiol. Biotechnol., 90, 1253–1265.

Kumar, V., Sankaranarayanan, M., Durgapal, M., Zhou, S., Ko, Y., Ashok, S., Sarkar, R., & Park, S. (2013b). Simultaneous production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol using resting cells of the lactate dehydrogenase-deficient recombinant Klebsiella pneumoniae overexpressing an aldehyde dehydrogenase. Bioresour. Technol., 135, 555–563.

Kwak, S., Park, Y. C., & Seo, J. H. (2013). Biosynthesis of 3-hydroxypropionic acid from glycerol in recombinant Escherichia coli expressing Lactobacillus brevis dhaB and dhaR gene clusters and E. coli K-12 aldH. Bioresour. Technol., 135, 432–439.

Kim, K., Kim, S. K., Park, Y. C., & Jin-Ho Seo, J. H. (2014). Enhanced production of 3-hydroxypropionic acid from glycerol by modulation of glycerol metabolism in recombinant Escherichia coli. Bioresour. Technol., 156, 170–175.

Jung, W. S., Kang, J. H., Chu, H. S., Choi, I. S., & Cho, K. M. (2014). Elevated production of 3-hydroxypropionic acid by metabolic engineering of the glycerol metabolism in Escherichia coli. Metabol. Eng., 23, 116–122.

Talarico, T. L., & Dobrogosz, W. J. (1990). Purification and characterization of glycerol dehydratase from Lactobacillus reuteri. Appl. Env. Microbiol., 56, 1195–1197.

Sriramulu, D. D., Liang, M., Hernandez-Romero, D., Raux-Deery, E., Lunsdorf, H., Parsons, J. B., Warren, M. J., & Prentice, M. B. (2008). Lactobacillus reuteri DSM 20016 produces cobalamin-dependent diol dehydratase in metabolosomes and metabolizes 1,2-propanediol by disproportionation. J. Bacteriol., 190, 4559–4567.

Sardari, R. R. R., Dishisha, T., Pyo, S. H., & Hatti-Kaul, R. (2013a). Improved production of 3-hydroxypropionaldehyde by complex formation with bisulfite during bio-transformation of glycerol. Biotechnol. Bioeng., 110, 1243–1248.

Sardari, R. R. R., Dishisha, T., Pyo, S. H., & Hatti-Kaul, R. (2013b). Biotransformation of glycerol to 3-hydroxypropionaldehyde: Improved production by in situ complexation with bisulfate in a fed-batch mode and separation on anion exchanger. J. Biotechnol., 168, 534–542.

Sabet-Azad, R., Linares-Pasten, J.A., Torkelson, L., Sardari, R.R.R., & Hatti-Kaul, R. (2013). Coenzyme A-acylating propionaldehyde dehydrogenase (PduP) from Lactobacillus reuteri: Kinetic characterization and molecular modeling. Enzyme Microb. Technol. 53, 235–242.

Stevens, M. J. A., Vollenweider, S., Meile, L., & Lacroix, C. (2011). 1,3-Propanediol dehydrogenases in Lactobacillus reuteri: impact on central metabolism and 3-hydroxypropionaldehyde production. Microb. Cell Fact., 10, 61–69.

Morita, H., Toh, H., Fukuda, S., Horikawa, H., Oshima, K., Suzuki, T., Murakami, M., Hisamatsu, S., Kato, Y., Takizawa, T., Fukuoka, H., Yoshimura, T., Itoh, K., O’Sullivan, D. J., McKay, L. L., Ohno, H., Kikuchi, J., Masaoka, T., & Hattori, M. (2008). Comparative genome analysis of Lactobacillus reuteri and Lactobacillus fermentum reveal a genomic island for reuterin and cobalamin production. DNA Res., 15, 151–161.

Vollenweider, S., & Lacroix, C. (2004). 3-Hydroxypropionaldehyde: applications and perspectives of biotechnological production. Appl. Microbiol. Biotechnol., 64, 16–27.

Cleusix, V., Lacroix, C., Vollenweider, S., & Le Blay, G. (2007). Inhibitory activity spectrum of reuterin produced by Lactobacillus reuteri against intestinal bacteria. BMC Microbiol., 7, 101–109.

Spinler, J. K., Taweechotipatr, M., Rognerud, C. L., Oub, C. N., Tumwasorn, S., & Versalovic, J. (2008). Human-derived probiotic Lactobacillus reuteri demonstrate antimicrobial activities targeting diverse enteric bacterial pathogens. Anaerobe, 14, 166–171.

