Abstract

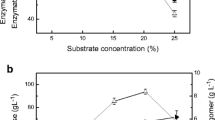

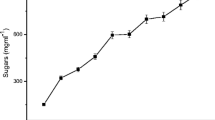

Aqueous dilute acid pretreatments of corncob were conducted using cylindrical pressure vessels in an oil bath. Pretreatments were conducted in a temperature range of 160–190 °C with acid-solution-to-solid-corncob ratio of 2. The acid concentration (v/v) in the pretreatment solution was varied from 0% to 0.7%, depending on temperature. This gives acid charge on ovendry-weight corncob of 0–2.58%. It was found that optimal pretreatment temperature is between 160 and 170 °C based on total xylose and glucose yields and thermal energy consumption in pretreatment. At 170 °C and acid charge of 2.2% on cob, total glucose yield and xylose recovery were 97% and 75%, respectively, which resulted in an overall monomeric sugar recovery of about 88%. Xylose concentration in the hydrolysate was about 12%, with xylose-to-acetic-acid ratio of 8 and to furan (furfural and hydroxymethylfurfural) of about 15.

Similar content being viewed by others

References

Becall, D. S., & Ingram, L. O. (1992). Conversion of hydrolysate of corn cobs and hulls into ethanol by recombinant Escherichia coli B containing integrated genes for ethanol production. Biotechnology Letters, 14(9), 857–862.

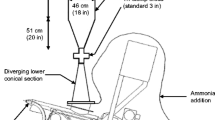

Cao, N. J., Krishnan, M. S., Du, J. X., Gong, C. S., Ho, N. W. Y., Chen, Z. D., et al. (1996). Ethanol production from corn cob pretreated by the ammonia steeping process using genetically engineered yeast. Biotechnology Letters, 18(9), 1013–1018.

Chen, M., Xia, L., & Xue, P. (2007). Enzymatic hydrolysis of corncob and ethanol production from cellulosic hydrolysate. International Biodeterioration and Biodegradation, 59, 85–89.

Chum, H. L., Johnson, D. K., Black, S. K., & Overend, R. P. (1990). Pretreatment-catalyst effects of the combined severity parameter. Applied Biochemistry and Biotechnology, 24(25), 1–14.

Foley, K. (1978). Physical properties, chemical properties and use of the Anderson's corbcob products. Maumee: The Andersons.

Inglett, G. E. (1970). Corn: Culture, processing and products. Westport: AVI.

Larsson, S., Palmqvist, E., Hahn-Hagerdal, B., Tengborg, C., Stenberg, K., Zacchi, G., et al. (1999). The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme and Microbial Technology, 24, 151–159.

Lee, J.-W., Rodrigues, R. C. L. B., & Jeffries, T. W. (2009). Simultaneous saccharification and ethanol fermentation of corn cob pretreated with oxalic acid using response surface methodology. Bioresource Technology, 100, 6307–6311.

Liu, K., Lin, L., Yue, J., Li, X., Fang, X., Zhu, M., et al. (2010). High concentration ethanol production from corncob residues by fed-batch strategy. Bioresource Technology, 101(13), 4952–4958.

Shen, Y., Zhang, Y., Ma, T., Bao, X., Du, F., Zhuang, G., et al. (2008). Simultaneous saccharification and fermentation of acid-pretretaed corncobs with recombinant Saccharomyces cerevisiae expressing beta-glucosidase. Bioresource Technology, 99, 5099–5103.

USDA. (2009). Crop production 2008 summary. Washington: National Agricultural Statistics Service.

Zhang, M., Wang, F., Su, R., Qi, W., & He, Z. (2010). Ethanol production from high dry matter corncob using fed-batch simultaneous saccharification and fermentation after combined pretreatment. Bioresource Technology, 101(13), 4959–4964.

Zhu, J. Y., & Pan, X. J. (2010). Woody biomass pretreatment for cellulosic ethanol production: Technology and energy consumption evaluation. Bioresource Technology, 101, 4992–5002.

Acknowledgments

This work was supported by the Priority Research Centers Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (Project No. 2010-0020141) to J.W. Lee and by EdeniQ under CRADA 08-RD-11111126-007 with the Forest Products Laboratory. The Tianjin Education Commission of China and the USDA Forest Service provided financial support for Wang's visiting appointment at the Forest Products Laboratory. The authors thank Frederick J. Matt of the Analytical Chemistry and Microscopy Laboratory of the USDA Forest Products Laboratory (FPL) for carrying out the carbohydrate determination and Diane Dietrich (FPL) for conducting HMF and furfural analysis.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was conducted on official government time of Zhu and Jeffries while Wang and Lee were visiting scientists at the USDA Forest Service, Forest Products Laboratory. The work is in public domain in the USA.

Rights and permissions

About this article

Cite this article

Wang, G.S., Lee, JW., Zhu, J.Y. et al. Dilute Acid Pretreatment of Corncob for Efficient Sugar Production. Appl Biochem Biotechnol 163, 658–668 (2011). https://doi.org/10.1007/s12010-010-9071-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-010-9071-4