Abstract

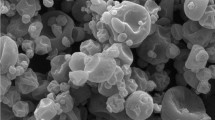

The reactive extrusion technique is efficient in the incorporation of bioactive compounds for active packaging development. The application of curcumin, a strong antioxidant in its pure, isolated form to obtain active packaging has already been investigated; however, the use of water-soluble curcumin (WSC) in thermoplastic starch/poly(butylene adipate-co-terephthalate) (TPS/PBAT) films has not yet been investigated. It is important to determine how WSC would affect starch esterification reaction during reactive extrusion (REx). The use of WSC at 0.5%wt led to an increase in tensile strength, elongation at break, and Young’s modulus. A reduction in starch esterification was observed; however, an improvement in TPS/PBAT compatibility was detected by infrared spectroscopy, X-ray diffraction, and scanning electron microscopy images. It is worth noting that WSC addition resulted in an increase in the film’s solubility and water vapor permeability, due to the hydrophilic character of the WSC. The films were used to package chia oil, and the oxidative stability data were evaluated by UV-Vis spectroscopy coupled with principal component analysis. The addition of WSC (0.5%wt) in the films led to the improvement of the oil oxidative stability, suggesting that using water-soluble curcumin may be a promising alternative to active packaging in the case of reactive extruded films.

Similar content being viewed by others

References

de Almeida, M., de Rocha, B. A., Francisco, C. R. L., Miranda, C. G., Santos, P. D. D. F., De Araújo, P. H. H., et al. (2018a). Evaluation of the in vivo acute antiinflammatory response of curcumin-loaded nanoparticles. Food & Function, 9(1), 440–449. https://doi.org/10.1039/c7fo01616f.

Andrade-Molina, T. P. D. C., Shirai, M. A., Victória Eiras Grossmann, M., & Yamashita, F. (2013). Active biodegradable packaging for fresh pasta. LWT - Food Science and Technology, 54(1), 25–29. https://doi.org/10.1016/j.lwt.2013.05.011.

ASTM, (1996) E96-00: standard test methods for water vapor transmission of materials.

ASTM. (2002). American Society for Testing and Materials. D 882-02: Standard test method for tensile properties of thin plastic sheeting. ASTM International, 14, 1–10.

Benavides, S., Villalobos-Carvajal, R., & Reyes, J. E. (2012). Physical, mechanical and antibacterial properties of alginate film: Effect of the crosslinking degree and oregano essential oil concentration. Journal of Food Engineering, 110(2), 232–239. https://doi.org/10.1016/j.jfoodeng.2011.05.023.

Brandelero, R. P. H., Yamashita, F., & Grossmann, M. V. E. (2010). The effect of surfactant Tween 80 on the hydrophilicity, water vapor permeation, and the mechanical properties of cassava starch and poly(butylene adipate-co-terephthalate) (PBAT) blend films. Carbohydrate Polymers, 82(4), 1102–1109. https://doi.org/10.1016/j.carbpol.2010.06.034.

de Campos, S. S., de Oliveira, A., Moreira, T. F. M., da Silva, T. B. V., da Silva, M. V., Pinto, J. A., Bilck, A. P., Gonçalves, O. H., Fernandes, I. P., Barreiro, M. F., Yamashita, F., Valderrama, P., Shirai, M. A., & Leimann, F. V. (2019). TPCS/PBAT blown extruded films added with curcumin as a technological approach for active packaging materials. Food Packaging and Shelf Life, 22, 1–9. https://doi.org/10.1016/j.fpsl.2019.100424.

Cardoso, L. G., Pereira Santos, J. C., Camilloto, G. P., Miranda, A. L., Druzian, J. I., & Guimarães, A. G. (2017). Development of active films poly (butylene adipate co-terephthalate) – PBAT incorporated with oregano essential oil and application in fish fillet preservation. Industrial Crops and Products, 108(January), 388–397. https://doi.org/10.1016/j.indcrop.2017.06.058.

Chen, B., Shen, C., Chen, S., & Chen, A. F. (2010). Ductile PLA modified with methacryloyloxyalkyl isocyanate improves mechanical properties. Polymer, 51(21), 4667–4672. https://doi.org/10.1016/j.polymer.2010.08.028.

