Abstract

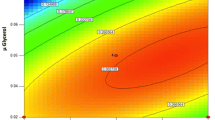

The Pichia pastoris clone producing streptokinase (SK) was optimized for its nutritional requirements to improve intracellular expression using statistical experimental designs and response surface methodology. The skc gene was ligated downstream of the native glyceraldehyde 3-phosphate dehydrogenase promoter and cloned in P. pastoris. Toxicity to the host was not observed by SK expression using YPD medium. The transformant producing SK at level of 1,120 IU/ml was selected, and the medium composition was investigated with the aim of achieving high expression levels. The effect of various carbon and nitrogen sources on SK production was tested by using Plackett–Burman statistical design and it was found that dextrose and peptone are the effective carbon and nitrogen sources among all the tested. The optimum conditions of selected production medium parameters were predicted using response surface methodology and the maximum predicted SK production of 2,136.23 IU/ml could be achieved with the production medium conditions of dextrose (x1), 2.90%; peptone (x2), 2.49%; pH, 7.2 (x3), and temperature, 30.4 (x4). Validation studies showed a 95% increase in SK production as compared to that before optimization at 2,089 IU/ml. SK produced by constitutive expression was found to be functionally active by plasminogen activation assay and fibrin clot lysis assay. The current recombinant expression system and medium composition may enable maximum production of recombinant streptokinase at bioreactor level.

Similar content being viewed by others

References

Tillett, W. S., & Garner, R. L. (1933). The Journal of Experimental Medicine, 58, 485–502. doi:10.1084/jem.58.4.485.

Banerjee, A., Chisti, Y., & Banerjee, U. C. (2004). Biotechnology Advances, 22, 287–307. doi:10.1016/j.biotechadv.2003.09.004.

Malke, H., & Ferretti, J. J. (1984). PNAS USA, 81, 3557–3561. doi:10.1073/pnas.81.11.3557.

Malke, H., Gerlach, D., Kohler, W., & Ferretti, J. J. (1984). Molecular & General Genetics, 196, 360–363. doi:10.1007/BF00328072.

Laplace, F., Muller, J., Gumpert, J., & Malke, H. (1989). FEMS Microbiology Letters, 53, 89–94. doi:10.1111/j.1574-6968.1989.tb03602.x.

Hagenson, M. J., Holden, K. A., Parker, K. A., Wood, P. J., Cruze, J. A., et al. (1989). Enzyme and Microbial Technology, 11, 650–656. doi:10.1016/0141-0229(89)90003-3.

Wong, S. L., Ruiqiong, Y., & Nathoo, S. (1994). Applied and Environmental Microbiology, 60, 517–523.

Pratap, J., Rajamohan, G., & Dikshit, K. L. (2000). Applied Microbiology and Biotechnology, 53, 469–475. doi:10.1007/s002530051643.

Kumar, R., & Singh, J. (2004). Yeast (Chichester, England), 2, 1343–1358. doi:10.1002/yea.1184.

Patrick, S. M., Fazenda, M. L., Mcneil, B., & Harvey, L. M. (2005). Yeast (Chichester, England), 22, 249–270. doi:10.1002/yea.1208.

Invitrogen Instruction Manual, A manual of methods for expression of recombinant proteins in Pichia pastoris. 2002, Catalog no. K1710–01.

Plackett, R. L., & Burman, J. P. (1946). Biometrika, 33, 305–325. doi:10.1093/biomet/33.4.305.

Akhnazarova, S., & Kafarov, V. (1982). Experiment optimization in chemistry and chemical engineering. Moscow: Mir Publications.

Myers, R. H., & Montgomery, D. C. (1995). Response Surface Methodology. In Process and Product Optimization Using Designed Experiments. New York: Wiley-Interscience.

Khuri, A. I., & Cornell, J. A. (1987). Response surfaces: design and analysis. New York: Marcel Dekker Inc.

Potumarthi, R., Gopal, M., & Jetty, A. (2008). Applied Biochemistry and Biotechnology. doi:10.1007/s12010-008-8229-9.

Dutta, J. R., Dutta, P. K., & Banerjee, R. (2004). Process Biochemistry, 39, 2193–2198. doi:10.1016/j.procbio.2003.11.009.

Ravichandra, P., Subhakar, C., Pavani, A., & Jetty, A. (2008). Bioresource Technology, 99, 1776–1786. doi:10.1016/j.biortech.2007.03.041.

Radhika, T., Kiran Kumar, D., Ravichandra, P., & Lakshmi Narasu, M. (2007). Applied Biochemistry and Biotechnology, 141, 187–201. doi:10.1007/BF02729061.

Himabindu, M., Ravichandra, P., Vishalakshi, K., & Jetty, A. (2006). Applied Biochemistry and Biotechnology, 134, 143–154. doi:10.1385/ABAB:134:2:143.

Box, G. E. P., Hunter, W. G., & Hunter, J. S. (1978). Statistics for experimenters. New York: Wiley.

Cochran, W. G., & Cox, G. M. (Eds.) (1957). In Experimental design. New York: Wiley.

Montgomery, D. (2001). Design and analysis of experiments. New York: Wiley.

Sands, D., Whitton, C. M., & Longstaff, C. (2004). Journal of Thrombosis and Haemostasis, 2(8), 1411–1415. doi:10.1111/j.1538-7836.2004.00814.x.

Couto, L. T., Donato, J. L., & de Nucci, G. (2004). Brazilian Journal of Medical and Biological Research, 37(12), 1889–1894. doi:10.1590/S0100-879X2004001200015.

Acknowledgements

This study was supported by a funding under the Technology Education Quality Improvement Program (TEQIP) by World Bank to Centre for Biotechnology, JNTU, Hyderabad. RNV acknowledges Council of Scientific and Industrial Research (CSIR) India for research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vellanki, R.N., Potumarthi, R. & Mangamoori, L.N. Constitutive Expression and Optimization of Nutrients for Streptokinase Production by Pichia pastoris Using Statistical Methods. Appl Biochem Biotechnol 158, 25–40 (2009). https://doi.org/10.1007/s12010-008-8315-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8315-z