Abstract

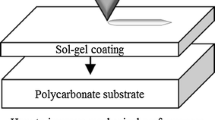

Polycarbonate (PC) has been recognized as a promising alternative for inorganic glass thanks to high optical transparency, light weight, and excellent toughness. To expand the PC applications, especially in outdoor environments, and to impart new functionalities, surface coating can be an effective approach to overcome the intrinsic drawbacks of PC, such as low hardness and poor weathering performance. Coating techniques for PC are primarily classified into the wet chemical coating of organic–inorganic hybrid networks and the gaseous vacuum deposition of inorganic materials. Parallel to the development of electrical and optical devices and energy-efficient automobiles, PC with improved electrical conductivity, antireflection, and self-cleaning has been in high demand and has been achieved by well-controlled coating technologies of programmed functional materials. This article reviews the physical properties of the coating materials used for PC with emphasis on recent progress of coating technologies.

Similar content being viewed by others

References

LeGrand, DG, Bendler, JT, Handbook of Polycarbonate Science and Technology. Marcel Dekker, New York (2000)

Jang, MJ, Park, CK, Lee, NY, “Modification of Polycarbonate with Hydrophilic/Hydrophobic Coatings for the Fabrication of Microdevices.” Sensor. Actuat. B, 193 599–607 (2014)

Zhang, Y, Trinh, KTL, Yoo, IS, Lee, NY, “One-Step Glass-Like Coating of Polycarbonate for Seamless DNA Purification and Amplification on an Integrated Monolithic Microdevice.” Sensor. Actuat. B-Chem., 202 1281–1289 (2014)

Seubert, C, Nietering, K, Nichols, M, Wykoff, R, Bollin, S, “An Overview of the Scratch Resistance of Automotive Coatings: Exterior Clearcoats and Polycarbonate Hardcoats.” Coatings, 2 221–234 (2014)

Bewilogua, K, Brauer, G, Dietz, A, Gabler, J, Goch, G, Karpuschewski, B, Szyszka, B, “Surface Technology for Automotive Engineering.” CIRP Ann. Manuf. Technol., 58 608–627 (2009)

Choi, MC, Kim, YK, Ha, CS, “Polymers for Flexible Displays: From Material Selection to Device Applications.” Prog. Polym. Sci., 33 581–630 (2008)

Schmauder, T, Nauenburg, KD, Kruse, K, “Hard Coatings by Plasma CVD on Polycarbonate for Automotive and Optical Applications.” Thin Solid Films, 502 270–274 (2006)

Charitidis, C, Laskarakis, A, Kassavetis, S, Gravalidis, C, Logothetidis, S, “Optical and Nanomechanical Study of Anti-Scratch Layers on Polycarbonate Lenses.” Superlattices Microst., 36 171–179 (2004)

Urreaga, JM, Matías, MC, Lorenzo, V, de la Orden, MU, “Abrasion Resistance in the Tumble Test of Sol-Gel Hybrid Coatings for Ophthalmic Plastic Lenses.” Mater. Lett., 45 293–297 (2000)

Katsamberis, D, Browall, K, Iacovangelo, C, Neumann Morgner, M, “Highly Durable Coatings for Automotive Polycarbonate Glazing.” Prog. Org. Coat., 34 130–134 (1998)

Samson, F, “Ophthalmic Lens Coatings.” Surf. Coat. Technol., 81 79–86 (1996)

Fukushima, M, Higuchi, K, Komori, H, Yamaya, M, Okumura, K, Chigita, K, Maruyama, Y, Takai, T, Isobe, Y, Kawamura, N, Nagai, T, “Plastic Article for Automotive Glazing.” US Patent 2012/0058347 A1 (2012)

Gasworth, SM, Peters, M, Dujardin, R, “Polycarbonate Automotive Window Panels with Coating System Blocking UV and IR Radiation and Providing Abrasion Resistant Surface.” US Patent 6,797,384 B2 (2004)

Westeppe, U, Weymans, G, Freitag, D, Idel, K-J, “Polycarbonate Mixtures in Optical Applications.” US Patent 5,132,154 (1992)

Ruhlin, R, “Method of Forming an Opthalmic Lens from a Synthetic Material Blank.” US Patent 5,100,590 (1992)

Diepens, M, Gijsman, P, “Influence of Light Intensity on the Photodegradation of Bisphenol A Polycarbonate.” Polym. Degrad. Stab., 94 34–38 (2009)

Diepens, M, Gijsman, P, “Photodegradation of Bisphenol A Polycarbonate.” Polym. Degrad. Stab., 92 397–406 (2007)

Rivaton, A, Mailhot, B, Soulestin, J, Varghese, H, Gardette, JL, “Comparison of the Photochemical and Thermal Degradation of Bisphenol-A Polycarbonate and Trimethylcyclohexane–Polycarbonate.” Polym. Degrad. Stab., 75 17–33 (2002)

Rivaton, A, “Recent Advances in Bisphenol-A Polycarbonate Photodegradation.” Polym. Degrad. Stab., 49 163–179 (1995)

Blaga, A, Yamasaki, RS, “Surface Microcracking Induced by Weathering of Polycarbonate Sheet.” J. Mater. Sci., 11 1513–1520 (1976)

Hauenstein, O, Reiter, M, Agarwal, S, Rieger, B, Greiner, A, “Bio-based Polycarbonate from Limonene Oxide and CO2 with High Molecular Weight, Excellent Thermal Resistance, Hardness and Transparency.” Green Chem., 18 760–770 (2016)

Rao, PS, Subrahmanya, S, Sathyanarayana, DN, “Polyaniline–Polycarbonate Blends Synthesized by Two Emulsion Pathways.” Synth. Met., 143 323–330 (2004)

Seguch, T, Yagi, T, Ishikawa, S, Sano, Y, “New Material Synthesis by Radiation Processing at High Temperature-Polymer Modification with Improved Irradiation Technology.” Radiat. Phys. Chem., 63 35–40 (2002)