Chen, C., Kuo, W., & Lai, L. (2009). Effect of surfactants on water barrier and physical properties of tapioca starch/decolorized hsian-tsao leaf gum films. Food Hydrocolloids, 23(3), 714–721. https://doi.org/10.1016/j.foodhyd.2008.06.006.

da Silva, J. B. A., Santana, J. S., Lucas, A. D. A., Passador, F. R., da Silva Costa, L. A., Pereira, F. V., & Druzian, J. I. (2019a). PBAT/TPS-nanowhiskers blends preparation and application as food packaging. Journal of Applied Polymer Science, 47699(26), 1–10. https://doi.org/10.1002/app.47699.

da Silva, T. B. V., Moreira, T. F. M., de Oliveira, A., Bilck, A. P., Gonçalves, O. H., Ferreira, I. C. F. R., et al. (2019b). Araucaria angustifolia (Bertol.) Kuntze extract as a source of phenolic compounds in TPS/PBAT active films. Food & Function, 10(12), 7697–7706. https://doi.org/10.1039/C9FO01315F.

de Almeida, M. M. C., Francisco, C. R. L., de Oliveira, A., de Campos, S. S., Bilck, A. P., Fuchs, R. H. B., et al. (2018b). Textural, color, hygroscopic, lipid oxidation, and sensory properties of cookies containing free and microencapsulated chia oil. Food and Bioprocess Technology, 1–14. https://doi.org/10.1007/s11947-018-2057-x.

De Oliveira Pizzoli, A. P., Yamashita, F., Gonçalves, O. H., Shirai, M. A., & Leimann, F. V. (2017). The effect of gelatin amount on the properties of PLA/TPS/gelatin extruded sheets. Polimeros, 27(1), 27–34. https://doi.org/10.1590/0104-1428.2181.

Della Valle, G., Vergnes, B., & Lourdin, D. (2007). Viscous properties of thermoplastic starches from different botanical origin. International Polymer Processing, 22(5), 471–479. https://doi.org/10.3139/217.2057.

Dufresne, A. (2014). Crystalline starch based nanoparticles. Current Opinion in Colloid and Interface Science, 19(5), 397–408. https://doi.org/10.1016/j.cocis.2014.06.001.

EC. Commission Regulation (European Commission-EC), (2009) N° 450/2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. https://eur-lex.europa.eu/legal-content/PT/TXT/HTML/?uri=CELEX:32009R0450&from=EN

de Maria Vaz Conceição, E., Filho, A. L. M. M., da Silva Roque, L., de Moura do Amaral Pires, F., Webster, T. J., Marciano, F. R., & Lobo, A. O. (2019). In vivo evaluation of the genotoxic effects of poly nanohydroxyapatite scaffolds for bone regeneration. Materials, 12(1130), 1–16.

Garcia, P. S., Eiras Grossmann, M. V., Yamashita, F., Mali, S., Dall’Antonia, L. H., & Barreto, W. J. (2011). Citric acid as multifunctional agent in blowing films of starch/PBAT. Quimica Nova, 34(9), 1507–1510. https://doi.org/10.1590/S0100-40422011000900005.

Garcia, P. S., Grossmann, M. V. E., Shirai, M. A., Lazaretti, M. M., Yamashita, F., Muller, C. M. O., & Mali, S. (2014). Improving action of citric acid as compatibiliser in starch/polyester blown films. Industrial Crops and Products, 52, 305–312. https://doi.org/10.1016/j.indcrop.2013.11.001.

Gonçalves, R. P., Março, P. H., & Valderrama, P. (2014). Thermal edible oil evaluation by UV–Vis spectroscopy and chemometrics. Food Chemistry, 163, 83–86. https://doi.org/10.1016/j.foodchem.2014.04.109.

Gonçalves, T. R., Rosa, L. N., Torquato, A. S., da Silva, L. F. O., Março, P. H., Gomes, S. T. M., Matsushita, M., & Valderrama, P. (2020). Assessment of Brazilian monovarietal olive oil in two different package systems by using data fusion and chemometrics. Food Analytical Methods, 13(1), 86–96. https://doi.org/10.1007/s12161-019-01511-w.

