Abstract

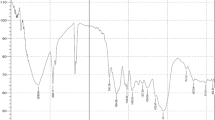

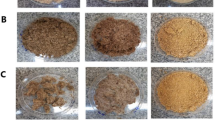

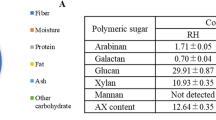

Alkali/acid-pretreated canola meal and mustard bran were subjected to endo-1,4-β-xylanase (T. longibrachiatum) hydrolysis for oligosaccharide production. Pretreatments significantly (α = 0.05) increased the relative content of pentose sugars, especially in alkali-pretreated canola meal (∼44 %) and mustard bran (∼72 %). The amounts of pentosan (g/100 g) in acid- and alkali-pretreated canola meal were 7.50 and 8.21 and in corresponding mustard bran were 8.67 and 10.39, respectively. These pretreated substrates produced a pentose content (g/100 g) of 2.10 ± 0.14 (18 h) and 2.95 ± 0.10 (24 h), respectively, during hydrolysis. As per UPLC-MS data, the main oligosaccharides in the hydrolyzates of alkali-pretreated substrates are xylo-glucuronic acid and xylobiose. The release of total phenolics of the hydrolyzates increased until 18 h irrespective of the type of substrate or pretreatment. Hydrolyzates of acid-pretreated substrates indicated more total antioxidant activity than alkali-pretreated substrates, attributed to its high phenolic content. The study suggests the potential of canola meal and mustard bran for the production of oligosaccharides, wherein the use of various combinations of cell-wall-degrading enzymes and its optimization may result in a better yield, with simultaneous production of endogenous phenolics.

Similar content being viewed by others

References

Canada’s Farm Income Forecast for 2011–2012. www.agr.gc.ca. Accessed 4 Feb 2014.

Animal Feed Resources Information System (2002). www.fao.org. Accessed 21 Dec 2013.

Zui, F., Kaneko, S., Kuno, A., Kobayashi, H., Kusakabe, I., & Mizuno, H. (2004). Journal of Biological Chemistry, 279(10), 9606–9614.

Ishihara, M., Nojiri, M., Hayashi, N., Nishimura, T., & Shimizu, K. (1997). Enzyme and Microbial Technology, 21, 170–175.

Okazaki, M., Fujikawa, S., & Mastumoto, N. (1990). Bifidobacteria and Microflora, 9, 77–86.

Nabarlatz, D., Farriol, X., & Montane, D. (2005). Industrial and Engineering Chemistry Research, 44, 7746–7755.

Moure, A., Gullon, P., Dominiguez, H., & Parajo, J. C. (2006). Process Biochemistry, 41(9), 1913–1923.

Loo, J. V., Cummings, J., Delzenne, N., Englyst, H., Franck, A., Hopkins, M., Kok, N., Macfarlane, G., Newton, D., Quigley, M., Roberfroid, M., van Vliet, T., & van den Heuvel, E. (1999). British Journal of Nutrition, 81, 121–132.

Toshio, I., Noriyoshi, I., Toshiaki, K., Toshiyuki, N. and Kunimasa, K. (1990). Japan Patent JP, 2119790.

Vazquez, M. J., Alonso, J. L., Domınguez, H., & Parajo, J. C. (2000). Trends in Food Science & Technology, 11, 387–393.

Aachary, A. A., & Prapulla, S. G. (2009). Bioresource Technology, 100(2), 991–995.

Naczk, M., Amarowicz, R., Sullivan, A., & Shahidi, F. (1998). Food Chemistry, 62(4), 489–502.

Ai, Z., Jiang, Z., Li, L., Deng, W., Kusakabe, I., & Li, H. (2005). Process Biochemistry, 40, 2707–2714.

Yang, R., Xu, S., Wang, Z., & Yang, W. (2005). LWT-Food Science and Technology, 38, 677–682.

Jiang, Z., Yang, S., Yang, Q., Li, L., & Tan, S. (2005). World Journal of Microbiology and Biotechnology, 21(6–7), 863–867.

Pramod, S. N., & Venkatesh, Y. P. (2006). Glycoconjugate Journal, 23(7–8), 481–488.

Wood, P. J., Weisz, J., & Blackwell, B. A. (1994). Cereal Chemistry, 71(3), 301–307.

Folin, O., & Ciocalteu, V. (1927). Journal of Biological Chemistry, 73, 627–650.

Reis, A., Pinto, P., Evtuguin, D. V., Neto, C. P., Domingues, P., Ferrer-Correia, A. J., & Domingues, M. R. M. (2005). Rapid Communications in Mass Spectrometry, 19, 3589–3599.

Khattab, R., Eskin, M., Aliani, M., & Thiyam, U. (2010). Journal of the American Oil Chemists Society, 87(2), 147–155.

Karakaya, S., & Simsek, S. (2011). Journal of the American Oil Chemists Society, 88, 1361–1366.

Parajo, J. C., Alonso, J. L., & Santos, V. (1995). Bioresource Technology, 51, 153–162.

Saska, M., & Ozer, E. (1995). Biotechnology and Bioengineering, 45, 517–523.

Jeong, K. J., Park, I. Y., Kim, M. S., & Kim, S. C. (1998). Applied Microbiology and Biotechnology, 50, 113–118.

Reddy, S. S., & Krishnan, C. (2013). Food Biotechnology, 27(4), 357–370.

Selvendran, R. R. (1985). Journal of Cell Science - Supplement, 2, 51–88.

Havlicek, J. E., & Samuelson, O. (1972). Carbohydrate Research, 22, 307–316.

Jacobs, A., Larsson, P. T., & Dahlman, O. (2001). Biomacromolecules, 2(3), 979–990.

Veenashri, B. R., & Muralikrishna, G. (2011). Food Chemistry, 126(3), 1475–1481.

Akpinar, O., Gunny, K., Yilmaz, Y., Levent, O., & Bostanci, S. (2010). BioResource, 5, 699–711.

Acknowledgments

This study was funded by the Agri-Food Research and Development Initiative (ARDI)-Growing Forward 1 Program and supported by the Bunge Canada, Canola Council of Canada and GS Dunn Ltd. The authors would like to thank Dr. Steve Cui and his technician Ms. Cathy Wang from the Guelph Food Research Centre, Agriculture and Agri-Food Canada for carrying out the neutral sugar analysis. The authors also would like to thank Hai Feng, Department of Human Nutritional Sciences, University of Manitoba (Winnipeg, MA, Canada) for technical assistance with UPLC-MS.

Conflict of Interest

There is no conflict of interest between the authors to declare.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, L., Scanlon, M.G., Eskin, N.A.M. et al. Effect of Pretreatments and Endo-1,4-β-Xylanase Hydrolysis of Canola Meal and Mustard Branfor Production of Oligosaccharides. Appl Biochem Biotechnol 175, 194–208 (2015). https://doi.org/10.1007/s12010-014-1253-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1253-z