Schaefer, L., Auchtung, T. A., Hermans, K. E., Whitehead, D., Borhan, B., & Britton, R. A. (2010). The antimicrobial compound reuterin (3-hydroxypropionaldehyde) induces oxidative stress via interaction with thiol groups. Microbiol., 156, 1589–1599.

Sebastianes, F. L. S., Cabedo, N., El Aouad, N., Valente, A. M. M. P., Lacava, P. T., Azevedo, J. L., Pizzirani-Kleiner, A. A., & Cortes, D. (2012). 3-Hydroxypropionic acid as an antibacterial agent from endophytic fungi Diaporthe phaseolorum. Curr. Microbiol., 65, 622–632.

Warnecke, T. E., Lynch, M. D., Lipscomb, M. L., & Gill, R. T. (2012). Identification of a 21 amino acid peptide conferring 3-hydroxypropionic acid stress-tolerance to Escherichia coli. Biotechnol. and Bioeng., 109, 1347–1352.

Colin, T., Bories, A., & Moulin, G. (2000). Inhibition of Clostridium butyricum by 1,3-propanediol and diols during glycerol fermentation. Appl. Microbiol. Biotechnol., 54, 201–205.

Rosander, A., Connolly, E., & Roos, S. (2008). Removal of antibiotic resistance gene-carrying plasmids from Lactobacillus reuteri ATCC 55730 and characterization of the resulting daughter strain, L. reuteri DSM 17938. Appl. Environ. Microbiol., 74, 6032–6040.

Corrieu, G., Spinnler, H.E., Jomier, Y., & Picque, D. (1988). Automated system to follow up and control the acidification activity of lactic acid starters. Patent application no. FR 2 629 612 (INRA).

Spinnler, H. E., & Corrieu, G. (1989). Automatic method to quantify starter activity based on pH measurement. J. Dairy Res., 56, 755–764.

Rault, A., Béal, C., Ghorbal, S., Ogier, J. C., & Bouix, M. (2007). Multiparametric flow cytometry allows rapid assessment and comparison of lactic acid bacteria viability after freezing and during frozen storage. Cryobiol, 55, 35–43.

Vollenweider, S., Grassi, G., König, I., & Puhan, Z. (2003). Purification and structural characterization of 3-hydroxypropionaldehyde and its derivatives. J. Agric. Food Chem., 51, 3287–3293.

Barbirato, F., Grivet, J. P., Soucaille, P., & Bories, A. (1996). 3-Hydroxypropionaldehyde, an inhibitory metabolite of glycerol fermentation to 1,3-propanediol by enterobacterial species. Appl. Environ. Microbiol., 62, 1448–1451.

Vollenweider, S., Evers, S., Zurbriggen, K., & Lacroix, C. (2010). Unraveling the HPA system: an active antimicrobial agent against human pathogens. J. Agric. Food Chem., 58, 10315–10322.

van Maris, A. J. A., Konings, W. N., van Dijken, J. P., & Pronk, J. T. (2004). Microbial export of lactic acid and 3-hydroxypropanoic acid: implications for industrial fermentation processes. Metab. Eng., 6, 245–255.

Warnecke, T. E., Lynch, M. D., Karimpour-Fard, A., Lipscomb, M. L., Handke, P., Mills, P. T., Ramey, C. J., Hoang, T., & Gill, R. T. (2010). Rapid dissection of a complex phenotype through genomic scale mapping of fitness altering genes. Metabol. Eng., 12, 241–250.

van de Guchte, M., Serror, P., Chervaux, C., Smokvina, T., Ehrlich, S. D., & Maguin, E. (2002). Stress responses in lactic acid bacteria. Antonie van Leeuwenhoek, 82, 187–216.

Acknowledgments

The authors thank Chandanie Hunter for correcting the English version of the manuscript.

Conflict of Interest

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Online Resource 1

(DOC 89 kb)

Online Resource 2

(DOC 55 kb)

Online Resource 3

(DOC 368 kb)

Online Resource 4

(DOC 374 kb)

Rights and permissions

About this article

Cite this article

Burgé, G., Saulou-Bérion, C., Moussa, M. et al. Diversity of Lactobacillus reuteri Strains in Converting Glycerol into 3-Hydroxypropionic Acid. Appl Biochem Biotechnol 177, 923–939 (2015). https://doi.org/10.1007/s12010-015-1787-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1787-8