Abstract

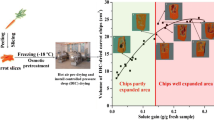

The research targeted on the production of an innovative shelf-stable cheese of high quality, through the combinatory effect of osmotic dehydration (OD) as pretreatment and conventional air-drying. The optimum OD processing conditions (process time/temperature, concentration of osmotic solution, food to OD agent ratio) were determined through a kinetic study of the effect of OD parameters on the water activity (aw) and water/solid transport phenomena, organoleptic and quality characteristics of the white cheese in cubes. Through Fick’s second law for mass transfer, water and solid diffusion coefficients were determined. Taking into consideration the aw, the quality, and organoleptic characteristics of the final product, the optimum OD conditions were selected as 15 °C process temperature, food to osmotic agent ratio 1:4 (w/w), concentration of osmotic agent 65% to glycerol, and treatment time 30 min. The final moisture and aw of the OD-treated product were calculated as 40% and 0.88, respectively. The time of OD-pretreated product for air-drying at 40, 55, and 67 °C to 5% residual moisture was reduced by 35, 51, and 65% respectively. The selected air-drying conditions were 67 °C for 4 h. Quality parameters of the final white cheese product were studied during its storage at 15–40 °C, and the shelf life was estimated as 6 months at ambient temperature.

Similar content being viewed by others

References

Achanta, S., & Okos, M. R. (1996). Predicting the quality of dehydrated foods and biopolymers. Research needs and opportunities. Journal of Drying Technology, 14(6), 1329–1368.

Ahmed, I., Qazi, I. M., & Jamal, S. (2016). Developments in osmotic dehydration technique for the preservation of fruits and vegetables. Innovative Food Science & Emerging Technologies, 34, 29–43.

Andreou, V., Tsironi, T., Dermesonlouoglou, E., Katsaros, G., & Taoukis, P. (2018). Combinatory effect of osmotic and high pressure processing on shelf life extension of animal origin products-application to chilled chicken breast fillets. Journal of Food Packaging and Shelf Life, 15, 43–51.

Anifantakis, E. M., & Moatsou, G. (2006). Feta and other Balkan cheeses. Production methods, manufacturing stages and properties. In A. Y. Tamime (Ed.), Brined Cheeses Manual (pp. 43–76). Oxford: Blackwell Publishing Ltd.

Antonio, G. C., Azoubel, P. M., Alves, D. G., El-Aouar, A. A., & Murr, F. E. X. (2004). Osmotic dehydration of papaya (carica papaya l.): influence of process variables (pp. 1998–2004). Sao Paulo: Proceedings of the 14th International Drying Symposium.

Castell-Palou, A., & Simal, S. (2011). Heat pump drying kinetics of a pressed type cheese. LWT- Food Science and Technology, 44, 489–494.

Castell-Palou, A., Rosselló, C., Femenia, A., Bon, J., & Simal, S. (2011). Moisture profiles in cheese drying determined by TD-NMR: Mathematical modeling of mass transfer. Journal of Food Engineering, 104(4), 525–531.

Crank, J. (1975). The mathematics of diffusion (2nd ed.). London: Clarendon Press-Oxford.

Dimakopoulou-Papazoglou, D., & Katsanidis, E. (2017). Effect of maltodextrin, sodium chloride, and liquid smoke on the mass transfer kinetics and storage stability of osmotically dehydrated beef meat. Journal of Food and Bioprocess Technology, 10(11), 2034–2045.

Dermesonlouoglou, E., Andreou, V., Alexandrakis, Z., Katsaros, G., Giannakourou, M., & Taoukis, P. (2017). The hurdle effect of osmotic pretreatment and high-pressure cold pasteurisation on the shelf-life extension of fresh-cut tomatoes. International Journal of Food Science & Technology, 52(4), 916–926.

Dermesonlouoglou, E., Chalkia, A., & Taoukis, P. (2018). Application of osmotic dehydration to improve the quality of dried goji berry. Journal of Food Engineering, 232, 36–43.

