Abstract

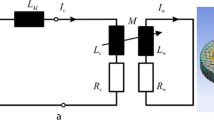

Electromagnetic (EM) induction heating of open top risers represents an energy-efficient method to preserve mass feeding whilst allowing for the use of a smaller riser and thus higher casting yield. Numerical simulation results for an ill-designed, concentric riser and casting assembly predicting the EM field characteristics and solidification behavior in such systems are presented herein. A vector potential formulation of the EM field was used and solved using a hybrid control volume/integral method, featuring temperature-dependent electrical conductivity. The heat transfer equation with phase change was also solved using the control volume technique. The computed results showed that use of induction heating could shift the hot spot from the casting to the riser. It was also found that use of higher coil frequencies produced a guard heating effect at the periphery of the riser, which was then applied using a new L-shaped coil geometry.

Similar content being viewed by others

References

J.F. Schifo and J.T. Radia, Theoretical/Best Practice Energy Use in Metalcasting Operations (Keramida Environmental, 2004), https://www.energy.gov/sites/prod/files/2013/11/f4/doebestpractice_052804.pdf. Accessed 15 Sept 2015.

K. Kermeli, R. Deuchler, E. Worrell, and E. Masanet, Energy Efficiency and Cost Saving Opportunities for Metal Casting: An ENERGY STAR Guide for Energy and Plant Managers (US Department of Energy, 2016), https://www.energystar.gov/buildings/tools-and-resources/energy_efficiency_and_cost_saving_opportunities_metal_casting. Accessed 15 Sept 2015.

N. Chvorinov, Giesserei 27, 177 (1940).

R.L. Lewis, Optimization of Casting Rigging Design, MS Thesis, The Ohio State University, 1983.

I. Ciobanu, S. Munteanu, A. Crisan, T. Bedo, and V. Monescu, Int. J. Metalcast. 8, 63 (2014).

R.A. Flinn, Fundamentals of Metal Casting (Boston: Addison-Wesley, 1963).

H.F. Bishop, E.T. Myskowski, and W.S. Pellini, AFS Trans. 63, 271 (1955).

H.D. Merchant, in AFS Transaction Proceedings of the 63rd Annual Meeting, p. 13 (1959).

S. Kossy and R.F. Boddey, Exothermically Reacting Sleeve for Risers, US Patent 2,591,105, 1952, https://patents.google.com/patent/US2591105. Accessed 23 June 2018.

A.C. Midea, Foundry Manag. Technol. 127, 50 (1999).

Z. Ignaszak and P. Popielarski, Mater. Sci. Forum 514, 1438 (2006).

R.A. Hardin, T.J. Williams, and C. Beckermann, Riser Sleeve Properties for Steel Castings and the Effect of Sleeve Type on Casting Yield, MS Thesis, University of Iowa, 2013.

T.J. Williams, Determination of Effective Riser Sleeve Thermophysical Properties for Simulation and Analysis of Riser Sleeve Performance, MS Thesis, University of Iowa, 2016.

R.C. Aufderheide, R.E. Showman, J. Close, and E.J. Zins, in AFS Transaction Proceedings of the 106th Annual Congress, p. 917 (2002).

S. Zinn and S.L. Semiatin, Elements of Inducation Heating (Materials Park: ASM International, 1988).

C.J. Xu, Y.X. Zeng, Z.L. Wang, J. Li, S.L. Li, and X.J. Zhang, Metallurgija 55, 593 (2016).

S. Tonseth, Making Greener Ship Propellers (ScienceNordic, 2014), http://sciencenordic.com/making-greener-ship-propellers. Accessed 11 Oct 2016.

S. Takahashi, Y. Nakagawa, and Y. Hosoda, Method for Heating a Riser of Molten Refractory Material, US Patent 4,460,524, 1984.

K. Hirayama, Y. Matsubara, A. Sakai, T. Sugiyama, K. Yokoo, T. Yamashita, T. Hirayama, H. Sugihara, K. Matsuo, and A. Yokoi, Metal Casting Method, Japanese Patent 4,494,868, 1997.

G. Poole and L. Nastac, J. Manuf. Sci. Prod. 15, 13 (2015).

M.R. Cox and G.M. Poole, Numerical simulation of electromagnetic and heat transfer phenomena in inductively heated risers.CFD Modeling and Simulation in Materials Processing 2018, ed. L. Nastac, K. Pericleous, A. Sabau, L. Zhang, and B. Thomas (New York: Springer, 2018), pp. 53–62.

J.L. Meyer, N. El-Kaddah, and J. Szekely, IEEE Trans. Magn. 23, 1806 (1987).

S.V. Patankar, Numerical Heat Transfer and Fluid Flow (New York: Hemisphere, 1980).

J. Szekely and N.J. Themelis, Rate Phenomena in Process Metallurgy (New York: Wiley, 1971).

A. De and T. DebRoy, Sci. Techol. Weld Join 11, 143 (2006).

N.V. Kopchenova and I.A. Maron, Computational Mathematics (Moscow: Mir, 1972), pp. 63–67.

K.C. Mills, Recommended Values of Thermophysical Properties for Selected Commercial Alloys (Cambridge: Woodhead, 2002), pp. 50–53.

S.I. Bakhtiyarov, R.A. Overfelt, and S.G. Teodorescu, J. Mater. Sci. 26, 4643 (2001).

Zircar Refractory Composites, RSLE-501 Cylinders (December 2017), http://www.zrci.com/wdpr/wp-content/uploads/2018/03/ZRCI-201-Rev-12-27-17.pdf. Accessed 03 Mar 2018.

F.P. Incropera and D.P. Dewitt, Fundamentals of Heat Transfer, 2nd ed. (New York: Wiley, 1981).

W. Kurz and D.J. Fisher, Fundamentals of Solidification (Rockport: Trans Tech Publications, 1986).

T. Campanella, C. Charbon, and M. Rappaz, Scr. Mater. 49, 1029 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Poole, G.M., Cox, M.R. Influence of Coil Configuration and Operating Conditions on Heat Transfer in Inductively Heated Risers. JOM 71, 40–47 (2019). https://doi.org/10.1007/s11837-018-3201-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3201-9