Okamoto, M, “Synthesis and Properties of Polycarbonate-Poly(methylmethacrylate) Graft Copolymers by Polycondensation of Macromonomers.” J. Appl. Polym. Sci., 80 2670–2675 (2001)

Brinker, CJ, Sherrer, GW, Sol-Gel Science. The Physics and Chemistry of Sol-Gel Processing. Academic Press, San Diego (1990)

Ciriminna, R, Fidalgo, A, Pandarus, V, Béland, F, Ilharco, LM, Pagliaro, M, “The Sol–Gel Route to Advanced Silica-based Materials and Recent Applications.” Chem. Rev., 113 6592–6620 (2013)

Schulz, U, Kaiser, N, “Vacuum Coating of Plastic Optics.” Prog. Surf. Sci., 81 387–401 (2006)

Choy, KL, “Chemical Vapour Deposition of Coatings.” Prog. Mater. Sci., 48 57–170 (2003)

Chen, Z, Wu, LYL, “Scratch Damage Resistance of Silica-based Sol-Gel Coatings on Polymeric Substrates.” In: Friedrich, K, Schlarb, AK (eds.) Tribology of Polymeric Nanocomposites, pp. 467–511. Butterworth-Heinemann, Oxford (2013)

Yahyaei, H, Mohseni, M, “Use of Nanoindentation and Nanoscratch Experiments to Reveal the Mechanical Behavior of Sol-Gel Prepared Nanocomposite Films on Polycarbonate.” Tribol. Int., 57 144–155 (2013)

Chen, Z, Wu, LYL, Chwa, E, Tham, O, “Scratch Resistance of Brittle Thin Films on Compliant Substrates.” Mat. Sci. Eng. A Struct., 493 292–298 (2008)

Wu, LYL, Chwa, E, Chen, Z, Zeng, XT, “A Study Towards Improving Mechanical Properties of Sol-Gel Coatings for Polycarbonate.” Thin Solid Films, 516 1056–1062 (2008)

Bao, YW, Wang, W, Zhou, YC, “Investigation of the Relationship between Elastic Modulus and Hardness Based on Depth-Sensing Indentation Measurements.” Acta Mater., 52 5397–5404 (2004)

Musil, J, Kunc, F, Zeman, H, Poláková, H, “Relationships between Hardness, Young’s Modulus and Elastic Recovery in Hard Nanocomposite Coatings.” Surf. Coat. Technol., 154 304–313 (2002)

Mackenzie, JD, Bescher, EP, “Physical Properties of Sol-Gel Coatings.” J. Sol-Gel Sci. Technol., 19 23–29 (2000)

Wang, D, Bierwagen, GP, “Sol-Gel Coatings on Metals for Corrosion Protection.” Prog. Org. Coat., 64 327–338 (2009)

Schottner, G, “Hybrid Sol-Gel-Derived Polymers: Applications of Multifunctional Materials.” Chem. Mater., 13 3422–3435 (2001)

Wen, J, Vasudevan, VJ, Wilkes, GL, “Abrasion Resistant Inorganic/Organic Coating Materials Prepared by the Sol-Gel Method.” J. Sol-Gel Sci. Technol., 5 115–126 (1995)

Song, KC, Park, JK, Kang, HU, Kim, SH, “Synthesis of Hydrophilic Coating Solution for Polymer Substrate Using Glycidoxypropyltrimethoxysilane.” J. Sol-Gel Sci. Technol., 27 53–59 (2003)

Chou, TP, Cao, G, “Adhesion of Sol-Gel-Derived Organic-Inorganic Hybrid Coatings on Polyester.” J. Sol-Gel Sci. Technol., 27 31–41 (2003)

Deng, Q, Moore, RB, Mauritz, KA, “Nafion®/(SiO2, ORMOSIL, and Dimethylsiloxane) Hybrids Via In Situ Sol-Gel Reactions: Characterization of Fundamental Properties.” J. Appl. Polym. Sci., 68 747–763 (1998)

Schmidt, H, “New Type of Non-Crystalline Solids between Inorganic and Organic Materials.” J. Non-Cryst. Solids, 73 681–691 (1985)

Haas, KH, Wolter, H, “Synthesis, Properties and Applications of Inorganic-Organic Copolymers.” Curr. Opin. Solid St. M., 4 571–580 (1999)

Haas, KH, Schwab, SA, Rose, K, Schottner, G, “Functionalized Coatings Based on Inorganic-Organic Polymers(ORMOCER®s) and Their Combination with Vapor Deposited Inorganic Thin Films.” Surf. Coat. Technol., 111 72–79 (1999)

Kasemann, R, Schmidt, H, “Coatings for Mechanical and Chemical Protection Based on Organic-Inorganic Sol-Gel Nanocomposites.” New J. Chem., 18 1117–1123 (1994)

Hench, LL, West, JK, “The Sol-Gel Process.” Chem. Rev., 90 33–72 (1990)

Khramov, AN, Balbyshev, VN, Voevodin, NN, Donley, MS, “Nanostructured Sol-Gel Derived Conversion Coatings Based on Epoxy- and Amino-silanes.” Prog. Org. Coat., 47 207–213 (2003)

Hobble, D, Nacken, M, Schmidt, H, “A NMR Study on the Hydrolysis, Condensation and Epoxide Ring-Opening Reaction in Sols and Gels of the System Glycidoxypropyltrimethoxysilane-Water-Titaniumtetraethoxide.” J. Sol-Gel Sci. Technol., 12 169–179 (1998)

Mashouf, G, Ebrahimi, M, “UV Curable Urethane Acrylate Coatings Formulation: Experimental Design Approach.” Pigm. Resin Technol., 43 61–68 (2014)

Chibac, A, Melinte, V, Buruiana, T, Balan, L, Buruiana, EC, “One-Pot Synthesis of Photocrosslinked Sol-Gel Hybrid Composites Containing Silver Nanoparticles in Urethane-Acrylic Matrixes.” Chem. Eng. J., 200–202 577–588 (2012)

