Abstract

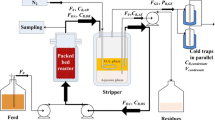

The search for renewable sources of energy has led to renewed interests on the biochemical route for the production of butanol. Butanol production suffers from several drawbacks, mainly caused by butanol inhibition to the butanol-producing microorganism which makes it economically uncompetitive against the chemical process. One possible solution proposed is the in situ recovery of acetone–butanol–ethanol (ABE). Among the in situ recovery options, membrane processes like pervaporation have a great potential. Thus, the effects of temperature, feed concentration, and ultrasound irradiation on permeate concentration and permeation flux for the recovery of butanol/ABE by pervaporation from aqueous solutions were investigated in this study. In the butanol–water system, permeate butanol concentration as well as flux increased with an increase in temperature and butanol feed concentration. When pervaporation studies with ABE–water mixture were carried out at 60 °C for 2, 4, 8, 16, and 24 h, pervaporation profile revealed an optimal permeate concentration as well as permeation flux. Applications of ultrasound irradiation on pervaporation improved permeate concentration by about 23 g/L for both butanol and ABE. Ultrasound irradiation also improved butanol and ABE mass permeation flux by about 13 and 11 %, respectively.

Similar content being viewed by others

References

Cheng, J. J., & Timilsina, G. R. (2011). Status and barriers of advanced biofuel technologies: A review. Renew Energ, 36, 3541–3549.

Srinivasan, S. (2009). The food v. fuel debate: A nuanced view of incentive structures. Renew Energ, 34, 950–954.

Hoekman, S. K. (2009). Biofuels in the U.S.—challenges and opportunities. Renew Energ, 34, 14–22.

Green, E. M. (2011). Fermentative production of butanol—the industrial perspective. Curr Opin Biotechnol, 22, 1–7.

Kharkwal, S., Karimil, I. A., Chang, M. W., & Lee, D. Y. (2009). Strain improvement and process development for biobutanol production. Recent Pat Biotechnol, 3, 202–210.

Lee, S. Y., Park, J. H., Jang, S. H., Nielsen, L. K., Kim, J. H., & Jung, K. S. (2008). Fermentative butanol production by Clostridia. Biotechnol Bioeng, 101, 209–228.

Jones, D. T., & Keis, S. (1995). Origins and relationships of industrial solvent-producing clostridial strains. FEMS Microbiol Rev, 17, 223–232.

Jones, D. T., & Woods, D. R. (1986). Acetone-butanol fermentation revisited. Microbiol Rev, 50, 484–524.

Shen, C. R., Lan, E. I., Dekishima, Y., Baez, A., Cho, K. M., & Liao, J. C. (2011). Driving forces enable high-titer anaerobic 1-butanol synthesis in Escherichia coli. Appl Environ Microbiol, 77, 2905–2915.

Oudshoorn, A., van der Wielen, L. A. M., & Straathof, A. J. J. (2009). Assessment of options for selective 1-butanol recovery from aqueous solution. Ind Eng Chem Res, 48, 7325–7336.

Shi, Z. P., Zhang, C. Y., Chen, J. X., & Mao, Z. G. (2005). Performance evaluation of acetone–butanol continuous flash extractive fermentation process. Bioprocess Biosyst Eng, 27, 175–183.

Ezeji, T. C., Qureshi, N., & Blaschek, H. P. (2007). Bioproduction of butanol from biomass: From genes to bioreactors. Curr Opin Biotechnol, 18, 220–227.

Mulder, M. H. V., & Smolders, C. A. (1984). On the mechanism of separation ethanol/water mixtures by pervaporation. Part I: calculation of concentration profiles. J Membr Sci, 17, 289–307.

Kujawski, W. (2000). Application of pervaporation and vapor, permeation in environmental protection. Pol J Environ Stud, 9, 13–26.

Baker, R. W. (2004). Membrane technology and applications (2nd ed.). Chichester: Wiley.

Vane, L. M. (2005). A review of pervaporation for product recovery from biomass fermentation processes. J Chem Technol Biotechnol, 80, 603–625.

Qureshi, N., & Blaschek, H. P. (1999). Butanol recovery from model solution/fermentation broth by pervaporation: Evaluation of membrane performance. Biomass Bioenerg, 17, 175–184.

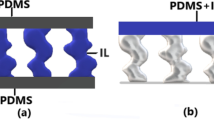

Pouget, E., Tonnar, J., Lucas, P., Lacroix-Desmazes, P., Ganachaud, F., & Boutevin, B. (2010). Well-architectured poly(dimethylsiloxane)-containing copolymers obtained by radical chemistry. Chem Rev, 110, 1233–1277.

Huang, J., & Meagher, M. M. (2001). (2001) Pervaporative recovery of n-butanol from aqueous solutions and ABE fermentation broth using thin-film silicalite-filled silicone composite membranes. J Membr Sci, 192, 231–242.

Muthukumaran, S., Kentish, S. E., Ashokkumar, M., & Stevens, G. W. (2005). Mechanisms for the ultrasonic enhancement of dairy whey ultrafiltration. J Membr Sci, 258, 106–114.

Lv, J., & Xiao, G. (2010). Ultrasound assisted pervaporation separation of pyridine/water mixtures using poly(vinyl alcohol)/polyacrylonitrile blend membranes. Chem Eng Technol, 33, 2051–2058.

McAuley, W. J., Oliveira, G., Mohammed, D., Beezer, A. E., Hadgraft, J., & Lane, M. E. (2010). Thermodynamic considerations of solvent/enhancer uptake into a model membrane. Int J Pharm, 396, 134–139.

Qureshi, N., Meagher, M. M., & Hutkins, R. W. (1999). Recovery of butanol from model solutions and fermentation broth using a silicalite/silicone membrane. J Membr Sci, 158, 115–125.

Suslick, K. S. (1990). Sonochemistry. Science, 247, 1439–1445.

Vines, R. E., Tamura, S. I., & Wolfe, J. P. (1995). Surface acoustic wave focusing and induced Rayleigh waves. Phys Rev Lett, 74, 2729–2732.

Pain, H. J. (2005). The physics of vibrations and waves (6th ed.). Chichester: Wiley.

Ghofar, A., & Kokugan, T. (2004). Pervaporation mechanism of dilute ethanol solution by hydrophobic porous membranes. Biochem Eng J, 18, 235–238.

Poling, B. E., Prausnitz, J. M., & O’Connell, J. P. (2001). The properties of gases and liquids (5th ed.). New York: McGraw-Hill.

Acknowledgments

This work was supported by the 2013 Hannam University Research Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Menchavez, R.N., Ha, S.H. Ultrasound-Enhanced Recovery of Butanol/ABE by Pervaporation. Appl Biochem Biotechnol 171, 1159–1169 (2013). https://doi.org/10.1007/s12010-013-0196-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0196-0