Hablot, E., Dewasthale, S., Zhao, Y., Zhiguan, Y., Shi, X., Graiver, D., & Narayan, R. (2013). Reactive extrusion of glycerylated starch and starch-polyester graft copolymers. European Polymer Journal, 49(4), 873–881. https://doi.org/10.1016/j.eurpolymj.2012.12.005.

Jacob, J., Thomas, S., Loganathan, S., & Valapa, R. B. (2020). Antioxidant incorporated biopolymer composites for active packaging. In Zhang, Y. (Ed.), Processing and development of polysaccharide-based biopolymers for packaging applications (pp. 239–260). Elsevier Inc. https://doi.org/10.1016/b978-0-12-818795-1.00010-1.

Jiménez, A., Fabra, M. J., Talens, P., & Chiralt, A. (2012). Edible and biodegradable starch films: A review. Food and Bioprocess Technology, 5(6), 2058–2076. https://doi.org/10.1007/s11947-012-0835-4.

Kim, I., Viswanathan, K., Kasi, G., Thanakkasaranee, S., Sadeghi, K., & Seo, J. (2020). ZnO nanostructures in active antibacterial food packaging: preparation methods, antimicrobial mechanisms, safety issues, future prospects, and challenges. Food Reviews International, 00(00), 1–29. https://doi.org/10.1080/87559129.2020.1737709.

Leal, I. L., da Silva Rosa, Y. C., da Silva Penha, J., Cruz Correia, P. R., da Silva Melo, P., Guimarães, D. H., et al. (2019). Development and application starch films: PBAT with additives for evaluating the shelf life of Tommy Atkins mango in the fresh-cut state. Journal of Applied Polymer Science, 136(43), 1–19. https://doi.org/10.1002/app.48150.

Leimann, V. F., Gonçalves, O. H., Sorita, G. D., Rezende, S., Bona, E., Fernandes, I. P. M., Ferreira, I. C. F. R., & Barreiro, M. F. (2019). Heat and pH stable curcumin-based hydrophilic colorants obtained by the solid dispersion technology assisted by spray-drying. Chemical Engineering Science, 205, 248–258. https://doi.org/10.1016/j.ces.2019.04.044.

Lendvai, L., Apostolov, A., & Karger-Kocsis, J. (2017). Characterization of layered silicate-reinforced blends of thermoplastic starch (TPS) and poly(butylene adipate-co-terephthalate). Carbohydrate Polymers, 173, 566–572. https://doi.org/10.1016/j.carbpol.2017.05.100.

Liu, W., Liu, S., Wang, Z., Dai, B., Liu, J., Chen, Y., Zeng, G., He, Y., Liu, Y., & Liu, R. (2019). Preparation and characterization of reinforced starch-based composites with compatibilizer by simple extrusion. Carbohydrate Polymers, 223(January), 115122. https://doi.org/10.1016/j.carbpol.2019.115122.

Lv, S., Gu, J., Cao, J., Tan, H., & Zhang, Y. (2015). Effect of annealing on the thermal properties of poly (lactic acid)/starch blends. International Journal of Biological Macromolecules, 74, 297–303. https://doi.org/10.1016/j.ijbiomac.2014.12.022.

Martins, A. B., & Santana, R. M. C. (2016). Effect of carboxylic acids as compatibilizer agent on mechanical properties of thermoplastic starch and polypropylene blends. Carbohydrate Polymers, 135, 79–85. https://doi.org/10.1016/j.carbpol.2015.08.074.

Menzel, C. (2020). Improvement of starch films for food packaging through a three-principle approach: antioxidants, cross-linking and reinforcement. Carbohydrate Polymers, 250, 116828. https://doi.org/10.1016/j.carbpol.2020.116828.

Muller, J., González-Martínez, C., & Chiralt, A. (2017). Combination of poly(lactic) acid and starch for biodegradable food packaging. Materials, 10(8), 1–22. https://doi.org/10.3390/ma10080952.

