Abstract

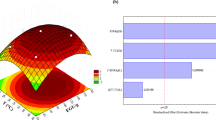

Astaxanthin is a potential high-value coproduct in an ethanol biorefinery. Three mutant strains of the astaxanthin-producing yeast Phaffia rhodozyma, which were derived from the parent strain ATCC 24202 (UCD 67-210) and designated JTM166, JTM185, and SSM19, were tested for their capability of utilizing the major sugars that can be generated from cellulosic biomass, including glucose, xylose, and arabinose, for astaxanthin production. While all three strains were capable of metabolizing these sugars, individually and in mixtures, JTM185 demonstrated the greatest sugar utilization and astaxanthin production. Astaxanthin yield by this strain (milligrams astaxanthin per gram of sugar consumed) was highest for xylose, followed by arabinose and then glucose. The kinetics of sugar utilization by strain JTM185 was studied in fermenters using mixtures of glucose, xylose, and arabinose at varied concentrations. It was found that glucose was utilized preferentially, followed by xylose, and lastly, arabinose. Astaxanthin yield was significantly affected by sugar concentrations. Highest yields were observed with sugar mixtures containing the highest concentrations of xylose and arabinose. Hydrolysates produced from sugarcane bagasse and barley straw pretreated by the soaking in aqueous ammonia method and hydrolyzed with the commercial cellulase preparation, Accellerase™ 1000, were used for astaxanthin production by the mutant strain JTM185. The organism was capable of metabolizing all of the sugars present in the hydrolysates from both biomass sources and produced similar amounts of astaxanthin from both hydrolysates, although these amounts were lower when compared to yields obtained with reagent grade sugars.

Similar content being viewed by others

References

Rausch, K. D., & Belyea, R. L. (2006). Applied Biochemistry and Biotechnology, 128, 47–86.

Bothast, R. J., & Schlicher, M. A. (2005). Applied Microbiology and Biotechnology, 67, 19–25. doi:10.1007/s00253-004-1819-8.

Nghiem, N. P., Hicks, K. B., Johnston, D. B., Senske, G., Kurantz, M., Li, M., et al. (2010). Biotechnology for Biofuels, 3, 8.

Li, X., Kim, T. H., & Nghiem, N. P. (2010). Bioresearch Technology, 101, 5910–5916. doi:10.1016/j.biortech.2010.03.015.

Nghiem, N. P., Montanti, J. M., & Johnston, D. B. (2009). Applied Biochemistry and Biotechnology, 154, 227–237.

Higuera-Ciapara, I., Felix-Valenzuela, I., & Goycoolea, F. M. (2006). Critical Reviews in Food Science and Nutrition, 46, 185–196. doi:10.1080/10408690590957188.

Palágyi, Z., Ferenczy, L., & Vágvölgyi, C. (2001). World Journal of Microbiology & Biotechnology, 17, 95–97. doi:10.1023/A:1016689512718.

An, G. H., Schuman, D. B., & Johnson, E. A. (1989). Applied and Environmental Microbiology, 55(1), 116–124.

Bon, J. A., Leathers, T. D., & Jayaswal, R. K. (1997). Biotechnological Letters, 19(2), 109–112.

Kim, T. H., Taylor, F., & Hicks, K. B. (2008). Bioresearch Technology, 99, 5694–5702. doi:10.1016/j.biortech.2007.10.055.

Acknowledgements

The authors would like to thank Mr. Gerard Senske and Ms. Jennifer Thomas of the USDA ARS ERRC for their invaluable assistance and expertise during the course of this study. The assistance of Dr. Sarah Lingle at the USDA ARS SRRC in obtaining the sugarcane bagasse is also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture.

Rights and permissions

About this article

Cite this article

Montanti, J., Nghiem, N.P. & Johnston, D.B. Production of Astaxanthin from Cellulosic Biomass Sugars by Mutants of the Yeast Phaffia rhodozyma . Appl Biochem Biotechnol 164, 655–665 (2011). https://doi.org/10.1007/s12010-011-9165-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-011-9165-7