Sangermano, M, Foix, D, Kortaberria, G, Messori, M, “Multifunctional Antistatic and Scratch Resistant UV-Cured Acrylic Coatings.” Prog. Org. Coat., 76 1191–1196 (2013)

Nakayama, N, Hayashi, T, “Synthesis of Novel UV-Curable Difunctional Thiourethane Methacrylate and Studies on Organic-Inorganic Nanocomposite Hard Coatings for High Refractive Index Plastic Lenses.” Prog. Org. Coat., 62 274–284 (2008)

Xu, J, Pang, W, Shi, W, “Synthesis of UV-Curable Organic-Inorganic Hybrid Urethane Acrylates and Properties of Cured Films.” Thin Solid Films, 514 69–75 (2006)

Sepeur, S, Kunze, N, Werner, B, Schmidt, H, “UV Curable Hard Coatings on Plastics.” Thin Solid Films, 351 216–219 (1999)

Kim, HD, Kim, TW, “Preparation and Properties of UV-Curable Polyurethane Acrylate Ionomers.” J. Appl. Polym. Sci., 67 2153–2162 (1998)

Barletta, M, Pezzola, S, Vesco, S, Tagliaferri, V, Trovalusci, F, “Experimental Evaluation of Plowing and Scratch Hardness of Aqueous Two-Component Polyurethane (2 K-PUR) Coatings on Glass and Polycarbonate.” Prog. Org. Coat., 77 636–645 (2014)

Xu, H, Qiu, F, Wang, Y, Wu, W, Yang, D, Guo, Q, “UV-Curable Waterborne Polyurethane-Acrylate: Preparation, Characterization and Properties.” Prog. Org. Coat., 73 47–53 (2012)

Hwang, HD, Park, CH, Moon, JI, Kim, HJ, Masubuchi, T, “UV-Curing Behavior and Physical Properties of Waterborne UV-Curable Polycarbonate-Based Polyurethane Dispersion.” Prog. Org. Coat., 72 663–675 (2011)

Masson, F, Decker, C, Jaworek, T, Schwalm, R, “UV-Radiation Curing of Waterbased Urethane-Acrylate Coatings.” Prog. Org. Coat., 39 115–126 (2000)

Decker, C, Masson, F, Schwalm, R, “Weathering Resistance of Waterbased UV-Cured Polyurethane-Acrylate Coatings.” Polym. Degrad. Stab., 83 309–320 (2004)

Decker, C, Masson, F, Schwalm, R, “Dual-Curing of Waterborne Urethane-Acrylate Coatings by UV and Thermal Processing.” Macromol. Mater. Eng., 288 17–28 (2003)

Park, YJ, Lim, DH, Kim, HJ, Park, DS, Sung, IK, “UV- and Thermal-Curing Behaviors of Dual-Curable Adhesives Based on Epoxy Acrylate Oligomers.” Int. J. Adhes. Adhes., 29 710–717 (2009)

Jeon, SJ, Lee, JJ, Kim, W, Chang, TS, Koo, SM, “Hard Coating Films Based on Organosilane-Modified Boehmite Nanoparticles under UV/Thermal Dual Curing.” Thin Solid Films, 516 3904–3909 (2008)

Gomathi, N, Eswaraiah, C, Neogi, S, “Surface Modification of Polycarbonate by Radio-Frequency Plasma and Optimization of the Process Variables with Response Surface Methodology.” J. Appl. Polym. Sci., 114 1557–1566 (2009)

Muir, BW, Thissen, H, Simon, GP, Murphy, PJ, Griesser, HJ, “Factors Affecting the Adhesion of Microwave Plasma Deposited Siloxane Films on Polycarbonate.” Thin Solid Films, 500 34–40 (2006)

Hofrichter, A, Bulkin, P, Drévillon, B, “Plasma Treatment of Polycarbonate for Improved Adhesion.” J. Vac. Sci. Technol. A, 20 245–250 (2002)

Zajíčková, L, Buršíková, V, Janča, J, “Protection Coatings for Polycarbonates Based on PECVD from Organosilicon Feeds.” Vacuum, 50 19–21 (1998)

Klemberg-Sapieha, JE, Poitras, D, Martinu, L, Yamasaki, NLS, Lantman, CW, “Effect of Interface on the Characteristics of Functional Films Deposited on Polycarbonate in Dual-Frequency Plasma.” J. Vac. Sci. Technol. A, 15 985–991 (1997)

Cui, L, Ranade, AN, Matos, MA, Pingree, LS, Frot, TJ, Dubois, G, Dauskardt, RH, “Atmospheric Plasma Deposited Dense Silica Coatings on Plastics.” ACS Appl. Mater. Inter., 4 6587–6598 (2012)

Lin, YS, Liao, YH, Weng, MS, “Enhanced Scratch Resistance of Polycarbonate by Low Temperature Plasma-Polymerized Organosilica.” Thin Solid Films, 517 5224–5230 (2009)

Bose, M, Bose, DN, Basa, DK, “Plasma Enhanced Growth, Composition and Refractive Index of Silicon Oxynitride Films.” Mater. Lett., 52 417–422 (2002)

Zajíčková, L, Buršíková, V, Peřina, V, Macková, A, Subedi, D, Janča, J, “Plasma Modification of Polycarbonates.” Surf. Coat. Technol., 142–144 449–454 (2001)

Yang, MR, Chen, KS, Hsu, ST, Wu, TZ, “Fabrication and Characteristics of SiO x Films by Plasma Chemical Vapor Deposition of Tetramethylorthosilicate.” Surf. Coat. Technol., 123 204–209 (2000)

Rats, D, Martinu, L, von Stebut, J, “Mechanical Properties of Plasma-Deposited SiO x N y Coatings on Polymer Substrates Using Low Load Carrying Capacity Techniques.” Surf. Coat. Technol., 123 36–43 (2000)