Nafchi, A. M., Moradpour, M., Saeidi, M., & Alias, A. K. (2013). Thermoplastic starches: properties, challenges, and prospects. Starch/Staerke, 65(1–2), 61–72. https://doi.org/10.1002/star.201200201.

Nunes, M. A. B. S., Marinho, V. A. D., Falcão, G. A. M., Canedo, E. L., Bardi, M. A. G., & Carvalho, L. H. (2018). Rheological, mechanical and morphological properties of poly (butylene adipate-co-terephthalate)/thermoplastic starch blends and its biocomposite with babassu mesocarp. Polymer Testing, 70, 281–288. https://doi.org/10.1016/j.polymertesting.2018.07.009.

Ochoa, T. A., Almendárez, B. E. G., Reyes, A. A., Pastrana, D. M. R., López, G. F. G., Belloso, O. M., & González, C. R. (2017). Design and characterization of corn starch edible films including beeswax and natural antimicrobials. Food and Bioprocess Technology, 10(1), 103–114. https://doi.org/10.1007/s11947-016-1800-4.

Olivato, J. B., Nobrega, M. M., Müller, C. M. O., Shirai, M. A., Yamashita, F., & Grossmann, M. V. E. (2013). Mixture design applied for the study of the tartaric acid effect on starch/polyester films. Carbohydrate Polymers, 92(2), 1705–1710. https://doi.org/10.1016/j.carbpol.2012.11.024.

Park, S. I., & Zhao, Y. (2004). Incorporation of a high concentration of mineral or vitamin into chitosan-based films. Journal of Agricultural and Food Chemistry, 52(7), 1933–1939. https://doi.org/10.1021/jf034612p.

Peng, N., Gu, L., Li, J., Chang, C., Li, X., & Su, Y. (2017). Films based on egg white protein and succinylated casein cross-linked with transglutaminase. Food and Bioprocess Technology, 10(8), 1422–1430. https://doi.org/10.1007/s11947-017-1901-8.

Raquez, J.-M., Nabar, Y., Narayan, R., & Dubois, P. (2006). Finite strain 3D thermoviscoelastic constitutive model. Polymer Engineering & Science, 48(9), 1747–1754. https://doi.org/10.1002/pen.

Sailaja, R. R. N., & Chanda, M. (2001). Use of maleic anhydride-grafted polyethylene as compatibilizer for HDPE-tapioca starch blends: Effects on mechanical properties. Journal of Applied Polymer Science, 80(6), 863–872. https://doi.org/10.1002/1097-4628(20010509)80:6<863::AID-APP1164>3.0.CO;2-R.

Schwach, E., & Avérous, L. (2004). Starch-based biodegradable blends: Morphology and interface properties. Polymer International, 53(12), 2115–2124. https://doi.org/10.1002/pi.1636.

Seligra, P. G., Moura, L. E., Famá, L., Druzian, J. I., & Goyanes, S. (2016). Influence of incorporation of starch nanoparticles in PBAT/TPS composite films. Polymer International, 65(8), 938–945. https://doi.org/10.1002/pi.5127.

Shahlari, M., & Sunggyu, L. (2012). Mechanical and morphological properties of poly(butylene adipate-co-terephthalate) and poly(lactic acid) blended with organically modified silicate layers. Polymer Engineering and Science, 52(7), 13–17. https://doi.org/10.1002/pen.

Shi, R., Zhang, Z., Liu, Q., Han, Y., Zhang, L., Chen, D., & Tian, W. (2007). Characterization of citric acid/glycerol co-plasticized thermoplastic starch prepared by melt blending. Carbohydrate Polymers, 69(4), 748–755. https://doi.org/10.1016/j.carbpol.2007.02.010.

da Silva, M. N., de Matos Fonseca, J., Feldhaus, H. K., Soares, L. S., Valencia, G. A., de Campos Maduro, C. E., et al. (2019c). Physical and morphological properties of hydroxypropyl methylcellulose films with curcumin polymorphs. Food Hydrocolloids, 97(March), 105217. https://doi.org/10.1016/j.foodhyd.2019.105217.

