Abstract

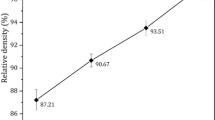

Aluminum–silicon alloy reinforced with titanium diboride particles (2 wt.%, 5 wt.%, and 7 wt.%) were successfully synthesized using a stir-casting method. Dipotassium titanium hexafluoride and potassium tetrafluoroborate salts were used to obtain an in situ titanium diboride phase in a molten matrix. These in situ composites have shown significant improvements in their mechanical properties, such as Young’s modulus, yield strength, ultimate tensile strength and micro-hardness compared to the base alloy. X-ray diffraction patterns of the obtained metal matrix composites confirms the formation of titanium diboride particles. The microstructures were studied using field-emission scanning electron microscopy. The in situ-formed titanium diboride particles were found uniformly distributed with good interfacial bonding. Reinforcement particles were predominantly in cubical, spherical, and hexagonal shapes. The fracture surfaces of the composites contained fine dimples, and some microcracks were generated and propagated through cleavage or facet zones.

Similar content being viewed by others

References

A. Macke, B. F. Schultz, and P. Rohatgi, in Advanced Materials and Processes (Almere: ASM International, 2012), pp. 19–23.

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, Mater. Sci. Eng., A 280, 37 (2000).

T.S. Srivatsan and V.K. Vasudevan, JOM 51, 42 (1999).

G.S. Cole and A.M. Sherman, Mater. Charact. 35, 3 (1995).

A. Kumar, M.M. Mahapatra, P.K. Jha, N.R. Mandal, and V. Devuri, Mater. Des. 59, 406 (2014).

S.L. Pramod, S.R. Bakshi, and B.S. Murty, J. Mater. Eng. Perform. 24, 2185 (2015).

A. Baradeswaran and A. Elaya Perumal, Compos. Part B 54, 146 (2013).

F. Saba, F. Zhang, S. Liu, and T. Liu, Compos. Part B 167, 7 (2019).

S.V. Sujith and R.S. Mulik, J. Alloys Compd. 812, 152131 (2020).

W.O. Soboyejo and T.S. Srivatsan, Advanced Structural Materials: Properties, Design Optimization, and Applications (Boca Raton: CRC, 2006).

T.S. Srivatsan and J. Lewandowski, Advanced Structural Materials: Properties, Design Optimization, and Applications, ed. W.O. Soboyejo and T.S. Srivatsan (Boca Raton: CRC, 2006), pp. 275–357.

M.K. Surappa, Sadhana 28, 319 (2003).

B. Ralph, H.C. Yuen, and W.B. Lee, J. Mater. Process. Technol. 63, 339 (1997).

T.S. Srivatsan, J. Mater. Sci. 31, 1375 (1996).

L.C. Davis, C. Andres, and J.E. Allison, Mater. Sci. Eng., A 249, 40 (1998).

A. Kumar, P.K. Jha, and M.M. Mahapatra, J. Mater. Eng. Perform. 23, 743 (2014).

J. Hemanth, Wear 258, 1732 (2005).

N. Kumar, G. Gautam, R.K. Gautam, A. Mohan, and S. Mohan, Tribol. Int. 97, 313 (2016).

B.S.S. Daniel, V.S.R. Murthy, and G.S. Murty, J. Mater. Process. Technol. 68, 132 (1997).

J. Karloopia, S. Mozammil, and P. Jha, J. Compos. Sci. 3, 28 (2019).

A. Kennedy, A. Karantzalis, and S. Wyatt, J. Mater. Sci. 4, 933 (1999).

K.K. Chawla, Composite Materials: Science and Engineering, 3rd ed. (New York: Springer, 2012).

S. Morankar, M. Mandal, N. Kourra, M.A. Williams, R. Mitra, and P. Srirangam, JOM 71, 4050 (2019).

H. Yi, N. Ma, X. Li, Y. Zhang, and H. Wang, Mater. Sci. Eng., A 419, 12 (2006).

B.S. Yigezu, P.K. Jha, and M.M. Mahapatra, Mater. Manuf. Process. 28, 969 (2013).

S. Mozammil, J. Karloopia, R. Verma, and P.K. Jha, J. Alloys Compd. 826, 17 (2020).

S. Kumar, V. Subramanya sarma, and B.S. Murty, J. Alloys Compd. 479, 268 (2009).

L. Zhang, J. Gao, M. Huang, and E. Wang, JOM 71, 4144 (2019).

S. Lakshmi, L. Lu, and M. Gupta, J. Mater. Process. Technol. 73, 160 (1998).

Q. Yang, D.L. Cheng, J. Liu, L. Wang, Z. Chen, M.L. Wang, S.Y. Zhong, Y. Wu, G. Ji, and H.W. Wang, Mater. Charact. 155, 109834 (2019).

Y.M. Youssef, R.J. Dashwood, and P.D. Lee, Compos. Part A 36, 747 (2005).

J. Karloopia, S. Mozammil, and P.K. Jha, Mater. Today Proc. 5, 17260 (2018).

S. Mozammil, J. Karloopia, R. Verma, and P.K. Jha, J. Alloys Compd. 793, 454 (2019).

X. Wang, R. Brydson, A. Jha, and J. Ellis, J. Microsc. 196, 137 (1999).

T. Wang, Z. Chen, Y. Zheng, Y. Zhao, H. Kang, and L. Gao, Mater. Sci. Eng., A 605, 22 (2014).

C.S. Kim, I. Sohn, M. Nezafati, J.B. Ferguson, B.F. Schultz, Z. Bajestani-Gohari, P.K. Rohatgi, and K. Cho, J. Mater. Sci. 48, 4191 (2013).

C.S. Ramesh, S. Pramod, and R. Keshavamurthy, Mater. Sci. Eng., A 528, 4125 (2011).

T.P.D. Rajan, R.M. Pillai, B.C. Pai, K.G. Satyanarayana, and P.K. Rohatgi, Compos. Sci. Technol. 67, 3369 (2007).

F. Toptan, A. Kilicarslan, A. Karaaslan, M. Cigdem, and I. Kerti, Mater. Des. 31, S87 (2010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karloopia, J., Mozammil, S. & Jha, P.K. Influence of In Situ Titanium Diboride Particulate Reinforcement on Mechanical Properties of Aluminum–Silicon Based Metal Matrix Composites. JOM 72, 2927–2936 (2020). https://doi.org/10.1007/s11837-020-04245-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04245-x