Rats, D, Hajek, V, Martinu, L, “Micro-Scratch Analysis and Mechanical Properties of Plasma-Deposited Silicon-Based Coatings on Polymer Substrates. Thin Solid Films, 340 33–39 (1999)

Tsubone, D, Hasebe, T, Kamijo, A, Hotta, A, “Fracture Mechanics of Diamond-like Carbon (DLC) Films Coated on Flexible Polymer Substrates.” Surf. Coat. Technol., 201 6423–6430 (2007)

Cuong, NK, Tahara, M, Yamauchi, N, Sone, T, “Diamond-like Carbon Films Deposited on Polymers by Plasma-Enhanced Chemical Vapor Deposition.” Surf. Coat. Technol., 174–175 1024–1028 (2003)

Damasceno, JC, Camargo, SS, Jr, Cremona, M, “Optical and Mechanical Properties of DLC-Si Coatings on Polycarbonate.” Thin Solid Films, 433 199–204 (2009)

Baek, SM, Shirafuji, T, Saito, N, Takai, O, “Adhesion Property of SiO x -Doped Diamond-like Carbon Films Deposited on Polycarbonate by Inductively Coupled Plasma Chemical Vapor Deposition.” Thin Solid Films, 519 6678–6682 (2011)

Damasceno, JC, Camargo, SS, “Plasma Deposition and Characterization of Silicon Oxide-Containing Diamond-like Carbon Films Obtained from CH4:SiH4:O2 Gas Mixtures.” Thin Solid Films, 516 1890–1897 (2008)

Damasceno, JC, Camargo, SS, Cremona, M, “Deposition and Evaluation of DLC–Si Protective Coatings for Polycarbonate Materials.” Thin Solid Films, 420–421 195–199 (2002)

Damasceno, JC, Camargo, SS, Cremona, M, “DLC-Si Protective Coatings for Polycarbonates.” Mater. Res., 6 19–23 (2002)

Varma, A, Palshin, V, Meletis, EI, “Structure–Property Relationship of Si-DLC Films.” Surf. Coat. Technol., 148 305–314 (2001)

Liu, Y, Shao, H, “Properties of ZnO: Al Films Deposited on Polycarbonate Substrate.” Vacuum, 83 1435–1437 (2009)

Yong, TK, Tou, TY, Teo, BS, “Pulsed Laser Deposition of Tin-Doped Indium Oxide (ITO) on Polycarbonate.” Appl. Surf. Sci., 248 388–391 (2005)

Ashfold, MNR, Claeyssens, F, Fuge, GM, Henley, SJ, “Pulsed Laser Ablation and Deposition of Thin Films.” Chem. Soc. Rev., 33 23–31 (2004)

Izumi, H, Ishihara, T, Yoshioka, H, Motoyama, M, “Electrical Properties of Crystalline ITO Films Prepared at Room Temperature by Pulsed Laser Deposition on Plastic Substrates.” Thin Solid Films, 411 32–35 (2002)

Gottmann, J, Kreutz, EW, “Pulsed Laser Deposition of Alumina and Zirconia Thin Films on Polymers and Glass as Optical and Protective Coatings.” Surf. Coat. Technol., 116–119 1189–1194 (1999)

Oliver, WC, Pharr, GM, “Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology.” J. Mater. Res., 19 3–20 (2004)

Wang, ZZ, Gu, P, Zhang, Z, “Indentation and Scratch Behavior of Nano-SiO2/Polycarbonate Composite Coating at the Micro/Nano-Scale.” Wear, 269 21–25 (2010)

Boentoro, W, Pflug, A, Szyszka, B, “Scratch Resistance Analysis of Coatings on Glass and Polycarbonate.” Thin Solid Films, 517 3121–3125 (2009)

Lahijania, YZK, Mohseni, M, Bastani, S, “Characterization of Mechanical Behavior of UV Cured Urethane Acrylate Nanocomposite Films Loaded with Silane Treated Nanosilica by the Aid of Nanoindentation and Nanoscratch Experiments.” Tribol. Int., 69 10–18 (2014)

Zhang, H, Zhang, H, Tang, L, Zhang, Z, Gu, L, Xu, Y, Eger, C, “Wear-Resistant and Transparent Acrylate-based Coating with Highly Filled Nanosilica Particles.” Tribol. Int., 43 83–91 (2010)

Zhang, L, Zeng, Z, Yang, J, Chen, Y, “Characterization and Properties of UV-Curable Polyurethane-Acrylate/Silica Hybrid Materials Prepared by the Sol-Gel Process.” Polym. Int., 53 1431–1435 (2004)

Soloukhin, VA, Posthumus, W, Brokken-Zijp, JCM, Loos, J, With, G, “Mechanical Properties of Silica–(Meth)acrylate Hybrid Coatings on Polycarbonate Substrate.” Polymer, 43 6169–6181 (2002)

Oh, IS, Park, NH, Suh, KD, “Mechanical and Surface Hardness Properties of Ultraviolet-Cured Polyurethane Acrylate Anionomer/Silica Composite Film.” J. Appl. Polym. Sci., 75 968–975 (2000)

Barletta, M, Vesco, S, Puopolo, M, Tagliaferri, V, “High Performance Composite Coatings on Plastics: UV-Curable Cycloaliphatic Epoxy Resins Reinforced by Graphene or Graphene Derivatives.” Surf. Coat. Technol., 272 322–336 (2015)

Kuo, SW, Chang, FC, “POSS Related Polymer Nanocomposites.” Prog. Polym. Sci., 36 1649–1696 (2011)

Castelvetro, V, Ciardelli, F, Vita, C, Puppo, A, “Hybrid Nanocomposite Films from Mono- and Multi-Functional POSS Copolyacrylates in Miniemulsion.” Macromol. Rapid Commun., 27 619–625 (2006)

Bizet, S, Galy, J, Gérard, JF, “Structure-Property Relationships in Organic-Inorganic Nanomaterials Based on Methacryl-POSS and Dimethacrylate Networks.” Macromolecules, 39 2574–2583 (2006)