De Souza, K. C., Correa, L. G., Barlati, T., Fernandes, T., Moreira, M., De Oliveira, A., et al. (2020). Soy protein isolate films incorporated with pinhão (Araucaria angustifolia (Bertol.) Kuntze) extract for potential use as edible oil active packaging. Food and Bioprocess Technology, 13(6), 998–1008.

Subhan, M. A., Alam, K., Rahaman, M. S., Rahman, M. A., & Awal, R. (2013). Synthesis and characterization of metal complexes containing curcumin (C21H20O6) and study of their anti-microbial activities and DNA-binding properties. Journal of Scientific Research, 6(1), 97–109. https://doi.org/10.3329/jsr.v6i1.15381.

Toro-Márquez, L. A., Merino, D., & Gutiérrez, T. J. (2018). Bionanocomposite films prepared from corn starch with and without nanopackaged Jamaica (Hibiscus sabdariffa) flower extract. Food and Bioprocess Technology, 11(11), 1955–1973. https://doi.org/10.1007/s11947-018-2160-z.

Van Nong, H., Hung, L. X., Thang, P. N., Chinh, V. D., Van Vu, L., Dung, P. T., et al. (2016). Fabrication and vibration characterization of curcumin extracted from turmeric (Curcuma longa) rhizomes of the northern Vietnam. Springer Plus, 5(1), 1147. https://doi.org/10.1186/s40064-016-2812-2.

Venturini, L. H., Moreira, T. F. M., da Silva, T. B. V., de Almeida, M. M. C., Francisco, C. R. L., de Oliveira, A., de Campos, S. S., Bilck, A. P., de Souza Leone, R., Tanamati, A. A. C., Gonçalves, O. H., & Leimann, F. V. (2018). Partial substitution of margarine by microencapsulated chia seeds oil in the formulation of cookies. Food and Bioprocess Technology, 2014(1), 77–87. https://doi.org/10.1007/s11947-018-2188-0.

Wei, D., Wang, H., Ziaee, Z., Chibante, F., Zheg, A., & Xiao, H. (2016). Non-leaching antimicrobial biodegradable PBAT films through a facile and novel approach. Materials Science and Engineering C, 58, 986–991. https://doi.org/10.1016/j.msec.2015.09.023.

Wójcicki, K., Khmelinskii, I., Sikorski, M., & Sikorska, E. (2015). Near and mid infrared spectroscopy and multivariate data analysis in studies of oxidation of edible oils. Food Chemistry, 187, 416–423. https://doi.org/10.1016/j.foodchem.2015.04.046.

Yildirim, S., Röcker, B., Pettersen, M. K., Nilsen-Nygaard, J., Ayhan, Z., Rutkaite, R., Radusin, T., Suminska, P., Marcos, B., & Coma, V. (2018). Active packaging applications for food. Comprehensive Reviews in Food Science and Food Safety, 17(1), 165–199. https://doi.org/10.1111/1541-4337.12322.

Zehetmeyer, G., Meira, S. M. M., Scheibel, J. M., De Oliveira, R. V. B., Brandelli, A., & Soares, R. M. D. (2016). Influence of melt processing on biodegradable nisin-PBAT films intended for active food packaging applications. Journal of Applied Polymer Science, 133(13), 1–10. https://doi.org/10.1002/app.43212.

Acknowledgements

The authors thank the “Central Analítica Multiusuário da UTFPR Campo Mourão” (CAMulti-CM) for the analyses. Fernanda V. Leimann (process 039/2019) and Patrícia Valderrama (process 033/2019) thank Fundação Araucária (CP 15/2017- Programa de Bolsas de Produtividade em Pesquisa e Desenvolvimento Tecnológico).

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mücke, N., da Silva, T.B.V., de Oliveira, A. et al. Use of Water-Soluble Curcumin in TPS/PBAT Packaging Material: Interference on Reactive Extrusion and Oxidative Stability of Chia Oil. Food Bioprocess Technol 14, 471–482 (2021). https://doi.org/10.1007/s11947-021-02584-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02584-4