Dermesonlouoglou, E. K., Angelikaki, F., Giannakourou, M. C., Katsaros, G. K., & Taoukis, P. S. (2019a). Minimally processed fresh-cut peach and apricot snacks of extended shelf-life by combined osmotic and high pressure processing. Journal of Food and Bioprocess Technology, 12(3), 371–386.

Dermesonlouoglou, E. K., Pantelaiaki, K., Andreou, V., Katsaros, G. K., & Taoukis, P. S. (2019b). Osmotic pretreatment for producing novel dehydrated tomatoes and cucumbers. Journal of Food Processing and Preservation. https://doi.org/10.1111/jfpp.13968.

Food Code. (2005). Recommendations of the United States public health service. Food and Drug Administration, National Technical Information Service Publication, PB2005-102200.

Fucà, N., McMahon, D. J., Caccamo, M., Tuminello, L., La Terra, S., Manenti, M., & Licitra, G. (2012). Effect of brine composition and brining temperature on cheese physical properties in Ragusano cheese. Journal of Dairy Science, 95(1), 460–470.

Giannoglou, M., Karra, Z., Platakou, E., Katsaros, G., Moatsou, G., & Taoukis, P. (2016). Effect of high pressure treatment applied on starter culture or on semi-ripened cheese in the quality and ripening of cheese in brine. Journal of Innovative Food Science & Emerging Technologies, 38, 312–320.

Igoshi, A., Sato, Y., Kameyama, K., & Murata, M. (2017). Galactose is the limiting factor for the browning or discoloration of cheese during storage. Journal of Nutritional Science and Vitaminology, 63(6), 412–418.

Ispir, A., & Toğrul, İ. T. (2009). Osmotic dehydration of apricot: Kinetics and the effect of process parameters. Journal of Chemical Engineering Research and Design, 87, 166–180.

Karathanos, V. T., Kostaropoulos, E., & Saravacos, G. D. (1995). Air drying of osmotically dehydrated fruits. Journal of Drying Technology, 13(5&7), 1503–1521.

Leistner, L. (2000). Basic aspect of food preservation by hurdle technology. International Journal of Food Microbiology, 55(1–3), 181–186.

Lu, Y., & McMahon, D. J. (2015). Effects of sodium chloride salting and substitution with potassium chloride on whey expulsion of Cheddar cheese. Journal of Dairy Science, 98(1), 78–88.

Miraei Ashtiani, S. H., Salarikia, A., & Golzarian, M. R. (2017). Analyzing drying characteristics and modeling of thin layers of peppermint leaves under hot-air and infrared treatments. Information Processing in Agriculture, 4(2), 128–139.

Moreira, R., Chenlo, F., Torres, M. D., & Vazquez, G. (2007). Effect of stirring in the osmotic dehydration of chestnut using glycerol solutions. LWT- Food Science and Technology, 40(9), 1507–1514.

Nguyen, M. P., Ngo, T. T., & Le, T. D. (2019). Experimental and numerical investigation of transport phenomena and kinetics for convective shrimp drying. Case studied in thermal engineering, 14, 1000465.

Onwude, D. I., Hashim, N., Janius, R. B., Nawi, N. M., & Abdan, K. (2016). Modeling the thin-layer drying of fruits and vegetables: a review. Comprehensive Reviews in Food Science and Food Safety, 15(3), 599–618.

Ozgen, F. (2015). Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Journal of Heat and Mass Transfer, 51(3), 343–353.

Panagiotou, N. M., Karathanos, V. T., & Maroulis, Z. (1999). Effect of osmotic agents on osmotic dehydration of fruits. Journal of Drying Technology, 17(1-2), 175–189.

Phisut, N. (2012). Factors affecting mass transfer during osmotic dehydration of fruits. International Food Research Journal, 19(1), 7–18.

Pinho, A. R. C., Assis, F. R., Peres, A. P., Pintado, M. E., & Morais, A. M. M. B. (2017). Dehydration of cheese by hot air, microwave and freeze-drying. Scientific Study & Research Chemistry & Chemical Engineering, Biotechnology, Food Industry, 18(4), 455–460.