Zhao, Y, Schiraldi, DA, “Thermal and Mechanical Properties of Polyhedral Oligomeric Silsesquioxane (POSS)/Polycarbonate Composites.” Polymer, 46 11640–11647 (2005)

Kopesky, ET, Haddad, TS, Cohen, RE, McKinley, GH, “Thermomechanical Properties of Poly(methyl methacrylate)s Containing Tethered and Untethered Polyhedral Oligomeric Silsesquioxanes.” Macromolecules, 37 8992–9004 (2004)

Raut, HK, Dinachali, SS, He, AY, Ganesh, VA, Saifullah, MSM, Law, J, Ramakrishna, R, “Robust and Durable Polyhedral Oligomeric Silsesquioxane-Based Anti-Reflective Nanostructures with Broadband Quasi-Omnidirectional Properties.” Energ. Environ. Sci., 6 1929–1937 (2013)

Jin, SB, Lee, JS, Choi, YS, Choi, IS, Han, JG, “High-Rate Deposition and Mechanical Properties of SiO x Film at Low Temperature by Plasma Enhanced Chemical Vapor Deposition with the Dual Frequencies Ultra High Frequency and High Frequency.” Thin Solid Films, 519 6334–6338 (2011)

Lin, YS, Weng, MS, Chung, TW, Huang, C, “Enhanced Surface Hardness of Flexible Polycarbonate Substrates Using Plasma-Polymerized Organosilicon Oxynitride Films by Air Plasma Jet under Atmospheric Pressure.” Surf. Coat. Technol., 205 3856–3864 (2011)

Lugscheider, E, Bobzin, K, Maes, M, Krämer, A, “On the Coating of Polymers—Basic Investigations.” Thin Solid Films, 459 313–317 (2004)

Hegemann, D, Brunner, H, Oehr, C, “Deposition Rate and Three-Dimensional Uniformity of RF Plasma Deposited SiO2 Films.” Surf. Coat. Technol., 142–144 849–855 (2001)

Rats, D, Martinu, L, von Stebut, J, “Mechanical Properties of Plasma-Deposited SiO x N y Coatings on Polymer Substrates Using Low Load Carrying Capacity Techniques.” Surf. Coat. Technol., 123 36–43 (2000)

Yoonessi, M, Gaier, JR, “Highly Conductive Multifunctional Graphene Polycarbonate Nanocomposites.” ACS Nano, 4 7211–7220 (2010)

Kim, HW, Macosko, CW, “Processing-Property Relationships of Polycarbonate/Graphene Composites.” Polymer, 50 3797–3809 (2009)

Bauhofer, W, Kovacs, JZ, “A Review and Analysis of Electrical Percolation in Carbon Nanotube Polymer Composites.” Compos. Sci. Technol., 69 1486–1498 (2009)

Sung, YT, Han, MS, Jung, JW, Lee, HS, Kum, CK, Joo, J, Kim, WN, “Rheological and Electrical Properties of Polycarbonate/Multi-Walled Carbon Nanotube Composites.” Polymer, 47 4434–4439 (2006)

Hornbostel, B, Pötschke, P, Kotz, J, Roth, S, “Single-Walled Carbon Nanotubes/Polycarbonate Composites: Basic Electrical and Mechanical Properties.” Phys. Stat. Sol (b), 243 3445–3451 (2006)

Pötschke, P, Bhattacharyya, AR, Janke, A, “Carbon Nanotube-Filled Polycarbonate Composites Produced by Melt Mixing and Their Use in Blends with Polyethylene.” Carbon, 42 965–969 (2004)

Pötschke, P, Abdel-Goad, M, Alig, I, Dudkin, S, Lellinger, D, “Rheological and Dielectrical Characterization of Melt Mixed Polycarbonate-Multiwalled Carbon Nanotube Composites.” Polymer, 45 8863–8870 (2004)

Pötschke, P, Fornes, TD, Paul, DR, “Rheological Behavior of Multiwalled Carbon Nanotube/Polycarbonate Composites.” Polymer, 43 3247–3255 (2002)

Jeon, SS, Han, SI, Jin, YH, Im, SS, “Polycarbonate-Based Conductive Film Prepared by Coating DBSA-Doped PEDOT/Sorbitol.” Synthetic Met., 148 287–291 (2005)

Lee, WJ, Kim, YJ, Kaang, SY, “Electrical Properties of Polyaniline/Sulfonated Polycarbonate Blends.” Synthetic Met., 113 237–243 (2000)

Roldughin, VI, Vysotskii, VV, “Percolation Properties of Metal-Filled Polymer Films. Structure and Mechanisms of Conductivity.” Prog. Org. Coat., 39 81–100 (2004)

Patole, A, Lubineau, G, “Carbon Nanotubes with Silver Nanoparticle Decoration and Conductive Polymer Coating for Improving the Electrical Conductivity of Polycarbonate Composites.” Carbon, 81 720–730 (2015)

Zhou, J, Lubineau, G, “Improving Electrical Conductivity in Polycarbonate Nanocomposites Using Highly Conductive PEDOT/PSS Coated MWCNTs.” ACS Appl. Mater. Inter., 5 6189–6200 (2013)

Kyrylyuk, A, Hermant, M, Schilling, T, Klumperman, B, Koning, C, van der Schoot, P, “Controlling Electrical Percolation in Multicomponent Carbon Nanotube Dispersions.” Nat. Nanotechnol., 6 364–369 (2011)

Hong, KP, Kim, SH, Yang, CW, Yun, WM, Nam, SJ, Jang, JY, “Photopatternable Poly(4-styrene sulfonicacid)-Wrapped MWNT Thin-Film Source/Drain Electrodes for Use in Organic Field-Effect Transistors.” ACS Appl. Mater. Inter., 3 74–79 (2011)

