Abstract

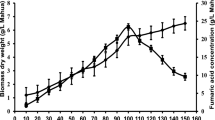

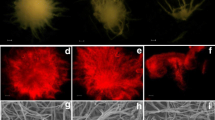

The present work explores brewery wastewater as a novel substrate for fumaric acid production employing the filamentous fungal strain Rhizopus oryzae 1526 through submerged fermentation. The effects of different parameters such as substrate total solid concentrations, fermentation pH, incubation temperature, flask shaking speed, and inoculum size on the fungal morphologies were investigated. Different morphological forms (mycelium clumps, suspended mycelium, and solid/hairy pellets) of R. oryzae 1526 were obtained at different applied fermentation pH, incubation temperature, flask shaking speed, and inoculum size. Among all the obtained morphologies, pellet morphology was found to be the most favorable for enhanced production of fumaric acid for different studied parameters. Scanning electron microscopic investigation was done to reveal the detailed morphologies of the pellets formed under all optimized conditions. With all the optimized growth conditions (pH 6, 25 °C, 200 rpm, 5 % (v/v) inoculum size, 25 g/L total solid concentration, and pellet diameter of 0.465 ± 0.04 mm), the highest concentration of fumaric acid achieved was 31.3 ± 2.77 g/L. The results demonstrated that brewery wastewater could be used as a good substrate for the fungal strain R. oryzae 1526 in submerged fermentation for the production of fumaric acid.

Similar content being viewed by others

Abbreviations

- BW:

-

brewery wastewater

- BDW:

-

biomass dry weight

- SEM:

-

scanning electron microscope

- FA:

-

fumaric acid

- rpm:

-

revolution per minute

- OD:

-

optical density

References

Xu, Q., Liu, L., & Chen, J. (2012). Microbial Cell Factories, 11, 24.

Yang, S. T., Zhang, K., Zhang, B., & Huang, H. (2011). Fumaric acid. In M. Bulter (Ed.), Moo-Young (pp. 163–167). The Netherlands: Comprehensive biotechnology.

Goldberg, I., Rokem, J. S., & Pines, O. (2006). Journal of Chemical Technology Biotechnology, 8, 1601–1611.

Sauer, M., Porro, D., Mattanovich, D., & Branduardi, P. (2008). Trends in Biotechnology, 26, 101–108.

Mrowietz, U., Christophers, E., & Altmeyep, R. (1999). British Journal of Dermatology, 141, 424–429.

Information Head Services. Report on chemical insight and forecasting: IHS Chemical. April 2010.

Beauchemin, K. A., & McGinn, S. M. (2006). Journal of Animal Science, 84, 1489–1496.

Temenoff, J. S., Kasper, F. K., & Mikos, A. G. (2007). Topics in tissue engineering. Ashammakhi, N., Reis, R., Chiellini, E (Eds). Fumarate-based macromers as scaffolds for tissue engineering applications (E-book).

Xu, Q., Li, S., Fu, Y., Tai, C., & Huang, H. (2010). Bioresource Technology, 101, 6262–6264.

Olajire, A. A. (2012). Journal of Cleaner Production. doi:10.1016/j.jclepro.2012.03.003.

European Commission. (2006). European Integrated Pollution Prevention and Control Bureau (EIPPCB) (Reference document on best available techniques (BAT) in the food, drink and milk industries). Seville: EIPPCB.

Brewers of Europe. (2002). Guidance note for establishing BAT in the brewing industry. Brussels: Brewers of Europe.

Zhou, Z., Du, G., Hua, Z., Zhou, J., & Chen, J. (2011). Bioresource Technology, 102, 9345–9349.

Li, Z., Shukla, V., Fordyce, A., Pedersen, A., Wenger, K., & Marten, M. (2000). Biotechnology Bioengineering, 70, 300–312.

Rodriguez Porcel, E., Casas Lopez, J., Sanchez Perez, J., Fernandez Sevilla, J., & Chisti, Y. (2005). Biochemical Engineering Journal, 26, 139–144.

Dhillon, G. S., Brar, S. K., & Verma, M. (2012). International Journal of Food Science and Technology, 47, 542–548.

Marshall, L. M., Orten, J. M., & Smith, A. H. (1949). Archives of Biochemistry, 24, 110–113.

Oda, Y., Yajima, Y., Kinoshita, M., & Ohnishi, M. (2003). Food Microbiology, 20, 371–375.

Gangl, I. C., Weigand, W. A., & Keller, F. A. (1990). Appl Biochemistry Biotechnology, 24–25, 663–677

Olander, A. (1929). Z. Physik. Chem. (Leipzig), Abt. A, 144, 49–72.

Meussen, B. J., de Graaff, L. H., Sanders, J. P. M., & Weusthuis, R. A. (2012). Applied Microbiology and Biotechnology, 94, 875–886.

Cui, Y. Q., Okkerse, W. J., van der Lans, R. G. J. M., & Luyben, K. C. A. M. (1998). Biotechnology Bioengineering, 60, 216–229.

Teng, Y., Xu, Y., & Wang, D. (2009). Bioprocess Biosystem Engineering, 32, 397–405.

Cui, Y. Q., Van der Lans, R. G. J. M., & Luyben, K. C. A. M. (1997). Biotechnology Bioengineering, 55, 715–726.

Braun, S., & Vecht-Lifshitz, S. E. (1991). Trends in Biotechnology, 9, 63–68.

Schugerl, K., Gerlach, S. R., & Siedenberg, D. (1998). Advances in Biochemical Engineering and Biotechnology, 60, 195–266.

Papagianni, M. (2004). Biotechnol Advances, 22, 189–259.

Nielsen, J., Johansen, C. L., Jacobsen, M., Krabben, P., & Villadsen, J. (1995). Biotechnology Progress, 11, 93–98.

Yanagita, T., & Kogane, F. (1963). Journal of General and Applied Microbiology, 9, 171–187.

Vecht-Lifshitz, S. E., Magdassi, S., & Braun, S. (1989). Biotechnology Bioengineering, 35, 890–896.

Acknowledgement

Financial support of the Natural Sciences and Engineering Research Council of Canada (discovery grant 355254), MAPAQ (no. 809051), and Ministère des Relations Internationales du Québec (coopération Paraná-Québec 2010–2012) is sincerely acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, R.K., Brar, S.K. Enhanced Fumaric Acid Production from Brewery Wastewater and Insight into the Morphology of Rhizopus oryzae 1526. Appl Biochem Biotechnol 172, 2974–2988 (2014). https://doi.org/10.1007/s12010-014-0739-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-0739-z