Praveen Kumar, D. G., Hebbar, U., & Ramesh, M. N. (2006). Suitability of thin layer models for infrared–hot air-drying of onion slices. LWT- Food Science and Technology, 39(6), 700–705.

Rahman, M. S., & Labuza, T. P. (2007). Water activity and food preservation. In M. S. Rahman (Ed.), In: Handbook of Food Preservation (2nd ed., pp. 447–476). Boca Raton: CRC Press.

Rahman, M. S. (2008). Dehydration and microstructure. In C. Ratti (Ed.), Advances in Food Dehydration (p. 97). Boca Raton: CRC Press, Taylor & Francis Group.

Rastogi, N. K., & Raghavarao, K. (1997). Water and solute diffusion coefficients of carrot as a function of temperature and concentration during osmotic dehydration. Journal of Food Engineering, 34(4), 429–441.

Rastogi, N. K., & Niranjan, K. (1998). Enhanced mass transfer during osmotic dehydration of high pressure treated pineapple. Journal of Food Engineering, 63, 508–511.

Rastogi, N. K., Angersbach, A., & Knorr, D. (2000). Synergistic effect of high hydrostatic pressure pretreatment and osmotic stress on mass transfer during osmotic dehydration. Journal of Food Engineering, 45(1), 25–31.

Rastogi, N. K., Raghavarao, K. S. M. S., Niranjan, K., & Knorr, D. (2002). Recent developments in osmotic dehydration: Methods to enhance mass transfer. Trends in Food Science and Technology, 13(2), 48–59.

Rastogi, N. K., & Raghavarao, K. S. M. S. (2004). Mass transfer during osmotic dehydration of pineapple considering Fickian diffusion in cubical configuration. Lebensmittel-Wissenschaft + Technologie, 37, 43–47.

Sacilik, K., Konuralp Elicin, A., & Unal, G. (2006). Drying kinetics of Uryani plum in a convective hot-air dryer. Journal of Food Engineering, 76, 362–368.

Schär, W., & Bosset, J. O. (2002). Chemical and physico-chemical changes in processed cheese and ready-made fondue during storage. A review. Lebensmittel-Wissenschaft und Technologie, 35, 15–20.

Tirado, D. F., González-Morelo, K. J., Puerta, M. J., Ahumada, O. Y., & Correa, D. A. (2018). Osmotic dehydration and hot-air drying of pineapple (Ananas comosus). International Journal of Engineering and Technology. https://doi.org/10.21817/ijet/2017/v9i6/170906112.

Tortoe, C. (2010). A review of osmodehydration for food industry. African Journal of Food Science, 4(6), 303–324.

Uribe, E., Miranda, M., Vega-Gálvez, A., Quispe, I., Clavería, R., & Di Scala, K. (2011). Mass transfer modelling during osmotic dehydration of jumbo squid (Dosidicus gigas): Influence of temperature on diffusion coefficients and kinetic parameters. Journal of Food and Bioprocess Technology, 4(2), 320–326.

Veeramachaneni, K., Vladislavleva, K., Burland, M., Parcon, J., & O’Reilly, U. M. (2010). Evolutionary optimization of flavors. In J. Branke et al. (Eds.), GECCO ‘10: Proceedings of the 12th annual conference on genetic and evolutionary computation (pp. 1291–1298). Portland: ACM.

Verma, D., Kaushik, N., & Srinivasa Rao, P. (2014). Application of high hydrostatic pressure as a pretreatment for osmotic dehydration of banana slices (Musa cavendishii) Finish-dried by dehumidified air drying. Journal of Food and Bioprocess Technology, 7(5), 1281–1297.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Giannoglou, M., Koumandraki, H., Andreou, V. et al. Combined Osmotic and Air Dehydration for the Production of Shelf-Stable White Cheese. Food Bioprocess Technol 13, 1435–1446 (2020). https://doi.org/10.1007/s11947-020-02484-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-020-02484-z