Hermant, MC, Schoot, P, Klumperman, B, Koning, CE, “Probing the Cooperative Nature of the Conductive Components in Polystyrene/Poly(3,4-ethylenedioxythiophene):Poly(styrene sulfonate)-Single-Walled Carbon Nanotube Composites.” ACS Nano, 4 2242–2248 (2010)

Kim, DSRY, Kim, YS, Choi, KW, Grunlan, JC, Yu, CH, “Improved Thermoelectric Behavior of Nanotube-filled Polymer Composites with Poly(3,4-ethylenedioxythiophene) Poly(styrenesulfonate).” ACS Nano, 4 513–523 (2010)

Hermant, M, Klumperman, B, Kyrylyuk, A, van der Schoot, P, Koning, C, “Lowering the Percolation Threshold of Single-Walled Carbon Nanotubes Using Polystyrene/Poly(3,4-ethylenedioxythiophene):Poly(styrene sulfonate) Blends.” Soft Matter, 5 878–885 (2009)

Amoli, HS, Shokatian, S, Abdous, M, “Thermal Annealing Combination with Pulse Nd-YAG Laser Treatment of ITO on Polycarbonate Using Spin Coating Process.” J. Sol-Gel Sci. Technol., 62 319–323 (2012)

Yong, TK, Tou, TY, Teo, BS, “Pulsed Laser Deposition of Tin-Doped Indium Oxide (ITO) on Polycarbonate.” Appl. Surf. Sci., 214 388–391 (2005)

Kim, DI, KIM, SJ, “AFM Observation of ITO Thin Films Deposited on Polycarbonate Substrates by Sputter Type Negative Metal Ion Source.” Surf. Coat. Technol., 176 23–29 (2003)

Kim, JS, Bae, JW, Kim, HJ, Lee, N-E, Yeom, GY, Oh, KH, “Effects of Oxygen Radical on the Properties of Indium Tin Oxide Thin Films Deposited at Room Temperature by Oxygen Ion Beam Assisted Evaporation.” Thin Solid Films, 377–378 103–108 (2000)

Wu, WF, Chiou, BS, “Deposition of Indium Tin Oxide Films on Polycarbonate Substrates by Radio-Frequency Magnetron Sputtering.” Thin Solid Films, 298 221–227 (1997)

Wu, WF, Chiou, BS, “Mechanical Properties of r.f. Magnetron Sputtered Indium Tin Oxide Films.” Thin Solid Films, 298 244–250 (1997)

Kulkarni, AK, Schulz, KH, Lim, TS, Khan, M, “Electrical, Optical and Structural Characteristics of Indium-Tin-Oxide Thin Films Deposited on Glass and Polymer Substrates.” Thin Solid Films, 308–309 1–7 (1997)

Minami, T, Sonohara, H, Kakumu, T, Takata, S, “Physics of Very Thin ITO Conducting Films with High Transparency Prepared by DC Magnetron Sputtering.” Thin Solid Films, 270 37–42 (1995)

Asakuma, N, Fukui, T, Toki, M, “Low-Temperature Synthesis of ITO Thin Films Using an Ultraviolet Laser for Conductive Coating on Organic Polymer Substrates.” J. Sol-Gel Sci. Technol., 27 91–95 (2003)

Aegerter, MA, Al-Dahoudi, N, “Wet-Chemical Processing of Transparent and Antiglare Conducting ITO Coating on Plastic Substrates.” J. Sol-Gel Sci. Technol., 27 81–89 (2003)

Al-Dahoudi, N, Aegerter, MA, “Wet Coating Deposition of ITO Coatings on Plastic Substrates.” J. Sol-Gel Sci. Technol., 26 693–697 (2003)

Al-Dahoudi, N, Bisht, H, Göbbert, C, Krajewski, T, Aegerter, MA, “Transparent Conducting, Anti-Static and Anti-Static-Anti-Glare Coatings on Plastic Substrates.” Thin Solid Films, 392 299–304 (2001)

Burgard, D, Goebbert, C, Nass, R, “Synthesis of Nanocrystalline, Redispersable Antimony-Doped SnO2 Particles for the Preparation of Conductive, Transparent Coatings.” J. Sol-Gel Sci. Technol., 13 789–792 (1998)

Sangermano, M, Foix, D, Kortaberria, G, Messori, M, “Multifunctional Antistatic and Scratch Resistant UV-Cured Acrylic Coatings.” Prog. Org. Coat., 76 1191–1196 (2013)

Wouters, MEL, Wolfs, DP, van der Linde, MC, Hovens, JHP, Tinnemans, AHA, “Transparent UV Curable Antistatic Hybrid Coatings on Polycarbonate Prepared by the Sol-Gel Method.” Prog. Org. Coat., 51 312–320 (2004)

Kim, HK, Kim, YB, Cho, JD, Hong, JW, “Synthesis and Characterization of Radiation-Curable Monomers for Antistatic Coatings.” Prog. Org. Coat., 48 34–42 (2003)

Haas, KH, Amberg-Schwab, S, Rose, K, “Functionalized Coating Materials Based on Inorganic-Organic Polymers.” Thin Solid Films, 351 198–203 (1999)

Jonas, F, Schrader, L, “Conductive Modifications of Polymers with Polypyrroles and Polythiophenes.” Synth. Met., 41 831–836 (1991)

Gardner, SV, Jeanne, L, Klein, S, Brady, BK, “Electrically Conductive Composition and Elements Containing Solubilized Polyaniline Complex and Solvent Mixture.” US Patent 5,716,550 (1998)

Jonas, F, Heywang, G, Schmidtberg, W, Heinze, J, Dietrich, M, “Method of Imparting Antistatic Properties to a Substrate by Coating the Substrate with a Novel Polythiophene.” UV Patent 5,035,926 (1991)

Yoshizumi, M, “Antistatic Transparent Coating Composition.” US Patent 4,431,764 (1984)

Glaubitt, W, Löbmann, P, “Antireflective Coatings Prepared by Sol-Gel Processing: Principles and Applications.” J. Eur. Ceram. Soc., 32 2995–2999 (2012)

Raut, HK, Ganesh, VA, Nair, AS, Ramakrishna, S, “Anti-Reflective Coatings: A Critical, In-depth Review.” Energy Environ. Sci., 4 3779–3804 (2011)

Schubert, MF, Mont, FW, Chhajed, S, Poxson, DJ, Kim, JK, Schubert, EF, “Design of Multilayer Antireflection Coatings Made from Co-Sputtered and Low-Refractive-Index Materials by Genetic Algorithm.” Opt. Express, 16 5290–5298 (2008)

Schulz, U, “Review of Modern Techniques to Generate Antireflective Properties on Thermoplastic Polymers.” Appl. Optics, 45 1608–1618 (2006)

Dobrowolski, JA, Poitras, D, Ma, P, Vakil, H, Acree, M, “Toward Perfect Antireflection Coatings: Numerical Investigation.” Appl. Optics, 41 3075–3083 (2002)

Chen, D, “Anti-Reflection (AR) Coatings Made by Sol-Gel Processes: A Review.” Sol. Energy Mater. Sol. Cells, 68 313–336 (2001)

Jewhurst, S, Kalyankar, N, “Magnesium Fluoride and Magnesium Oxyfluoride Based Anti-reflection Coating via Chemical Solution Deposition Processes.” US Patent 2014/0147594 A1 (2014)

Tanaka, H, Kobayashi, M, Sakakibara, T, “Method of Producing Magnesium Fluoride Coating, Antireflection Coating, and Optical Element.” US Patent 8,399,069 B2 (2013)

Hattori, H, “Anti-Reflection Surface with Particle Coating Deposited by Electrostatic Attraction.” Adv. Mater., 13 51–54 (2001)

Walheim, S, Schäffer, E, Mylnek, J, Steiner, U, “Nanophase-Separated Polymer Films as High-Performance Antireflection Coatings.” Science, 283 520–522 (1999)

Uhlmann, DR, Suratwala, T, Davidson, K, Boulton, JM, Teowee, G, “Sol-Gel Derived Coatings on Glass.” J. Non-Cryst. Solids, 218 113–122 (1997)

Minot, MJ, “Single-Layer, Gradient Refractive Index Antireflection Films Effective from 0.35 to 2.5 Microns.” J. Opt. Soc. Am., 66 515–519 (1976)

Moghal, J, Kobler, J, Sauer, J, Best, J, Gardener, M, Watt, ARR, Wakefield, G, “High-Performance, Single-Layer Antireflective Optical Coatings Comprising Mesoporous Silica Nanoparticles.” ACS Appl. Mater. Interfaces, 4 854–859 (2012)

Vincent, A, Babu, S, Brinley, E, Karakoti, A, Deshpande, S, Seal, S, “Role of Catalyst on Refractive Index Tunability of Porous Silica Antireflective Coatings by Sol-Gel Technique.” J. Phys. Chem. C, 111 8291–8298 (2007)

Bautista, MC, Morales, A, “Silica Antireflective Films on Glass Produced by the Sol-Gel Method.” Sol. Energy Mater. Sol. Cells, 80 217–225 (2003)

Menna, P, Francia, GD, Ferrara, VL, “Porous Silicon in Solar Cells: A Review and a Description of Its Application as an AR Coating.” Sol. Energy Mater. Sol. Cells, 37 13–24 (1995)

Thomas, IM, “Method for the Preparation of Porous Silica Antireflection Coatings Varying in Refractive Index from 1.22 to 1.44.” Appl. Opt., 31 (28) 6145–6149 (1992)

Galeotti, F, Trespidi, F, Timò, G, Pasini, M, “Broadband and Crack-Free Antireflection Coatings by Self-Assembled Moth Eye Patterns.” ACS Appl. Mater. Interfaces, 6 5827–5834 (2014)

Oh, SS, Choi, CG, Kim, YS, “Fabrication of Micro-lens Arrays with Moth-Eye Antireflective Nanostructures Using Thermal Imprinting Process.” Microelectron. Eng., 87 2328–2331 (2010)

Chen, Q, Hubbard, G, Shields, PA, Liu, C, Allsopp, DWE, Wang, WN, Abbot, S, “Broadband Moth-Eye Antireflection Coatings Fabricated by Low-cost Nanoimprinting.” Appl. Phys. Lett., 94 263118-1–263118-3 (2009)

Sun, CH, Jiang, P, Jiang, B, “Broadband Moth-Eye Antireflection Coatings on Silicon.” Appl. Phys. Lett., 92 (061112) 1–3 (2008)

Clapham, PB, Hutley, MC, “Reduction of Lens Reflection by the “Moth Eye” Principle.” Nature, 244 281–282 (1973)

Mazur, M, Wojcieszak, D, Kaczmarek, D, Domaradzki, J, Song, S, Gibson, D, Placido, F, Mazur, P, Kalisz, M, Poniedzialek, A, “Functional Photocatalytically Active and Scratch Resistant Antireflective Coating Based on TiO2 and SiO2.” Appl. Surf. Sci., 380 165–171 (2016)

Li, D, Wan, D, Zhu, X, Wang, Y, Han, Z, Han, S, Shan, Y, Huang, F, “Broadband Antireflection TiO2–SiO2 Stack Coatings with Refractive-Index-Grade Structure and Their Applications to Cu(In, Ga)Se2 Solar Cells.” Sol. Energy Mater. Sol. Cells, 130 505–512 (2014)

Mazur, M, Wojcieszak, D, Domarazki, J, Kaczmarek, D, Song, S, Placido, F, “TiO2/SiO2 Multilayer as an Antireflective and Protective Coating Deposited by Microwave Assisted Magnetron Sputtering.” Opto-Electron. Rev., 21 233–238 (2013)

Hinczewski, DS, Hinczewski, M, Tepehan, FZ, Tepehan, GG, “Optical Filters from SiO2 and TiO2 Multi-layers Using Sol–Gel Spin Coating Method.” Sol. Energy Mater. Sol. Cells, 87 181–196 (2005)

Jeong, SH, Kim, JK, Kim, BS, Shim, SH, Lee, BT, “Characterization of SiO2 and TiO2 Films Prepared Using rf Magnetron Sputtering and Their Application to Anti-Reflection Coating.” Vacuum, 76 507–515 (2004)

Martinet, C, Paillard, V, Gagnaire, A, Joseph, J, “Deposition of SiO2 and TiO2 Thin Films by Plasma Enhanced Chemical Vapor Deposition for Antireflection Coating.” J. Non-Cryst. Solids, 216 77–82 (1997)

Chen, D, Yan, Y, Westernberg, E, Niebauer, D, Sakaitani, N, Chaudhuri, SR, Sato, Y, Takamatsu, M, “Development of Anti-Reflection (AR) Coating on Plastic Panels for Display Applications.” J. Sol-Gel Sci. Technol., 19 77–82 (2000)

Chunder, A, Etcheverry, K, Wadsworth, S, Boreman, GD, Zhai, L, “Fabrication of Anti-Reflection Coatings on Plastics Using the Spraying Layer-by-Layer Self-Assembly Technique.” J. Soc. Inf. Display, 17 389–395 (2009)

Hiller, J, Mendelsohn, JD, Rubner, MF, “Reversibly Erasable Nanoporous Anti-reflection Coatings from Polyelectrolyte Multilayers.” Nat. Mater., 1 59–63 (2002)

Yang, S, Rubner, MF, “Micropatterning of Polymer Thin Films with pH-Sensitive and Cross-linkable Hydrogen-Bonded Polyelectrolyte Multilayers.” J. Am. Chem. Soc., 124 2100–2101 (2002)

Yam, CM, Kakkar, AK, “Molecular Self-Assembly of Dihydroxy-Terminated Molecules via Acid-Base Hydrolytic Chemistry on Silica Surfaces: Step-by-Step Multilayered Film Construction.” Langmuir, 15 3807–3815 (1999)

Weng, KW, Huang, YP, “Preparation of TiO2 Thin Films on Glass Surfaces with Self-Cleaning Characteristics for Solar Concentrators.” Surf. Coat. Technol., 231 201–204 (2013)

Lai, Y, Tang, Y, Gong, J, Gong, D, Chi, L, Lin, C, Chen, Z, “Transparent Superhydrophobic/Superhydrophilic TiO2-Based Coatings for Self-Cleaning and Anti-Fogging.” J. Mater. Chem., 22 7420–7426 (2012)

Xi, B, Verma, LK, Li, J, Bhatia, CS, Danner, AJ, Yang, HS, Zeng, HC, “TiO2 Thin Films Prepared via Adsorptive Self-Assembly for Self-Cleaning Applications.” ACS Appl. Mater. Inter., 4 1093–1102 (2012)

Euvananont, C, Junin, C, Inpor, K, Limthongkul, P, Thanachayanont, C, “TiO2 Optical Coating Layers for Self-Cleaning Applications.” Ceram. Int., 34 1067–1071 (2008)

Latthe, S, Liu, S, Terashima, C, Nakata, K, Fujishima, A, “Transparent, Adherent, and Photocatalytic SiO2-TiO2 Coatings on Polycarbonate for Self-Cleaning Applications.” Coatings, 4 497–507 (2014)

Fateh, R, Dillert, R, Bahnemann, D, “Preparation and Characterization of Transparent Hydrophilic Photocatalytic TiO2/SiO2 Thin Films on Polycarbonate.” Langmuir, 29 3730–3739 (2013)

Kesmez, Ö, Erdem Çamurlu, H, Burunkaya, E, Arpaç, E, “Sol-Gel Preparation and Characterization of Anti-Reflective and Self-Cleaning SiO2-TiO2 Double-Layer Nanometric Films.” Sol. Energy Mater. Sol. Cells, 93 1833–1839 (2009)

Liu, Z, Zhang, X, Murakami, T, Fujishima, A, “Sol-Gel TiO2/SiO2 Bilayer Films with Self-Cleaning and Antireflection Properties.” Sol. Energy Mater. Sol. Cells, 92 1434–1438 (2008)

Guan, K, “Relationship between Photocatalytic Activity, Hydrophilicity and Self-Cleaning Effect of TiO2/SiO2 Films.” Surf. Coat. Technol., 191 155–160 (2005)

Li, H, Jiang, M, Hu, D, Yan, Y, Li, Q, Dong, L, Xiong, C, “Solvent-Free Zirconia Nanofluid/Silica Single-Layer Multifunctional Hybrid Coatings.” Colloid. Surface. A, 464 26–32 (2015)

Prado, R, Beobide, G, Marcaide, A, Goikoetxea, J, Aranzabe, A, “Development of Multifunctional Sol-Gel Coatings: Anti-Reflection Coatings with Enhanced Self-Cleaning Capacity.” Sol. Energy Mater. Sol. Cells, 94 1081–1088 (2010)

Zhao, X, Zhao, Q, Yu, J, Liu, B, “Development of Multifunctional Photoactive Self-Cleaning Glasses.” J. Non-Cryst. Solids, 354 1424–1430 (2008)

Okada, M, Yamada, Y, Jin, P, Tazawa, M, Yoshimura, K, “Fabrication of Multifunctional Coating Which Combines Low-E Property and Visible-Light-Responsive Photocatalytic Activity.” Thin Solid Films, 442 217–221 (2003)

Kuhr, M, Bauer, S, Rothhaar, U, Wolff, D, “Coatings on Plastics with the PICVD Technology.” Thin Solid Films, 442 107–116 (2003)

Acknowledgment

This work was supported by the Korea Institute of Planning & Evaluation for Technology in Food, Agriculture, Forestry & Fisheries (iPET) Grant 112050-3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, N. Recent progress of functional coating materials and technologies for polycarbonate. J Coat Technol Res 14, 21–34 (2017). https://doi.org/10.1007/s11998-016-9837-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9837-x